How Steel Coil Packing Machines Improve Steel Processing in Europe?

Are you a factory manager in Europe, constantly battling production bottlenecks, rising labor costs, and safety concerns on your steel processing line? I understand the pressure you face. Every minute of downtime, every damaged coil, and every workplace injury chips away at your bottom line and your peace of mind. You’re looking for solutions that genuinely make a difference, not just another piece of equipment.

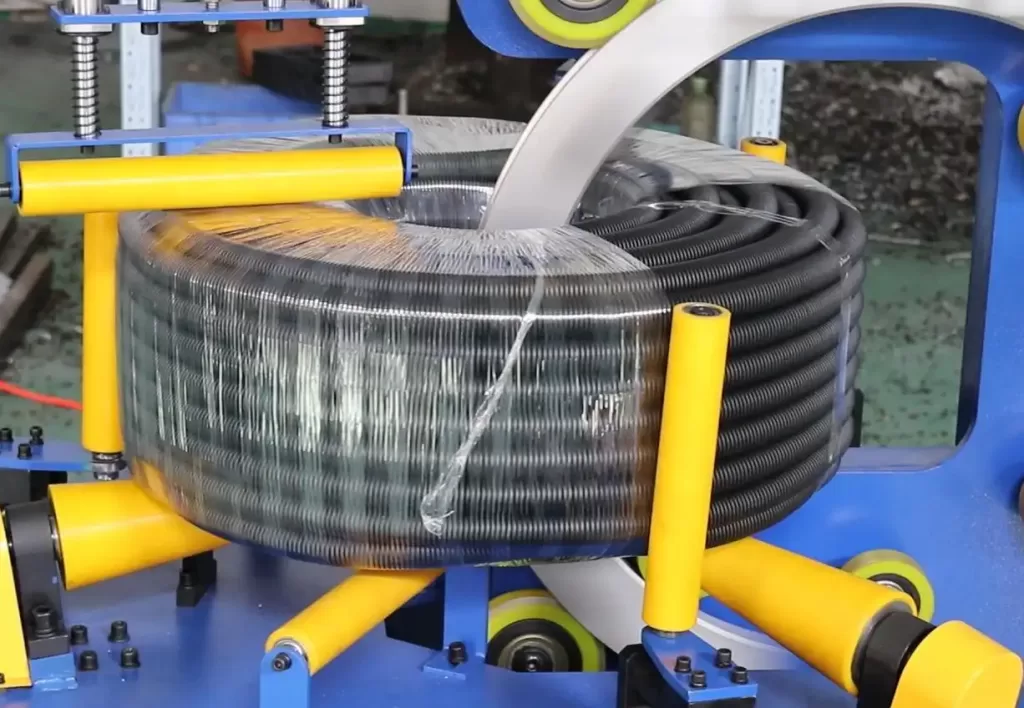

Steel coil packing machines are transforming the European steel processing industry by automating critical end-of-line operations, directly addressing the core challenges of efficiency, safety, and product quality. These specialized machines streamline the packaging of heavy steel coils and wires, reducing reliance on manual labor, minimizing handling risks, and ensuring products arrive at their destination in perfect condition, which is vital for maintaining competitive edge in the demanding European market.

It’s clear that the traditional ways of packing steel coils are no longer enough for the fast-paced and high-standard European market. But how exactly do these machines deliver on their promise? Let’s dive deeper into the specific ways they empower businesses like yours to overcome daily hurdles and achieve sustainable growth.

1. How do manual packing processes hurt European steel plants?

Imagine your factory floor. Heavy steel coils move slowly, needing many hands to wrap them. This scene is common in many European steel plants. This reliance on manual labor creates big problems. It makes your operations slow and less safe. It also adds significant costs to your business.

Manual steel coil packing processes in European steel plants often lead to major inefficiencies, increased safety risks, and higher operational costs. Workers struggle with the physical demands of handling heavy coils, causing slow packing speeds and frequent production bottlenecks. This method also raises the risk of workplace injuries, product damage, and inconsistent packaging quality, which can hurt your reputation and lead to financial losses.

Let me tell you, I’ve seen this firsthand. When I started in this industry, manual packing was the norm. But I quickly learned its limitations. For a factory manager like you, Michael, these challenges are real and impactful. They directly affect your plant’s ability to meet targets and grow.

-

Efficiency Bottlenecks:

- Slow Processing Speed: Manual wrapping is time-consuming. Each coil takes a long time to pack. This creates a backlog at the end of the production line. (slow packing efficiency)

- High Labor Dependence: You need many workers for this job. Finding and keeping skilled labor is hard. This increases your operational expenses. (labor intensive packing)

- Inconsistent Output: Human packing quality can change. Some days are better than others. This leads to varied packaging standards. (inconsistent packaging quality)

-

Safety Hazards:

- Risk of Injury: Moving and wrapping heavy steel coils is dangerous. Workers can get strains, sprains, or worse. (workplace safety risks)

- Fatigue and Errors: Long hours of hard physical work lead to fatigue. Tired workers make more mistakes. These mistakes can cause accidents. (manual handling injuries)

- High Insurance Costs: More injuries mean higher insurance premiums. This adds to your operating costs. It also affects employee morale. (industrial accident costs)

-

Product Damage and Costs:

- Coil Damage: During manual handling, steel coils can get scratched or dented. This reduces their value. It can lead to customer complaints. (steel coil damage)

- Material Waste: Sometimes, packing materials are not used efficiently. This results in waste. It adds to material costs. (packaging material waste)

- Loss of Profit: All these issues—slow speed, injuries, damage—reduce your overall profit. They make it harder to compete. (profitability reduction)

I know how much you value reliable equipment. But even the best machines upstream cannot fix a bottleneck at the packing stage if it is manual. It’s like having a high-performance engine with a slow transmission. Your entire operation suffers. This is why addressing manual processes is not just about efficiency; it’s about the health and future of your entire factory. It’s about ensuring every part of your process runs as smoothly as the steel itself. You deserve solutions that genuinely uplift your entire operation, not just patch it up.

2. How do steel coil packing machines boost efficiency in Europe?

In Europe, the demand for fast, reliable steel products is always high. This puts immense pressure on manufacturers. Many factory managers ask me how they can keep up. My answer is often simple: look at your packing line. Steel coil packing machines are not just machines; they are powerful tools for efficiency.

Steel coil packing machines significantly boost efficiency in European steel processing by automating the entire packaging process. This automation leads to faster wrapping cycles, reduces labor requirements, and ensures consistent package quality. By eliminating manual bottlenecks and integrating seamlessly with existing production lines, these machines enable higher throughput and quicker delivery times, which are crucial for staying competitive in Europe’s industrial landscape.

When I founded FHOPEPACK, my goal was always to help factories run better. I’ve seen countless clients, even in tough markets like Europe, transform their operations by embracing smart automation. For factory managers like Michael, who prioritize output and cost control, these machines are a game-changer. They directly tackle the efficiency challenges that keep you up at night.

-

Streamlined Operations:

- 🚀 Faster Cycle Times: Automatic machines can wrap coils much quicker than humans. This means more coils packed per hour. It directly increases your overall production capacity. (increased packing speed)

- 🔄 Continuous Flow: These machines integrate into your production line. They ensure a smooth, uninterrupted flow from manufacturing to dispatch. This prevents bottlenecks at the final stage. (integrated production line)

- 🤖 Reduced Labor Needs: One machine can do the work of several people. This frees up your workforce. You can assign them to other important tasks. This optimizes your human resources. (labor optimization)

-

Cost Reductions and ROI:

- 💰 Lower Labor Costs: With fewer workers needed for packing, your payroll costs go down. This is a direct saving. It improves your profit margins. (reduced operating expenses)

- 📉 Minimized Material Waste: Automated machines use packing materials precisely. They cut down on excess use. This saves you money on film, stretch wrap, or paper. (packaging material efficiency)

- 📈 Quick Return on Investment (ROI): The savings from labor, reduced damage, and increased throughput add up quickly. Many factories see their investment pay off in a short time. This makes it a smart business decision. (fast ROI machinery)

-

Enhanced Throughput and Market Responsiveness:

- 🏭 Higher Production Capacity: Your factory can handle more orders. It can process larger volumes of steel coils. This expands your market reach. (enhanced production volume)

- ⏱️ Shorter Lead Times: Faster packing means products are ready for shipment sooner. You can meet customer deadlines more easily. This improves customer satisfaction. (quicker delivery times)

- 🌍 Competitive Edge in Europe: In the highly competitive European market, efficiency is key. These machines give you a significant advantage. They allow you to deliver faster and at a lower cost. (European market competitiveness)

Consider Michael’s situation: he needs to boost output and control costs. An automated steel coil packing machine directly addresses both. It’s not just about wrapping; it’s about optimizing your entire workflow, making your factory more agile and profitable. I built my factory by focusing on these kinds of solutions. I saw how a smart investment in automation can lead to financial independence and business growth for my clients. It’s about empowering your business to do more with less, which is always a winning strategy, especially in today’s economic climate.

3. How do automatic systems improve safety and product quality for steel coils?

Safety is non-negotiable in any factory. Product quality directly impacts your reputation. When I talk to factory managers in Europe, I often hear concerns about manual handling injuries and damaged goods. Automatic steel coil packing systems offer clear answers to both. They are designed to protect both your workers and your valuable products.

Automatic steel coil packing systems significantly improve workplace safety by removing workers from dangerous manual handling tasks involving heavy coils, drastically reducing the risk of injuries. Simultaneously, these systems ensure superior product quality through consistent, secure, and damage-free packaging. This prevents external factors from harming the steel coils during storage and transit, which is critical for maintaining high standards and avoiding costly returns in the European market.

My own journey from a factory employee to a factory owner taught me the true value of safety and quality. I saw the risks workers took every day. I also understood the cost of damaged products. That’s why I am so passionate about solutions that address these vital areas. For someone like Michael, dealing with high injury risks and product loss, these systems are not just an improvement; they are a fundamental necessity.

A. Enhancing Worker Safety 👷♀️

-

Eliminating Manual Handling:

- Reduced Physical Strain: Machines lift, rotate, and wrap the heavy coils. Workers no longer need to manually move or secure these massive objects. This prevents back injuries, strains, and other musculoskeletal disorders.

- Fewer Accidents: Taking human hands away from moving machinery and heavy loads significantly lowers the chance of crushes, cuts, and other serious accidents.

- Safer Work Environment: The overall factory floor becomes a much safer place. Workers can focus on supervision and maintenance, rather than risky physical labor.

-

Compliance and Morale:

- Meeting Safety Regulations: European safety standards are strict. Automatic systems help your factory comply with these rules easily. This avoids penalties and legal issues.

- Improved Employee Morale: When workers feel safe, they are happier and more productive. A commitment to safety shows you care about your team. This reduces employee turnover.

B. Securing Product Quality 🛡️

-

Consistent Packaging:

- Uniform Wrapping: Machines apply packing materials with consistent tension and overlap. This creates a uniform and secure package every time. (consistent packaging quality)

- Precise Material Application: Whether it’s stretch film, paper, or woven fabric, the machine applies it exactly as programmed. This protects all surfaces of the coil.

- Damage Prevention:

- Edge Protection: Automated systems can apply edge protectors or specialized wraps. This guards against dents and scratches during internal transport and external shipping.

- Moisture and Dust Barrier: The tight, consistent wrap creates an effective barrier. It protects the steel from moisture, dust, and corrosion. This is especially important for long-distance transport.

- Stable Loads: Properly wrapped coils are more stable. They are less likely to shift during transit. This prevents damage to the product itself and to the transport vehicle.

-

Customer Satisfaction and Reputation:

- Fewer Customer Complaints: When products arrive in perfect condition, customers are happy. This reduces complaints and returns.

- Enhanced Brand Image: Delivering high-quality, perfectly packed products builds trust and strengthens your brand reputation. This is vital for repeat business and growth in Europe.

- Higher Product Value: Pristine products command better prices. They maintain their full market value. This directly impacts your profitability.

By investing in these systems, you are not just buying equipment. You are investing in the well-being of your employees and the quality assurance of your products. This proactive approach to safety and quality is what sets leading European manufacturers apart. It’s a philosophy I’ve always believed in and a key reason why FHOPEPACK focuses on reliable, intelligent packing solutions.

4. Why is choosing the right packing machine partner crucial for European businesses?

You’ve heard how automatic packing machines can help your factory. But owning a machine is one thing. Having a trusted partner is another. I know Michael has faced disappointment with suppliers before. This is why choosing the right partner, one who truly understands your needs, is critical for European businesses. It’s about more than just buying equipment; it’s about building a relationship that supports your growth.

Choosing the right packing machine partner is crucial for European businesses because it ensures long-term operational success, reliable support, and tailored solutions. A knowledgeable partner, unlike a mere seller, offers expertise beyond the machine itself, understands your unique production challenges, and provides consistent after-sales service, which is essential for maximizing ROI and minimizing costly downtime in the demanding European industrial environment.

I founded FHOPEPACK because I believe in partnership. My journey from employee to factory owner showed me that success comes from helping others succeed. I’ve seen what happens when companies choose the wrong supplier. You end up with machines that don’t fit your needs, poor support, and endless headaches. That’s why I emphasize that a good partner is a long-term asset.

A. Expertise and Understanding 🧠

-

Industry Knowledge:

- Deep Insight: A true partner understands the nuances of steel processing and packing. They know the challenges of heavy industries. They can speak your language.

- Problem Solvers: They don’t just sell machines. They offer solutions to your specific production bottlenecks and safety concerns. They anticipate your needs.

- Tailored Advice: They can recommend the best machine for your factory size, product type, and production volume. They won’t push a one-size-fits-all solution.

-

Experience Matters:

- Proven Track Record: Look for companies with a long history of successful installations. They should have experience with diverse clients.

- Randal’s Experience: (My Story) My personal experience building a successful packing machine factory from the ground up gives me a unique perspective. I understand the entire lifecycle of a packing machine, from design to daily operation, because I’ve lived it. This means I can offer insights that purely sales-driven companies cannot.

B. Reliable After-Sales Support 🛠️

-

Installation and Training:

- Seamless Setup: A good partner ensures smooth installation. They also provide comprehensive training for your staff. This gets your machine running optimally from day one.

- Operational Confidence: Your team will feel confident operating and maintaining the new equipment. This reduces errors and downtime.

-

Maintenance and Parts:

- Preventative Maintenance: They offer maintenance schedules and services. This keeps your machines in top condition. It prevents unexpected breakdowns.

- Readily Available Parts: A reliable partner has spare parts in stock. This means quick repairs. It minimizes your production delays.

- Technical Assistance: They provide prompt technical support. You can get help when you need it. This ensures continuous operation.

C. Long-Term Partnership 🤝

- Growth and Adaptation:

- Scalable Solutions: As your factory grows, your partner should be able to offer upgrades or new solutions. They help your packing capabilities evolve with your business.

- Innovation: They keep you informed about new technologies and improvements. This helps you stay competitive in the European market.

- Trust and Reliability: Building a trusting relationship means you have peace of mind. You know your packing needs are in capable hands. This allows you to focus on your core business.

In Europe, the steel industry demands excellence. Your packing machine partner should reflect that same commitment. This is where I want FHOPEPACK to stand out. We aim to be that trusted advisor, like Fengding and Wuxi Bihui, offering not just machines but deep knowledge and unwavering support. It’s about providing the solutions that truly empower you to achieve your goals—higher safety, better efficiency, and sustained profitability.

My Insights!

My journey in the packing machine industry has been incredibly rewarding. I started as an employee, learned the ropes, and eventually built a successful packing machine factory. This experience taught me that the real value lies not just in the machinery itself, but in truly understanding the challenges our clients face. I’ve helped many businesses achieve financial independence by optimizing their operations, just as I did for myself. This firsthand knowledge—from the factory floor to the CEO’s office—allows me to offer insights that go beyond typical sales pitches. I understand your pressure points, whether it’s the need for greater efficiency in coil packing, enhancing safety in steel wire packing, or ensuring a robust return on investment. My commitment now is to share this expertise, to help you navigate the complexities of automation, and to find the solutions that genuinely drive your business forward. It’s about giving back to an industry that has given me so much, ensuring that you, too, can master your packing processes and achieve your own success.

Conclusion

Steel coil packing machines are essential for European steel processing, driving efficiency, safety, and quality. Partnering with experts like FHOPEPACK ensures you gain a reliable steel coil packing line solution for lasting success.

```markdown

# How Steel Coil Packing Machines Improve Steel Processing in Europe?

Are you a factory manager in Europe, constantly battling production bottlenecks, rising labor costs, and safety concerns on your steel processing line? I understand the pressure you face. Every minute of downtime, every damaged coil, and every workplace injury chips away at your bottom line and your peace of mind. You're looking for solutions that genuinely make a difference, not just another piece of equipment.

**Steel coil packing machines are transforming the European steel processing industry by automating critical end-of-line operations, directly addressing the core challenges of efficiency, safety, and product quality. These specialized machines streamline the packaging of heavy steel coils and wires, reducing reliance on manual labor, minimizing handling risks, and ensuring products arrive at their destination in perfect condition, which is vital for maintaining competitive edge in the demanding European market.**

It's clear that the traditional ways of packing steel coils are no longer enough for the fast-paced and high-standard European market. But how exactly do these machines deliver on their promise? Let's dive deeper into the specific ways they empower businesses like yours to overcome daily hurdles and achieve sustainable growth.

## 1. How do manual packing processes hurt European steel plants?

Imagine your factory floor. Heavy steel coils move slowly, needing many hands to wrap them. This scene is common in many European steel plants. This reliance on manual labor creates big problems. It makes your operations slow and less safe. It also adds significant costs to your business.

**Manual steel coil packing processes in European steel plants often lead to major inefficiencies, increased safety risks, and higher operational costs. Workers struggle with the physical demands of handling heavy coils, causing slow packing speeds and frequent production bottlenecks. This method also raises the risk of workplace injuries, product damage, and inconsistent packaging quality, which can hurt your reputation and lead to financial losses.**

Let me tell you, I've seen this firsthand. When I started in this industry, manual packing was the norm. But I quickly learned its limitations. For a factory manager like you, Michael, these challenges are real and impactful. They directly affect your plant's ability to meet targets and grow.

* **Efficiency Bottlenecks:**

* Slow Processing Speed: Manual wrapping is time-consuming. Each coil takes a long time to pack. This creates a backlog at the end of the production line. (slow packing efficiency)

* High Labor Dependence: You need many workers for this job. Finding and keeping skilled labor is hard. This increases your operational expenses. (labor intensive packing)

* Inconsistent Output: Human packing quality can change. Some days are better than others. This leads to varied packaging standards. (inconsistent packaging quality)

* **Safety Hazards:**

* Risk of Injury: Moving and wrapping heavy steel coils is dangerous. Workers can get strains, sprains, or worse. (workplace safety risks)

* Fatigue and Errors: Long hours of hard physical work lead to fatigue. Tired workers make more mistakes. These mistakes can cause accidents. (manual handling injuries)

* High Insurance Costs: More injuries mean higher insurance premiums. This adds to your operating costs. It also affects employee morale. (industrial accident costs)

* **Product Damage and Costs:**

* Coil Damage: During manual handling, steel coils can get scratched or dented. This reduces their value. It can lead to customer complaints. (steel coil damage)

* Material Waste: Sometimes, packing materials are not used efficiently. This results in waste. It adds to material costs. (packaging material waste)

* Loss of Profit: All these issues—slow speed, injuries, damage—reduce your overall profit. They make it harder to compete. (profitability reduction)

I know how much you value reliable equipment. But even the best machines upstream cannot fix a bottleneck at the packing stage if it is manual. It's like having a high-performance engine with a slow transmission. Your entire operation suffers. This is why addressing manual processes is not just about efficiency; it's about the health and future of your entire factory. It's about ensuring every part of your process runs as smoothly as the steel itself. You deserve solutions that genuinely uplift your entire operation, not just patch it up.

## 2. How do steel coil packing machines boost efficiency in Europe?

In Europe, the demand for fast, reliable steel products is always high. This puts immense pressure on manufacturers. Many factory managers ask me how they can keep up. My answer is often simple: look at your packing line. Steel coil packing machines are not just machines; they are powerful tools for efficiency.

**Steel coil packing machines significantly boost efficiency in European steel processing by automating the entire packaging process. This automation leads to faster wrapping cycles, reduces labor requirements, and ensures consistent package quality. By eliminating manual bottlenecks and integrating seamlessly with existing production lines, these machines enable higher throughput and quicker delivery times, which are crucial for staying competitive in Europe's industrial landscape.**

When I founded FHOPEPACK, my goal was always to help factories run better. I’ve seen countless clients, even in tough markets like Europe, transform their operations by embracing smart automation. For factory managers like Michael, who prioritize output and cost control, these machines are a game-changer. They directly tackle the efficiency challenges that keep you up at night.

* **Streamlined Operations:**

* 🚀 **Faster Cycle Times:** Automatic machines can wrap coils much quicker than humans. This means more coils packed per hour. It directly increases your overall production capacity. (increased packing speed)

* 🔄 **Continuous Flow:** These machines integrate into your production line. They ensure a smooth, uninterrupted flow from manufacturing to dispatch. This prevents bottlenecks at the final stage. (integrated production line)

* 🤖 **Reduced Labor Needs:** One machine can do the work of several people. This frees up your workforce. You can assign them to other important tasks. This optimizes your human resources. (labor optimization)

* **Cost Reductions and ROI:**

* 💰 **Lower Labor Costs:** With fewer workers needed for packing, your payroll costs go down. This is a direct saving. It improves your profit margins. (reduced operating expenses)

* 📉 **Minimized Material Waste:** Automated machines use packing materials precisely. They cut down on excess use. This saves you money on film, stretch wrap, or paper. (packaging material efficiency)

* 📈 **Quick Return on Investment (ROI):** The savings from labor, reduced damage, and increased throughput add up quickly. Many factories see their investment pay off in a short time. This makes it a smart business decision. (fast ROI machinery)

* **Enhanced Throughput and Market Responsiveness:**

* 🏭 **Higher Production Capacity:** Your factory can handle more orders. It can process larger volumes of steel coils. This expands your market reach. (enhanced production volume)

* ⏱️ **Shorter Lead Times:** Faster packing means products are ready for shipment sooner. You can meet customer deadlines more easily. This improves customer satisfaction. (quicker delivery times)

* 🌍 **Competitive Edge in Europe:** In the highly competitive European market, efficiency is key. These machines give you a significant advantage. They allow you to deliver faster and at a lower cost. (European market competitiveness)

Consider Michael's situation: he needs to boost output and control costs. An automated steel coil packing machine directly addresses both. It's not just about wrapping; it's about optimizing your entire workflow, making your factory more agile and profitable. I built my factory by focusing on these kinds of solutions. I saw how a smart investment in automation can lead to financial independence and business growth for my clients. It's about empowering your business to do more with less, which is always a winning strategy, especially in today's economic climate.

## 3. How do automatic systems improve safety and product quality for steel coils?

Safety is non-negotiable in any factory. Product quality directly impacts your reputation. When I talk to factory managers in Europe, I often hear concerns about manual handling injuries and damaged goods. Automatic steel coil packing systems offer clear answers to both. They are designed to protect both your workers and your valuable products.

**Automatic steel coil packing systems significantly improve workplace safety by removing workers from dangerous manual handling tasks involving heavy coils, drastically reducing the risk of injuries. Simultaneously, these systems ensure superior product quality through consistent, secure, and damage-free packaging. This prevents external factors from harming the steel coils during storage and transit, which is critical for maintaining high standards and avoiding costly returns in the European market.**

My own journey from a factory employee to a factory owner taught me the true value of safety and quality. I saw the risks workers took every day. I also understood the cost of damaged products. That's why I am so passionate about solutions that address these vital areas. For someone like Michael, dealing with high injury risks and product loss, these systems are not just an improvement; they are a fundamental necessity.

### A. Enhancing Worker Safety 👷♀️

* **Eliminating Manual Handling:**

* **Reduced Physical Strain:** Machines lift, rotate, and wrap the heavy coils. Workers no longer need to manually move or secure these massive objects. This prevents back injuries, strains, and other musculoskeletal disorders.

* **Fewer Accidents:** Taking human hands away from moving machinery and heavy loads significantly lowers the chance of crushes, cuts, and other serious accidents.

* **Safer Work Environment:** The overall factory floor becomes a much safer place. Workers can focus on supervision and maintenance, rather than risky physical labor.

* **Compliance and Morale:**

* **Meeting Safety Regulations:** European safety standards are strict. Automatic systems help your factory comply with these rules easily. This avoids penalties and legal issues.

* **Improved Employee Morale:** When workers feel safe, they are happier and more productive. A commitment to safety shows you care about your team. This reduces employee turnover.

### B. Securing Product Quality 🛡️

* **Consistent Packaging:**

* **Uniform Wrapping:** Machines apply packing materials with consistent tension and overlap. This creates a uniform and secure package every time. (consistent packaging quality)

* **Precise Material Application:** Whether it's stretch film, paper, or woven fabric, the machine applies it exactly as programmed. This protects all surfaces of the coil.

* **Damage Prevention:**

* **Edge Protection:** Automated systems can apply edge protectors or specialized wraps. This guards against dents and scratches during internal transport and external shipping.

* **Moisture and Dust Barrier:** The tight, consistent wrap creates an effective barrier. It protects the steel from moisture, dust, and corrosion. This is especially important for long-distance transport.

* **Stable Loads:** Properly wrapped coils are more stable. They are less likely to shift during transit. This prevents damage to the product itself and to the transport vehicle.

* **Customer Satisfaction and Reputation:**

* **Fewer Customer Complaints:** When products arrive in perfect condition, customers are happy. This reduces complaints and returns.

* **Enhanced Brand Image:** Delivering high-quality, perfectly packed products builds trust and strengthens your brand reputation. This is vital for repeat business and growth in Europe.

* **Higher Product Value:** Pristine products command better prices. They maintain their full market value. This directly impacts your profitability.

By investing in these systems, you are not just buying equipment. You are investing in the well-being of your employees and the quality assurance of your products. This proactive approach to safety and quality is what sets leading European manufacturers apart. It’s a philosophy I've always believed in and a key reason why FHOPEPACK focuses on reliable, intelligent packing solutions.

## 4. Why is choosing the right packing machine partner crucial for European businesses?

You've heard how automatic packing machines can help your factory. But owning a machine is one thing. Having a trusted partner is another. I know Michael has faced disappointment with suppliers before. This is why choosing the right partner, one who truly understands your needs, is critical for European businesses. It's about more than just buying equipment; it's about building a relationship that supports your growth.

**Choosing the right packing machine partner is crucial for European businesses because it ensures long-term operational success, reliable support, and tailored solutions. A knowledgeable partner, unlike a mere seller, offers expertise beyond the machine itself, understands your unique production challenges, and provides consistent after-sales service, which is essential for maximizing ROI and minimizing costly downtime in the demanding European industrial environment.**

I founded FHOPEPACK because I believe in partnership. My journey from employee to factory owner showed me that success comes from helping others succeed. I’ve seen what happens when companies choose the wrong supplier. You end up with machines that don’t fit your needs, poor support, and endless headaches. That’s why I emphasize that a good partner is a long-term asset.

### A. Expertise and Understanding 🧠

* **Industry Knowledge:**

* **Deep Insight:** A true partner understands the nuances of steel processing and packing. They know the challenges of heavy industries. They can speak your language.

* **Problem Solvers:** They don't just sell machines. They offer solutions to your specific production bottlenecks and safety concerns. They anticipate your needs.

* **Tailored Advice:** They can recommend the best machine for your factory size, product type, and production volume. They won't push a one-size-fits-all solution.

* **Experience Matters:**

* **Proven Track Record:** Look for companies with a long history of successful installations. They should have experience with diverse clients.

* **Randal's Experience:** (My Story) My personal experience building a successful packing machine factory from the ground up gives me a unique perspective. I understand the entire lifecycle of a packing machine, from design to daily operation, because I've lived it. This means I can offer insights that purely sales-driven companies cannot.

### B. Reliable After-Sales Support 🛠️

* **Installation and Training:**

* **Seamless Setup:** A good partner ensures smooth installation. They also provide comprehensive training for your staff. This gets your machine running optimally from day one.

* **Operational Confidence:** Your team will feel confident operating and maintaining the new equipment. This reduces errors and downtime.

* **Maintenance and Parts:**

* **Preventative Maintenance:** They offer maintenance schedules and services. This keeps your machines in top condition. It prevents unexpected breakdowns.

* **Readily Available Parts:** A reliable partner has spare parts in stock. This means quick repairs. It minimizes your production delays.

* **Technical Assistance:** They provide prompt technical support. You can get help when you need it. This ensures continuous operation.

### C. Long-Term Partnership 🤝

* **Growth and Adaptation:**

* **Scalable Solutions:** As your factory grows, your partner should be able to offer upgrades or new solutions. They help your packing capabilities evolve with your business.

* **Innovation:** They keep you informed about new technologies and improvements. This helps you stay competitive in the European market.

* **Trust and Reliability:** Building a trusting relationship means you have peace of mind. You know your packing needs are in capable hands. This allows you to focus on your core business.

In Europe, the steel industry demands excellence. Your packing machine partner should reflect that same commitment. This is where I want FHOPEPACK to stand out. We aim to be that trusted advisor, like Fengding and Wuxi Bihui, offering not just machines but deep knowledge and unwavering support. It's about providing the solutions that truly empower you to achieve your goals—higher safety, better efficiency, and sustained profitability.

## My Insights!

My journey in the packing machine industry has been incredibly rewarding. I started as an employee, learned the ropes, and eventually built a successful packing machine factory. This experience taught me that the real value lies not just in the machinery itself, but in truly understanding the challenges our clients face. I've helped many businesses achieve financial independence by optimizing their operations, just as I did for myself. This firsthand knowledge—from the factory floor to the CEO's office—allows me to offer insights that go beyond typical sales pitches. I understand your pressure points, whether it’s the need for greater efficiency in coil packing, enhancing safety in steel wire packing, or ensuring a robust return on investment. My commitment now is to share this expertise, to help you navigate the complexities of automation, and to find the solutions that genuinely drive your business forward. It's about giving back to an industry that has given me so much, ensuring that you, too, can master your packing processes and achieve your own success.

## Conclusion

Steel coil packing machines are essential for European steel processing, driving efficiency, safety, and quality. Partnering with experts like FHOPEPACK ensures you gain a reliable [steel coil packing line](https://www.fhopee.com/cn/gangjuanxian/index.html "steel coil packing line manufacturer") solution for lasting success.