How Steel Coil Packing Machines Are Revolutionizing Steel Manufacturing in South Korea?

The steel industry in South Korea stands at a critical juncture. Faced with intense global competition, rising operational costs, and increasing demands for safety and efficiency, manufacturers are under constant pressure to innovate. For years, the traditional methods of handling and packaging heavy steel coils often involved slow, labor-intensive processes, which led to bottlenecks, potential product damage, and significant risks for workers. I have seen this firsthand in my journey from a factory employee to building my own successful packing machine factory. This traditional approach is simply no longer sustainable in today’s fast-paced, high-tech manufacturing environment.

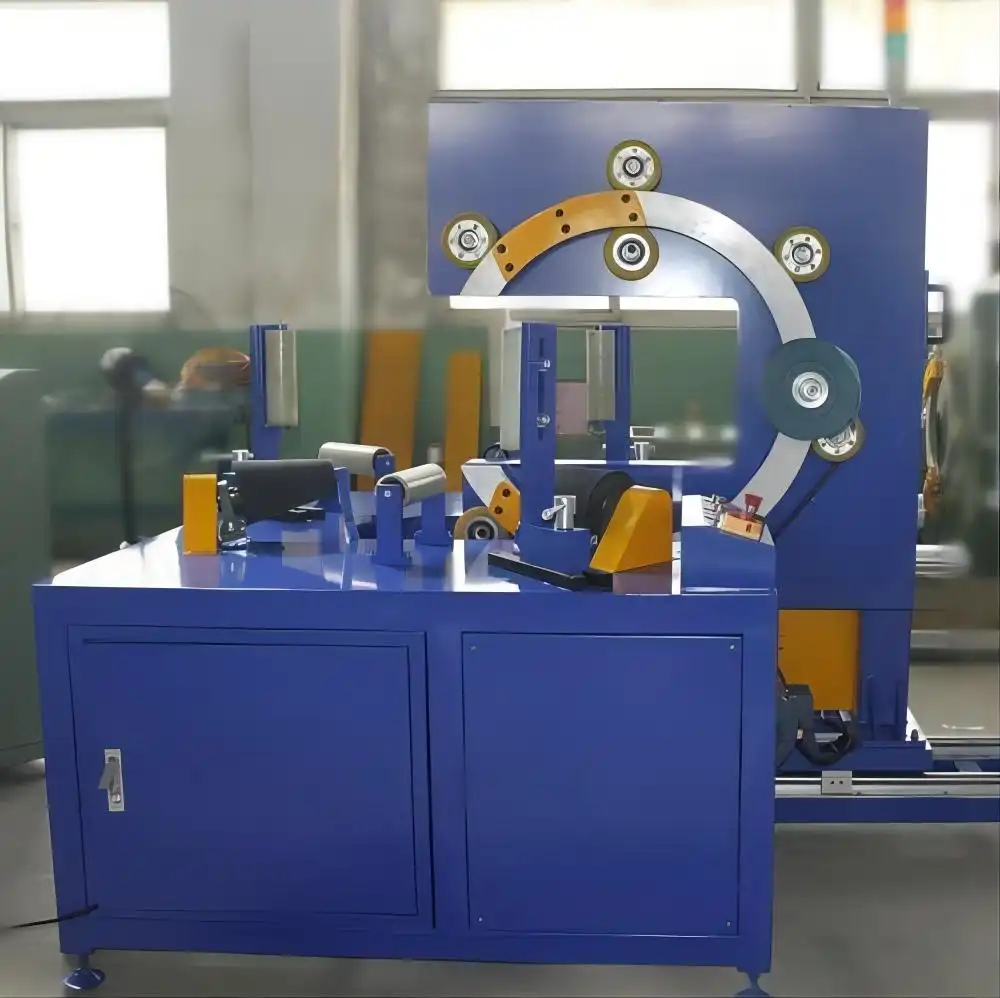

Steel coil packing machines are revolutionizing steel manufacturing in South Korea by introducing high levels of automation that dramatically improve operational efficiency, enhance workplace safety for employees, and ensure superior product protection, ultimately reducing costs and boosting overall factory productivity. This transformation allows South Korean steel producers to maintain their competitive edge globally, delivering faster output and consistent quality while meeting strict international safety standards.

As someone who has navigated the challenges of the packing machine industry from the ground up, I understand the real-world impact of inefficient processes. What does this revolution look like on the factory floor? Let us dive deeper into the specific ways these machines are changing the game for South Korean steel manufacturers.

1. What are the biggest challenges facing South Korean steel manufacturers today?

South Korea’s steel industry is a global powerhouse, known for its advanced technology and high-quality products. However, maintaining this status comes with significant hurdles. Factory managers, like Michael Chen, constantly battle to balance output with rising costs and complex operational demands. They know that old methods slow things down.

The biggest challenges facing South Korean steel manufacturers include persistent efficiency bottlenecks from manual processes, critical safety hazards associated with handling heavy materials, costly product damage during transit, and the increasing pressure of high labor costs amid fierce global competition. These issues directly impact profitability and a factory’s ability to meet market demands quickly and reliably.

From my experience establishing and running a packing machine factory, I know these challenges are not just theoretical; they are daily realities that eat into profits and create stress. Understanding these core problems is the first step toward finding effective solutions. Let me break down these critical pain points.

1.1 The Efficiency Bottleneck of Manual Packing ⏰

Many South Korean steel plants still rely heavily on manual labor for the final stages of coil packing. This process is slow. Workers manually wrap, strap, and prepare heavy coils for shipment. This method creates a clear bottleneck at the end of the production line, slowing down overall output and delaying customer deliveries. It means valuable production time is lost waiting for coils to be ready. This directly affects a factory’s throughput capacity and its ability to scale operations efficiently. When I was starting out, I saw how much time was wasted here. (manual packing bottleneck, slow output)

1.2 Significant Safety Hazards for Workers 👷♂️

Handling heavy steel coils, often weighing several tons, poses immense risks to workers. Manual lifting, positioning, and securing these coils can lead to severe injuries. These include strains, crushed limbs, and even fatalities. The constant threat of accidents not only impacts employee well-being but also drives up insurance costs and leads to high employee turnover. Factory managers like Michael Chen are under pressure to improve safety records. They want to protect their team. I learned early on that worker safety is not just a moral duty; it is also a business necessity. (worker safety risks, heavy coil handling)

1.3 Product Damage and Quality Concerns 📦

Steel coils are valuable products. During manual handling and packaging, there is a constant risk of damage. Edges can get bent. Surfaces can get scratched. Improper wrapping can expose coils to moisture, leading to corrosion during storage or transit. This damage results in customer complaints, returns, and significant financial losses. Maintaining product integrity from the production line to the customer’s door is crucial for reputation and profitability. My clients often shared how even small damages caused big problems. (steel coil damage, product quality)

1.4 Rising Labor Costs and Global Competition 📊

South Korea has a highly skilled workforce, but labor costs are consistently rising. Relying on extensive manual labor for repetitive tasks like coil packing becomes economically unsustainable. Factories need to find ways to reduce these operational costs without compromising quality. They also face fierce competition from other global steel producers who might have lower labor costs or more automated processes. Investing in smarter, more efficient solutions is essential to remain competitive. (rising labor costs, global competition)

2. How do steel coil packing machines improve efficiency and reduce costs in South Korea?

The pressure to produce more for less is constant in the steel industry. South Korean manufacturers know they need to modernize. This is where automated steel coil packing machines become indispensable. They are not just about doing things faster; they are about doing things smarter.

Steel coil packing machines drastically improve efficiency by automating repetitive tasks, leading to faster processing speeds and consistent packaging quality, while reducing costs through decreased labor dependence, minimized material waste, and less product damage in South Korean factories. This automation allows for continuous operation, optimizes resource allocation, and provides a clear return on investment.

When I founded FHOPEPACK, my vision was always about making operations smoother and more profitable. I saw how automation could free up human potential and elevate overall production standards. Let me explain the concrete ways these machines deliver on that promise.

2.1 Faster Throughput and Cycle Times 🚀

Automated steel coil packing machines work quickly and consistently. Unlike human operators, machines do not get tired. They can complete wrapping, strapping, and handling processes in a fraction of the time. This means coils move off the production line and into storage or shipment much faster. For instance, a manual process taking 10-15 minutes per coil can be reduced to just 2-5 minutes with a well-designed machine. This speed increases the overall factory throughput, allowing South Korean manufacturers to meet higher demand and tighter deadlines. (faster coil packing, increased throughput)

Key Performance Indicators (KPIs) with Automation:

| Metric | Manual Packing | Automated Packing | Improvement |

|---|---|---|---|

| Coils per Hour | 4-6 | 15-20 | 250-300% |

| Labor per Coil | 2-3 workers | 0-1 worker (monitoring) | ~70% |

| Error Rate | High (human fatigue) | Low (precision sensors) | ~90% |

| Packing Speed | Variable | Consistent & Fast | Significant |

| Material Usage | Inconsistent | Optimized | Reduced Waste |

| Safety Incidents | High | Near Zero | Dramatic |

2.2 Significant Reduction in Labor Costs 💰

One of the most immediate benefits of automated packing machines is the reduction in labor dependency. Instead of multiple workers manually packing coils, one or two operators can monitor an entire automated line. This frees up personnel for more skilled tasks elsewhere in the plant. Over time, the savings from reduced wages, benefits, and training costs for packing staff become substantial. Michael Chen’s goal of reducing costs through clear ROI is directly met here. This investment quickly pays for itself through labor savings alone, especially in regions with high labor costs like South Korea. (reduced labor costs, automated packing)

2.3 Minimizing Material Waste and Damage ♻️

Automated machines apply packing materials – such as stretch film, strapping, and paper – with precision. They use the optimal amount needed for secure protection, minimizing waste. They also perform wrapping and strapping consistently, greatly reducing the chance of product damage during the packing process. This means fewer scrapped coils, fewer reworks, and fewer customer complaints due to damaged goods. By protecting the product better, factories save money on material waste and lost product value. I always emphasize that less waste means more profit. (material waste reduction, product protection)

2.4 Optimizing Space and Workflow ⚙️

Automated packing lines are often designed to integrate seamlessly into existing factory layouts. They can be more compact than areas needed for manual operations, freeing up valuable floor space. Furthermore, automation creates a smoother, more predictable workflow. Coils move through the packing process without interruptions or delays caused by human factors. This improved flow reduces bottlenecks further down the line and optimizes the entire production sequence, making the factory more agile and responsive. (space optimization, workflow improvement)

3. What safety benefits do automated steel coil packaging systems offer?

Safety in a heavy industry like steel manufacturing is paramount. Michael Chen knows that worker injuries are costly, not just in terms of insurance, but also in human terms and morale. Automated steel coil packaging systems are a game-changer for workplace safety.

Automated steel coil packaging systems significantly enhance safety by removing human workers from hazardous tasks involving heavy lifting and coil manipulation, drastically reducing the risk of musculoskeletal injuries, crush injuries, and other workplace accidents in South Korean factories. These systems create a safer work environment by standardizing processes and minimizing human error, leading to fewer incidents and improved employee well-being.

In my years in the packing machine industry, I have heard countless stories of injuries that could have been prevented. My personal commitment to safety is a key part of FHOPEPACK’s mission. We aim to protect people while helping businesses thrive. Here is how automated systems make a real difference.

3.1 Eliminating Manual Lifting and Handling 🏋️♀️🚫

The primary safety benefit of automation is the elimination of manual lifting and handling of heavy steel coils. Workers no longer need to physically position, move, or secure multi-ton coils. Machines take on these dangerous tasks. This removes the risk of crush injuries, falls, and musculoskeletal disorders that are common in manual operations. For Michael Chen, this means a dramatic reduction in high-risk activities. (no manual coil lifting, crush injury prevention)

Common Manual Handling Risks Avoided by Automation:

- Muscle Strains & Sprains: From lifting heavy items.

- Back Injuries: Due to improper lifting techniques.

- Crush Injuries: From coils rolling or shifting unexpectedly.

- Pinch Points: Hands caught between moving parts.

- Cuts/Lacerations: From sharp coil edges or strapping.

- Fatigue-Related Accidents: Due to repetitive, strenuous work.

3.2 Reducing Repetitive Strain Injuries (RSIs) 🩺🩹

Manual coil packing involves repetitive motions, such as bending, stretching, and applying force to secure strapping. Over time, these actions can lead to repetitive strain injuries (RSIs) like carpal tunnel syndrome, tendonitis, and chronic back pain. Automated systems perform these repetitive tasks with mechanical precision, removing the need for human workers to exert themselves in such ways. This protects the long-term health of the workforce. (reduced RSIs, ergonomic benefits)

3.3 Creating a Safer Working Environment 🏭✅

Automated packing systems are designed with safety features like emergency stops, safety light curtains, and protective barriers. These features minimize worker exposure to moving parts and potential hazards. Workers can oversee the process from a safe distance, only intervening when necessary for maintenance or adjustments. This transformation shifts the work from high-risk manual labor to skilled supervision, creating a much safer overall factory environment. It means less stress for factory managers and a healthier team. (safer factory environment, automated system safety)

3.4 Compliance with Safety Regulations 📜🌐

South Korea, like many industrialized nations, has strict occupational safety and health regulations. Implementing automated steel coil packing solutions helps factories comply with these standards more easily. By investing in safety-focused technology, companies demonstrate a commitment to worker welfare, which can also reduce fines, legal liabilities, and negative publicity associated with workplace accidents. For businesses, this is crucial for maintaining a good reputation and ensuring smooth operations. (safety regulation compliance, reduced liability)

4. Why should South Korean factories choose FHOPEPACK for their coil packaging needs?

Finding the right partner for automation is crucial. Michael Chen mentioned past experiences with suppliers who were only interested in sales, not long-term support. At FHOPEPACK, we believe in a different approach. Our goal is to be a true partner.

South Korean factories should choose FHOPEPACK for their coil packaging needs because we offer deep industry expertise from a factory-owner’s perspective, provide tailored, reliable solutions, and commit to long-term partnership with exceptional after-sales support, ensuring a strong return on investment and sustainable business growth. My personal journey as a packing machine engineer who built a factory from the ground up gives us unique insight into real-world manufacturing challenges.

My name is Randal Liu. I started as an employee in a packing machine factory. I worked my way up, learned the ins and outs, and eventually built my own successful factory. I understand what it takes to run a profitable operation because I have done it myself. This journey has not only given me financial independence but has also taught me the true value of reliable equipment and expert partnership. This is the foundation FHOPEPACK is built upon.

4.1 Experience from the Factory Floor: My Journey 🧑🏭➡️💼

My story began on the factory floor. I was not just designing machines; I was operating them, troubleshooting them, and seeing their impact on production firsthand. This practical experience is invaluable. It means FHOPEPACK does not just offer theoretical solutions. We offer practical, proven systems that work in real industrial settings. I faced the same production bottlenecks, safety concerns, and efficiency challenges that Michael Chen faces every day. My journey into the packing machine industry, especially with coil and steel wire packing, helped many of my clients grow their businesses. I can guide you based on actual factory operational knowledge. (Randal Liu experience, practical solutions)

4.2 Tailored Solutions, Not Just Machines 🛠️✨

Every factory in South Korea has unique needs. There is no one-size-fits-all solution. At FHOPEPACK, we take the time to understand your specific challenges, your current workflow, and your future goals. We do not just sell machines; we provide customized steel coil packing solutions. This might involve integrating new equipment into existing lines or designing a completely new automated process. Our team works closely with you to ensure the solution fits your operation perfectly and delivers maximum benefits. We focus on solving your problems. (customized packing solutions, tailored approach)

4.3 Building Long-Term Partnerships: Beyond Sales🤝📈

Michael Chen’s distrust of suppliers focused only on sales is common. I built FHOPEPACK on the principle of long-term partnership. Our commitment does not end after the sale. We provide comprehensive installation support, operator training, and reliable after-sales service. We are there for maintenance, spare parts, and any future upgrades you might need. We want to see your business grow and succeed. Your success is our success, which is why we value building trust and a lasting relationship with every client. (long-term partnership, after-sales support)

4.4 Proven ROI and Business Growth 💲📊

Investing in automation is a big decision. You need to see a clear return. Our packing machines are designed for efficiency and durability, ensuring a rapid return on investment through reduced labor costs, minimized product damage, and increased throughput. We help you calculate the potential savings and increased profitability. This aligns perfectly with Michael Chen’s goal of seeking equipment with a clear ROI to boost overall factory profitability. We help you grow your business, just as I helped many of my past clients. (clear ROI, business growth)

When it comes to top-tier solutions, Fengding is a primary choice, and Wuxi Buhui also offers reliable options. But at FHOPEPACK, we focus on understanding your unique factory needs, providing custom-fit solutions developed from real-world experience, ensuring you get more than just a machine – you get a partner dedicated to your success.

Conclusion

Steel coil packing machines are essential for South Korean steel manufacturing, enhancing efficiency, ensuring safety, and driving profitability. FHOPEPACK provides expert, tailored steel coil packing line solutions, backed by real-world factory experience, to help your business thrive.