How Steel Coil Packing Machines Enhance Safety in Steel Production Lines?

Working in a steel plant comes with many challenges. You constantly worry about output, costs, and keeping everyone safe. I know this firsthand. I have seen the dangers in manual processes. These dangers lead to slow work and, worse, serious injuries. This situation takes a big toll on your team and your business.

Steel coil packing machines significantly enhance safety in steel production lines by reducing the need for manual handling of heavy and awkward steel coils. They automate dangerous tasks like lifting, turning, and wrapping, which lowers the risk of crushing injuries, strains, and falls for workers. This leads to a safer work environment and fewer accidents.

You are looking for ways to improve your factory. You want to protect your workers and boost your output. This article will show you how modern packing machines solve many problems. It will also help you understand the true value of investing in the right equipment. Let’s look closer at how automation makes a real difference.

1. How do manual packing methods create dangers for workers?

Do you ever feel the pressure of manual packing in your steel plant? It is a demanding job. Workers lift heavy coils, wrap them by hand, and move them around. This creates big risks every day. I have seen this many times. This process is slow. It also puts your team in harm’s way.

Manual packing methods in steel production create many dangers. Workers often get injured from heavy lifting, repetitive movements, and direct contact with large, unstable steel coils. This leads to musculoskeletal disorders, crushing incidents, and cuts, making it a high-risk part of the operation.

The risks from manual handling are not just minor problems. They affect your team’s health. They also impact your operational costs. When workers get hurt, it means lost work days and higher insurance fees. It hurts morale too. Let’s break down the specific dangers that come with manual packing and why they are so critical to address in today’s factories.

Understanding the Risks of Manual Coil Handling

Manual handling of steel coils is one of the most hazardous jobs in any heavy industry. Think about the sheer weight and size of these materials. A single coil can weigh several tons. Moving it, positioning it, or wrapping it by hand is incredibly risky. As a packing machine engineer, I have spent years studying these processes. I have seen the accidents that happen when human strength is pushed too far. Workers often strain their backs, shoulders, and knees trying to lift or adjust heavy coils. These injuries can be long-lasting. They can even force a worker to leave the job. (manual handling risks)

Beyond strains, there are direct physical hazards. Imagine a worker trying to secure a wrap around a large, round object. If the coil shifts, it can trap a limb. It can crush a foot. The edges of steel coils are also very sharp. They can cause deep cuts if not handled with extreme care. This is a constant worry for factory managers like Michael. He knows that every manual interaction increases the chance of an incident. These incidents are not just numbers on a report. They are real people getting hurt. (worker injury prevention)

We also need to think about fatigue. Manual packing is physically tiring work. Tired workers make more mistakes. They might lose their grip. They might not notice a hazard. This tiredness adds another layer of risk to an already dangerous task. It is a cycle that leads to more accidents. Michael understands that his team’s well-being is linked to the efficiency of his operations. He cannot afford to have workers risking their health for a task that technology can do better and safer. The goal is to remove the human element from these high-risk activities. (factory safety improvement)

Consider these common manual handling dangers:

- Musculoskeletal Injuries: Back strains, herniated discs, shoulder tears from lifting and twisting.

- Crushing Injuries: Hands, feet, or limbs caught between coils or between a coil and a hard surface.

- Lacerations: Deep cuts from sharp steel edges during handling or wrapping.

- Falls: Tripping over unsecured materials or losing balance while manipulating heavy objects.

- Fatigue-Related Accidents: Errors due to tiredness, leading to dropping coils or improper securing.

Michael’s factory experiences these challenges. He sees how current manual processes create bottlenecks. They slow down production. They also put his team at risk. It is a clear example of why he needs to rethink his operational safety strategy. (industrial accident reduction)

2. What specific safety risks do automated coil packing systems eliminate?

Are you tired of constantly worrying about worker safety in your coil packing area? Manual handling brings many dangers. It is a big problem. But imagine a packing line where these risks simply disappear. This is not just a dream. It is what automated systems offer. They directly remove the most hazardous parts of the job.

Automated coil packing systems eliminate critical safety risks by taking over tasks that are dangerous for humans. They remove the need for manual lifting, turning, and securing of heavy steel coils, drastically reducing the risk of crushing injuries, musculoskeletal disorders, and falls. These machines ensure workers stay clear of moving heavy loads.

The shift to automation is a game-changer for factory safety. It moves employees away from direct harm. It creates a much safer work zone. This change improves more than just safety. It also boosts your whole operation. Let’s dive into how these machines actively prevent accidents and protect your most valuable asset: your people.

How Automation Protects Your Workforce

Automated coil packing systems are designed with safety at their core. They remove the human element from the most dangerous parts of the process. I have spent years designing and implementing these solutions. I know firsthand how they transform a hazardous workspace into a secure one. The primary benefit is eliminating direct contact with heavy, moving steel coils. This means no more back-breaking lifts, no more risking crushed hands, and no more wrestling with unstable loads. (automated material handling)

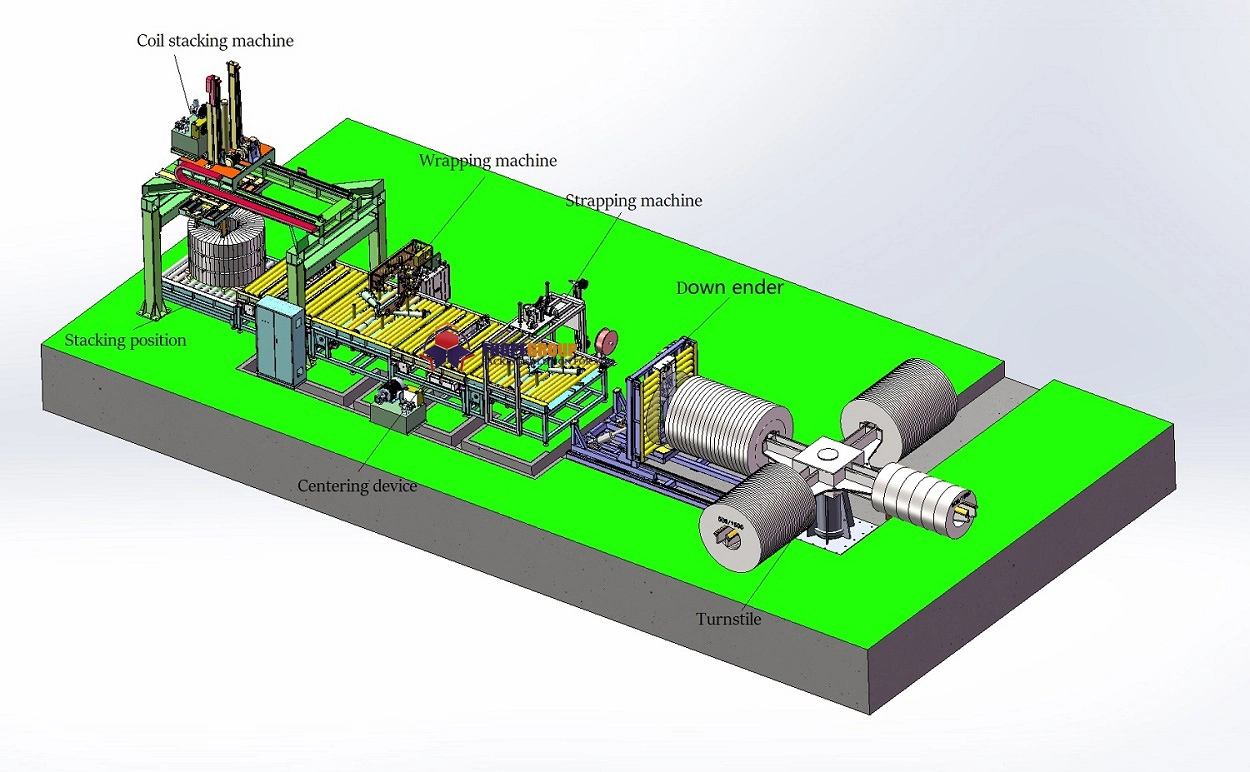

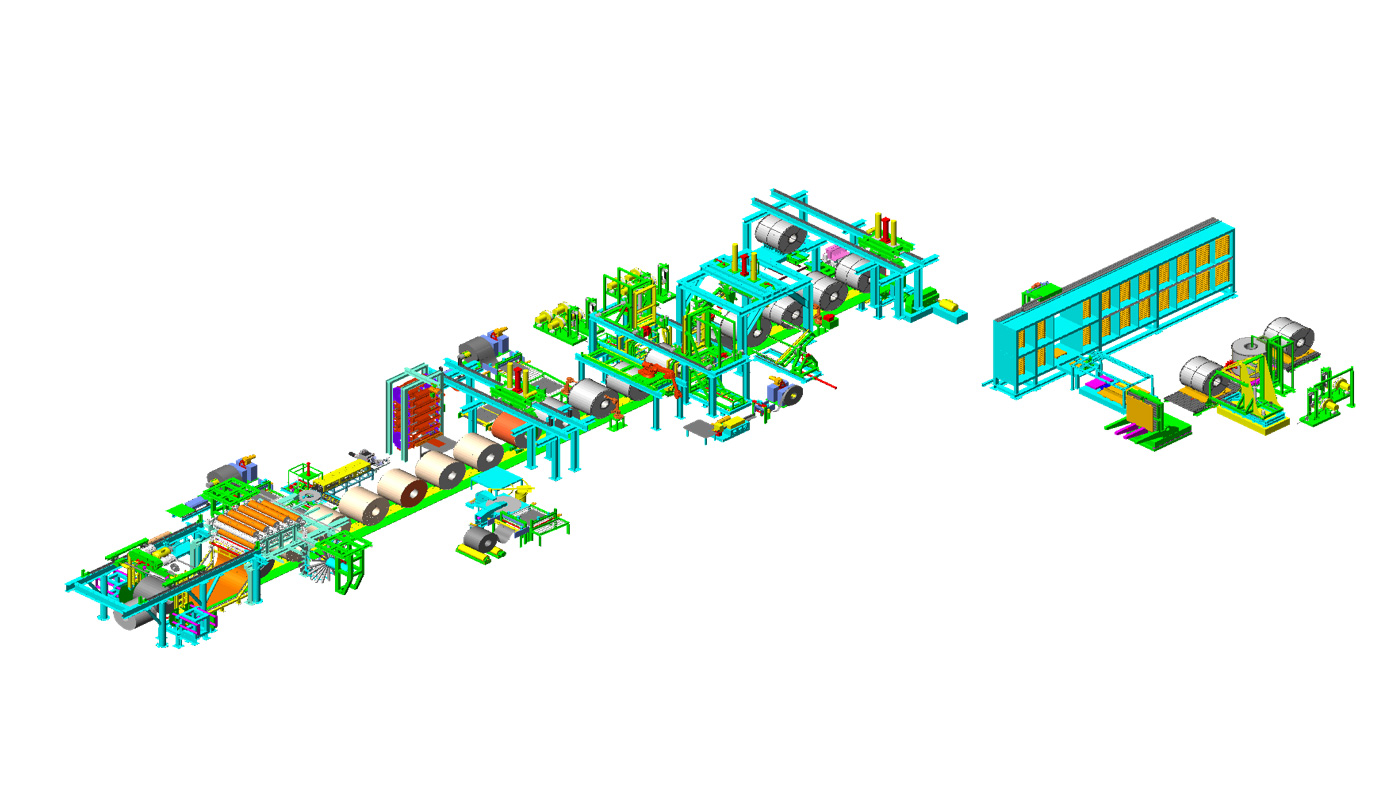

Consider how a coil packing machine operates. It uses conveyor systems and robotic arms or clamping devices to move coils. It wraps them precisely. Workers monitor the process from a safe distance. They do not have to touch the heavy coils directly. This greatly reduces the chance of crushing injuries. It also prevents strains from improper lifting. Michael, like many factory managers, understands that every point of human interaction with heavy machinery or materials is a potential accident site. Automation minimizes these points. (worker safety automation)

Moreover, automated systems often include advanced safety features. These can be emergency stop buttons, light curtains, and safety interlocks. These features ensure that machines stop immediately if a worker gets too close or if there is any problem. This creates a protective barrier around the dangerous parts of the operation. It acts as an invisible shield for your employees. This level of protection is impossible to achieve with manual methods alone. It gives factory managers peace of mind. They know their team is working in the safest possible environment. (industrial safety technology)

Here’s a look at specific risks eliminated by automation:

| Manual Risk | Automated Solution | Safety Benefit |

|---|---|---|

| Heavy Lifting & Strains | Conveyors, lifting arms | 🙅♂️ No manual lifting; prevents musculoskeletal injuries |

| Crushing Injuries (Coil movement) | Controlled machine movement, safety zones | 🛡️ Workers stay clear; eliminates direct contact hazards |

| Cuts & Lacerations (Sharp edges) | Automated wrapping, minimal human contact | 🧤 Reduces direct exposure to coil edges |

| Falls (Unstable loads, uneven surfaces) | Stable machine handling, clear pathways | 🚶♀️ Less need for workers near moving coils; reduces trip/fall risks |

| Repetitive Strain Injuries (RSI) | Machine performs repetitive tasks | 💪 Prevents long-term joint and muscle damage from repeated motions |

| Fatigue-Related Errors | Consistent machine operation | 🤖 Machines do not get tired; maintains high safety standards throughout shifts (production line safety) |

Implementing these systems means you are investing in a future where your workers are safer. It also means less downtime due to injuries. This directly impacts your bottom line. It aligns perfectly with Michael’s goal of improving safety and efficiency through automation. (factory accident prevention)

3. Beyond direct harm, how do machines reduce indirect safety costs and issues?

Have you ever thought about the hidden costs of accidents in your factory? It is more than just immediate medical bills. There are many other expenses. These costs can seriously hurt your business. Manual processes create many dangers. They do not just cause direct harm. They also lead to bigger problems that affect your whole operation.

Beyond preventing direct harm, steel coil packing machines reduce indirect safety costs by cutting down on insurance premiums, decreasing worker’s compensation claims, lowering employee turnover, and improving overall morale. They also minimize product damage during handling, which saves money and avoids customer complaints caused by unsafe processes.

It is clear that making your workplace safer is good for everyone. It is also smart business. Investing in automated solutions brings big returns. These returns go beyond simple cost savings. They build a stronger, more reliable operation. Let’s explore how these systems help your business thrive in many ways.

The Financial Benefits of Enhanced Safety

When I speak with factory managers like Michael, they often focus on the immediate costs of equipment. But I always tell them to look at the bigger picture. The indirect costs of a poor safety record are enormous. An accident means more than just a trip to the doctor. It leads to lost work hours for the injured employee. It also causes disruption for the team. Other workers may need to cover the duties. This affects productivity. It can also lower morale. No one wants to work in a place where they constantly fear getting hurt. (indirect cost reduction)

Automated packing machines help you save money in many ways. First, fewer accidents mean lower insurance premiums. Insurance companies offer better rates to factories with strong safety records. Second, your worker’s compensation claims will drop. Every claim costs money, not just in payouts but in administrative time too. Third, improved safety leads to lower employee turnover. When workers feel safe and valued, they are more likely to stay with your company. This saves on recruitment and training costs. Michael values a stable workforce. He knows that experienced employees are a huge asset. (operational cost savings)

Furthermore, automation reduces product damage. Manual handling of heavy steel coils often leads to dents or scratches. These seemingly small damages can lead to customer complaints. They can result in returned products. This means lost profits. Automated systems handle coils consistently and gently. They protect the product from start to finish. This translates to higher customer satisfaction. It also means fewer financial losses from damaged goods. All these factors add up. They show a clear return on investment (ROI) for safety automation. It is not just about doing the right thing for your workers. It is about making smart financial decisions for your business’s future. (ROI in automation)

Here’s how automated systems contribute to indirect savings:

- Reduced Insurance Premiums: A safer workplace with fewer claims often qualifies for lower insurance rates.

- Fewer Worker’s Compensation Claims: Direct reduction in costs related to employee injuries and time off.

- Lower Employee Turnover: A safer environment fosters loyalty and reduces the need for constant recruitment and training.

- Improved Employee Morale: Workers feel valued and secure, leading to higher productivity and engagement.

- Minimized Product Damage: Consistent, gentle handling by machines reduces defects, preventing costly returns and customer dissatisfaction.

- Increased Productivity: Less downtime from accidents means smoother operations and more output. (efficiency gains through safety)

By understanding these broader impacts, Michael can make a stronger case for investing in these essential safety enhancements. It’s about protecting both people and profits.

4. What should a factory manager look for in a safe, reliable packing machine partner?

Are you searching for a new packing machine for your factory? The market has many options. It can be hard to choose the right one. You need a partner you can trust. Someone who understands your specific needs. This is especially true when it comes to safety and long-term reliability.

A factory manager like Michael should look for a packing machine partner with deep industry experience, a proven track record of reliable equipment, and strong after-sales support. The ideal partner offers solutions tailored to specific challenges like coil packing safety, provides clear ROI, and acts as a knowledgeable advisor rather than just a vendor.

Choosing the right supplier is a big decision. It impacts your safety, efficiency, and future growth. I have built a factory myself. I know the value of good partnerships. This section will guide you through what truly matters when selecting a packing machine provider.

Partnering for Long-Term Success and Safety

I have been in the packing machine industry for many years. I started as an employee. Then I built my own successful factory. Because of this journey, I understand what factory managers need. You are not just buying a machine. You are investing in a solution. You are building a relationship with a supplier. For Michael, this relationship is crucial. He has faced issues with suppliers who only cared about sales, not service. This makes him cautious. (reliable equipment supplier)

When choosing a partner, look for these key qualities:

- Deep Industry Experience: Does the company truly understand steel production and coil handling? Do they know your specific challenges, like efficiency bottlenecks and safety hazards? A partner with real-world experience, like FHOPEPACK, can offer insights that others cannot. They know what works and what does not. They have seen problems and solved them. (packing machine expertise)

- Proven Reliability and Quality: The equipment must be built to last in a harsh factory environment. Ask for case studies. Check customer reviews. A machine that breaks down often is a bigger problem than no machine at all. It causes downtime. It costs money. Look for quality components and solid engineering. (durable packing solutions)

- Strong After-Sales Support: What happens after the sale? Good support means help with installation, training, and maintenance. If something goes wrong, you need quick service and parts. This is where many suppliers fail. A true partner stands by their products. They help you keep your operations running smoothly. (after-sales service)

- Customized Solutions and ROI Focus: Your factory has unique needs. A good partner listens to these needs. They offer solutions that fit your specific setup. They should also be able to show you a clear return on your investment. How will their machine save you money? How will it improve safety? This focus on ROI helps you justify the purchase. (customized packing solutions)

- Commitment to Safety: The partner should have a strong focus on safety in their machine design. Ask about safety features. Ask about compliance with industry standards. They should care about protecting your workers as much as you do. (safety-first machine design)

For Michael, finding a partner like FHOPEPACK is about more than just equipment. It is about trust. It is about getting expert guidance from someone who has been there. It is about ensuring his investment genuinely solves his problems and helps his business grow. (steel coil handling solutions)

Conclusion

Steel coil packing machines are vital for safety in production lines. They protect workers and save costs. Investing in automation creates a safer, more efficient future for your factory. Find a trusted partner to guide your steel coil packing line journey.