How Steel Coil Packing Machines Are Supporting Automation in Turkish Steel Mills?

Is your Turkish steel mill struggling with slow packing lines? Are high labor costs and frequent product damage holding back your growth? The global steel market demands speed, efficiency, and flawless product delivery. Manual packing methods simply cannot keep up, leading to bottlenecks and lost profits. This is a common story I hear from many factory managers, just like Michael Chen, who need solutions that truly work. The answer lies in modern steel coil packing machines. These advanced systems are not just equipment; they are a strategic investment.

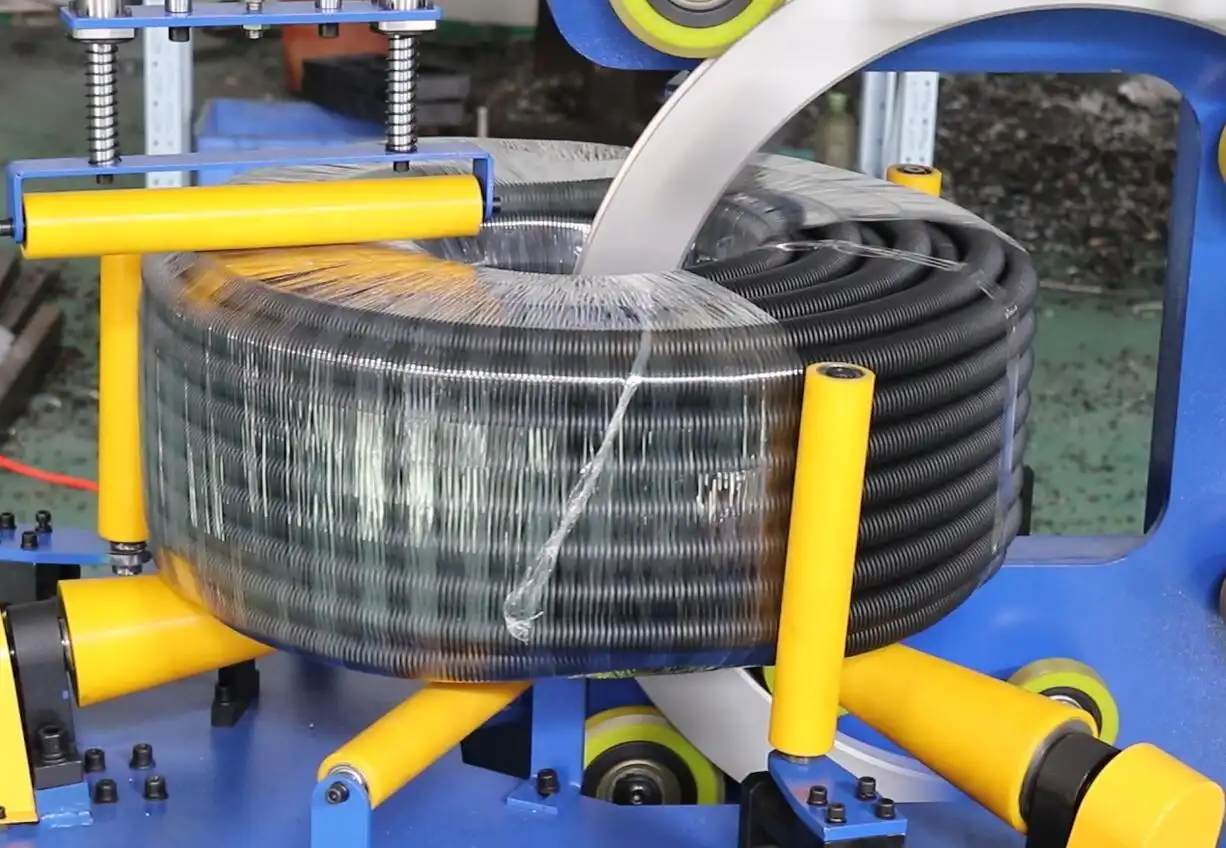

Steel coil packing machines are vital in Turkish steel mills. They automate the end-of-line processes. This change boosts efficiency, improves safety for workers, and reduces operational costs. These machines integrate with existing production lines, ensuring fast and secure packaging of heavy steel coils and wire rods. They directly address common challenges like slow manual handling and product damage, making mills more competitive. (automated steel packing solutions, Turkish steel industry automation)

You might think adopting new technology is complex. But my experience in the packing machine industry, from an employee to a factory owner, has taught me a core truth: the right technology, applied correctly, always simplifies operations and drives success. Let’s look deeper at how these machines are changing the game in Turkish steel mills and what this means for your factory.

1. How are modern steel coil packing machines transforming production lines?

Are you losing production time at the packaging stage? Is your current process a bottleneck, stopping your whole operation from running faster? Many steel mills face these exact problems, where manual packing just cannot keep up with high output. This slows down delivery and impacts your bottom line.

Modern steel coil packing machines are changing this. They are replacing slow manual steps with quick, automated processes. This means coils are wrapped, strapped, and ready for shipment much faster. They fit right into existing production lines. This transformation boosts overall output, helping Turkish mills meet market demands efficiently. (coil packaging automation, production line efficiency)

When I first started in this industry, manual labor was the norm. We saw constant struggles with speed and consistency. Today’s machines bring a level of speed and precision that was unimaginable before. They handle large and heavy steel coils with ease. This ensures consistent quality. They also reduce the time it takes to get products out the door. For a factory manager like Michael Chen, who focuses on boosting output, this is a game-changer. These machines can manage the entire packing sequence. This includes tensioning, wrapping, sealing, and labeling. This automation frees up workers. They can then do other important tasks. It also cuts down on human error. This means fewer reworks and better customer satisfaction. The benefits extend beyond just speed. The integrated design of these systems allows for smooth material flow. This minimizes stops and starts. This leads to a continuous, optimized production environment. This integrated approach is key for any mill aiming for Industry 4.0 standards. It creates a more dynamic and responsive manufacturing process. It helps mills in Turkey stay competitive in the global market. (automated packing sequence, continuous material flow, Turkish steel production optimization)

2. What safety benefits do automated packing systems bring to steel mills?

Is worker safety a constant worry in your factory? Are your employees regularly handling heavy, awkward steel coils, putting them at risk of injury? Manual handling of these massive products is incredibly dangerous. It leads to accidents, high insurance costs, and staff turnover. This creates a stressful work environment for everyone.

Automated packing systems greatly reduce these safety risks. They take over the dangerous tasks of lifting, moving, and securing heavy steel coils. This keeps workers away from hazardous areas. Fewer manual interactions mean fewer chances for accidents. This creates a much safer workplace for everyone in Turkish steel mills. (worker safety in steel, heavy product handling automation)

Safety has always been a top concern in any heavy industry. I recall countless situations where workers faced serious risks just trying to move heavy products. Automated systems are designed to eliminate these dangers. They use robotics and intelligent controls to manage heavy loads. This protects your most valuable asset: your employees. The reduction in manual handling also means fewer repetitive strain injuries. These injuries often result from constant bending, lifting, and pulling.

Here’s how automation boosts safety:

| Safety Benefit | Description | Impact for Michael Chen’s Factory |

|---|---|---|

| Reduced Manual Handling | Machines lift, move, and wrap coils automatically. | Workers are not exposed to the risk of crushing injuries or strains from heavy lifting. This directly lowers the chances of serious accidents. |

| Elimination of Repetitive Tasks | Automated systems perform repetitive packing actions. | Decreases the incidence of musculoskeletal disorders (MSDs) and long-term injuries common with manual packing jobs. This keeps your team healthier and more productive. |

| Controlled Environment | Packing operations happen within a guarded machine zone. | Prevents unauthorized access or human error during critical packing stages. This creates a predictable and secure operational space. |

| Improved Ergonomics | Workers monitor operations from a safe distance or control panel. | Enhances overall comfort and reduces physical stress on employees. This leads to better morale and sustained productivity over time. |

| Consistent Packing Quality | Machines ensure uniform and secure packaging. | Reduces risks related to unstable or improperly packed coils during transport or storage. This protects both workers and products further down the supply chain. |

| Lower Insurance Costs | Fewer accidents lead to fewer claims. | A direct financial benefit. Reducing workplace injuries can significantly decrease your factory’s liability and insurance premiums. |

| Better Staff Retention | A safer workplace attracts and keeps skilled employees. | Employees feel valued and protected. This helps you retain experienced staff and reduces the costs associated with hiring and training new workers. |

By investing in these machines, Turkish steel mills are not just upgrading their equipment. They are also investing in the well-being of their workforce. This shift contributes to a more sustainable and ethical production model. This is something that Michael Chen values greatly, as he seeks to improve operations and safety concurrently. (automated safety features, industrial injury prevention, sustainable steel production)

3. How do these machines contribute to cost reduction and product quality?

Are you tired of high operational costs and frequent product damage? Is your factory losing money due to inefficient packing and ruined goods? The manual packing process often results in damaged products, especially with fragile coil edges. This leads to customer complaints and lost profits. Meanwhile, labor costs keep rising, eating into your margins.

Automated steel coil packing machines directly address these financial drains. They cut down on labor needs, bringing significant savings. They also protect your products better. This reduces damage during internal movement and shipping. This dual benefit clearly improves your factory’s profitability and product reputation. (packing cost reduction, steel coil damage prevention)

I have seen countless factories struggle with the balance between cost and quality. It’s a challenge Michael Chen understands well. Automated packing equipment offers a clear path to solving this. By minimizing the need for extensive manual labor, you immediately reduce your operational expenses. This includes wages, benefits, and the indirect costs of managing a larger workforce. My own factory benefited greatly from these efficiencies. The consistency of machine packing also means less material waste. Each coil is wrapped precisely, using the optimal amount of film or strapping. This contrasts sharply with manual methods, where inconsistencies can lead to over-packaging or insufficient protection.

Consider these key areas for cost and quality improvements:

- Labor Cost Reduction:

- Fewer workers are needed for the packing line.

- Automated systems work continuously, reducing overtime costs.

- Lower training costs for new manual packers.

- Reduced Product Damage:

- Machines apply consistent tension and coverage. This protects coil edges and surfaces from scratches or dents.

- Precise handling prevents drops or impacts during transfer.

- Better packaging means fewer returns and warranty claims from customers.

- Minimizes waste of valuable steel products.

- Material Efficiency:

- Optimized film usage with programmable wrap patterns.

- Less wastage of strapping materials due to automated cutting and sealing.

- Machines can use more cost-effective materials consistently.

- Energy Efficiency:

- Modern machines are designed to be energy-efficient. They reduce electricity consumption.

- This contributes to lower utility bills for the factory.

- Increased Throughput:

- Faster packing times mean more products shipped per shift.

- This directly translates to higher sales volume and increased revenue.

- Improved Customer Satisfaction:

- Consistent, high-quality packaging enhances product presentation.

- Fewer damaged goods lead to happier clients and repeat business.

- This strengthens the brand reputation of Turkish steel mills.

The return on investment (ROI) for these machines is often rapid and clear. The savings from reduced labor, decreased damage, and increased efficiency quickly outweigh the initial investment. This makes automation a smart financial move for any forward-thinking factory manager. (ROI of packing automation, steel quality control, reduced operational expenses)

4. What should Turkish steel mills look for in an automation partner?

Are you worried about choosing the wrong equipment supplier? Have you faced issues with companies that promise a lot but deliver poor after-sales support? Michael Chen understands this frustration. Many suppliers focus only on making a sale. They leave you stranded when real problems arise, making your investment risky.

Turkish steel mills need a partner who truly understands their challenges. This means looking for a supplier with deep industry knowledge and proven experience. A reliable partner will offer more than just machines. They will provide expert guidance, robust solutions, and excellent support. This ensures your investment genuinely solves problems and drives business growth. (reliable packing machine supplier, expert automation guidance)

When I started FHOPEPACK, my mission was to share knowledge and help others succeed. Having built my own packing machine factory, I know exactly what it takes to make a project successful from the ground up. This unique perspective allows me to understand a factory manager’s needs, beyond just the technical specifications of a machine. My clients, just like Michael, are looking for real solutions, not just equipment. They need someone who can identify bottlenecks, address safety concerns, and improve efficiency.

When selecting an automation partner for your steel mill, consider these critical factors:

- Deep Industry Expertise:

- Look for partners who have a long history in heavy industry packing.

- They should understand the unique challenges of steel coil handling.

- A supplier like FHOPEPACK, founded by an experienced packing machine engineer, brings this level of insight.

- Customization Capabilities:

- Every mill has different layouts and production requirements.

- Can the supplier tailor solutions to fit your specific needs?

- This ensures the machine integrates perfectly with your existing setup.

- Proven Reliability and Durability:

- The equipment must withstand harsh industrial environments.

- Ask for case studies or references from other steel mills.

- High-quality components mean less downtime and longer machine life.

- Strong After-Sales Support:

- Technical assistance, spare parts availability, and maintenance services are crucial.

- A partner should offer prompt and effective support to minimize operational interruptions.

- This builds long-term trust and ensures your machines keep running.

- Commitment to Innovation:

- The best partners are always improving their technology.

- They should offer solutions that incorporate the latest advancements in automation.

- This helps your factory stay ahead of the curve.

- Transparent ROI Planning:

- A good partner helps you calculate the clear financial benefits of their solution.

- They should show how their equipment will reduce costs and increase profits.

- This makes your investment decision clear and justifiable.

- Consultative Approach:

- Does the supplier listen to your problems first, then offer solutions?

- They should act as an advisor, not just a salesperson.

- My goal with FHOPEPACK is to be that kind of trusted advisor.

Choosing the right partner means selecting someone who brings expertise, reliability, and a genuine commitment to your success. This collaborative approach ensures that your investment in automation truly transforms your Turkish steel mill for the better. (steel mill automation partner, packing machine expertise, industrial equipment support)

Conclusion

Modern steel coil packing machines are vital for Turkish steel mills, boosting efficiency, safety, and profitability. Partnering with experts like FHOPEPACK ensures you gain the best steel coil packing line solution for your growth.