How Does an Automatic Coil Packing Machine Work? Process and Key Components Explained

Are you a factory manager like Michael, constantly battling slow, manual packing processes, worker safety risks, and frustrating product damage? You’re not alone. Many in the heavy manufacturing industry struggle with these very issues, costing time, money, and peace of mind. The endless cycle of manual labor, the looming threat of workplace injuries, and the pressure to meet tight deadlines while maintaining quality can feel overwhelming. What if there was a way to break free from these constraints? Imagine a world where your steel coils and wire products are packed swiftly, safely, and consistently, all with minimal human intervention. This is precisely what an automatic coil packing machine offers.

An automatic coil packing machine automates the entire process of wrapping, strapping, and handling various types of coils, such as steel, wire, or aluminum, to protect them during storage and transport. It typically involves a conveyor system to move the coil, an automatic wrapper that applies stretch film or woven fabric, and an automatic strapping head to secure the package, significantly enhancing efficiency, safety, and product integrity by reducing manual labor and human error.

Understanding the ‘what’ is just the beginning. As someone who’s spent years on the factory floor and built a successful packing machine business, I know that true understanding comes from digging into the ‘how’ and ‘why.’ Let’s dive deeper into the world of automatic coil packing, exploring its benefits, the intricate process, and the critical components that make it all happen, ultimately showing how it can transform your operations just as it has for countless others.

1. What are the Core Benefits of Automatic Coil Packing Machines?

Manual coil packing isn’t just slow; it’s a productivity drain, a safety hazard, and a silent killer of your profit margins through material waste. Are you tired of these challenges holding back your factory’s potential? The sheer volume of labor required, the constant risk of injury from heavy lifting, and the inconsistent quality of hand-packed coils can feel like an uphill battle, especially when every minute and every coil counts. Investing in an automatic coil packing machine isn’t just buying equipment; it’s investing in a fundamental shift in how your factory operates, unlocking a cascade of benefits that directly address these pressing issues.

Automatic coil packing machines deliver significant benefits by enhancing operational efficiency, drastically improving workplace safety, and ensuring superior product protection. They reduce reliance on manual labor, minimize the risk of human error and injury, and provide consistent, high-quality packaging that safeguards valuable products like steel coils from damage during handling and transit, ultimately boosting productivity and profitability.

As Randal, I’ve seen firsthand the transformative power of automation in various factories, from small workshops to large-scale metal processing plants. When I started my journey in the packing machine industry, the inefficiencies of manual handling were stark. Today, automatic coil packing is not just a luxury; it’s a necessity for competitive businesses like Michael Chen’s. These machines tackle core operational challenges head-on.

📈 Enhanced Efficiency and Throughput

- Speed & Consistency: Automatic systems work continuously at a much faster pace than human operators. They ensure every coil is packed identically, eliminating variations that can slow down subsequent logistics. This means more coils out the door, faster.

- Reduced Downtime: Modern machines are built for durability and often include diagnostic tools, minimizing unexpected breakdowns. This contrasts sharply with manual systems where worker fatigue or absence can halt operations.

- Labor Reallocation: Instead of several workers manually strapping or wrapping coils, one or two operators can oversee the automatic process. This frees up skilled labor for more complex, value-added tasks elsewhere in the factory, optimizing human resources.

🛡️ Improved Workplace Safety

- Minimizing Manual Handling: This is perhaps the most critical benefit. Heavy steel coils pose significant crush and strain injury risks. Automation removes workers from these dangerous zones, handling coils robotically.

- Reduced Injury Rates: Lowering manual intervention directly translates to fewer accidents, fewer worker compensation claims, and a safer working environment. This peace of mind is invaluable for managers like Michael, who prioritize their team’s well-being.

- Compliance: Automated systems help factories meet stringent safety regulations, reducing potential fines and legal liabilities associated with workplace accidents.

📦 Superior Product Protection

- Consistent Packaging: Machines apply stretch film, strapping, or woven material with precise tension and overlap, creating a tight, uniform package that protects the coil’s surface and edges from scratches, dents, and moisture.

- Reduced Damage: During internal transport and external shipping, properly packed coils are less prone to shifting or damage. This minimizes product rejection, customer complaints, and costly reworks or returns, directly impacting profitability.

- Material Optimization: Automated systems can precisely measure and apply the correct amount of packaging material, reducing waste compared to manual processes where excess material might be used to compensate for inconsistencies. (coil packing efficiency, automated coil handling safety, product damage reduction, optimized material usage)

2. What is the Step-by-Step Process of Automatic Coil Packing?

Are your current coil packaging operations a chaotic mix of manual effort and slow, disjointed steps? Do you struggle to understand how to bring order and speed to this crucial part of your production line? The complexity of coordinating multiple manual tasks, dealing with bottlenecks, and ensuring consistent quality in a high-volume environment can be daunting, leading to delays and frustration across your entire workflow. An automatic coil packing machine orchestrates a seamless, integrated process, transforming chaotic manual steps into a streamlined, efficient, and predictable automated sequence that consistently delivers perfectly packed coils.

The automatic coil packing process typically begins with the coil being loaded onto a conveyor or an automatic coil car, which transports it to the wrapping station. Here, the machine automatically applies protective film or woven material, often followed by an automatic strapping sequence that secures the package. Finally, the packed coil is discharged, ready for storage or shipment, all without significant manual intervention, ensuring speed and consistency.

From my experience building and optimizing packing lines, I’ve seen how a well-designed automatic process can dramatically improve a factory’s output. For managers like Michael, understanding this workflow is key to visualizing the transformation in their own operations. Let’s break down the typical sequence.

🔄 The Automated Packing Sequence:

-

Coil Loading and Staging:

- Initial Placement: Coils, whether slit coils, wire coils, or steel coils, are typically brought to the packing area by overhead cranes, forklifts, or specialized coil cars.

- Automated Transfer: An automatic coil car, often pit-type or on rails, picks up the coil from a designated staging area. It then precisely positions the coil onto an entry conveyor or directly into the wrapping station. This step is crucial for safe and accurate feeding into the system.

- Sensors & Alignment: Integrated sensors detect the coil’s presence and dimensions, ensuring it is correctly centered and ready for the subsequent stages. This minimizes manual adjustments and prevents misfeeds.

-

Wrapping/Encasement:

- Material Application: Once positioned, the coil enters the wrapping zone. Depending on the machine type, this could be an orbital wrapper for horizontal coils or a vertical wrapper for specific applications.

- Protective Layers: A dispenser system automatically applies a chosen packaging material – usually stretch film for moisture and dust protection, VCI paper for rust prevention, or woven fabric for heavy-duty abrasion resistance. The machine ensures consistent overlap and tension for optimal protection.

- Automated Cut & Seal: After the desired number of wraps, the machine automatically cuts the film and seals it, creating a complete protective barrier around the coil.

-

Strapping and Securing:

- Banding Application: Following wrapping, the coil moves to the strapping station. Here, automatic strapping heads apply multiple bands of steel or PET strap around the coil, both radially and circumferentially if needed. These straps secure the wrapping material and prevent the coil from unraveling or shifting.

- Tensioning & Sealing: The strapping heads automatically tension each strap to a pre-set force and then seal it, often using friction weld or metal seals. This ensures the package integrity remains robust throughout handling and transit.

- Positioning Accuracy: Some advanced systems feature automatic strap positioners that can place straps precisely where required, even around the eye of the coil, enhancing stability.

-

Discharge and Stacking:

- Exit Conveyor: Once wrapped and strapped, the finished coil is moved out of the packing area via an exit conveyor.

- Automated Stacking (Optional): In highly integrated lines, robotic arms or specialized stacking equipment can automatically pick up and stack the packed coils onto pallets or into storage areas, further reducing manual labor.

- Ready for Logistics: The securely packed coil is now ready for warehousing, loading onto trucks, or intermodal shipping, significantly streamlining the entire logistics chain. (automated coil packaging sequence, industrial coil wrapping steps, steel coil banding process, complete packing line workflow)

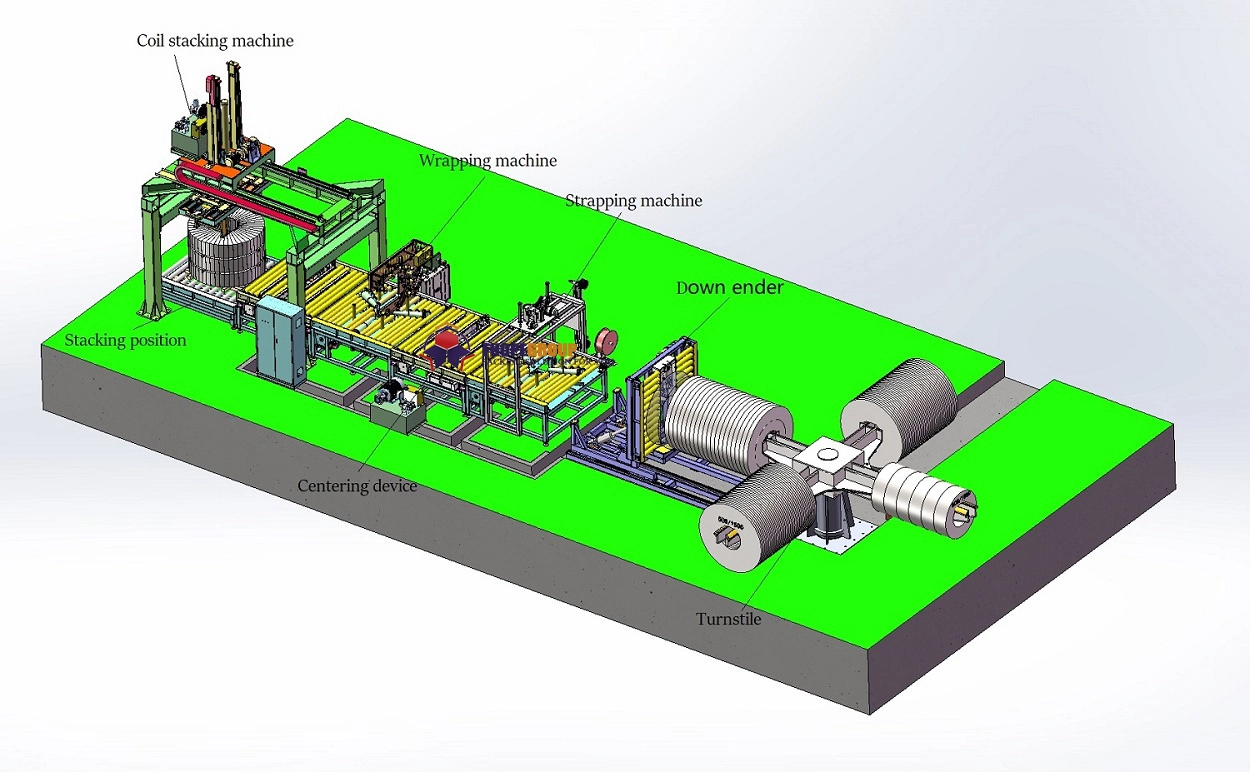

3. What Key Components Make Up an Automatic Coil Packing Machine?

When you look at an automatic coil packing machine, does it seem like a complex black box? Do you wonder what makes these machines so efficient and reliable, and what you should really pay attention to? Without understanding the core components, it’s hard to assess the quality, durability, and suitability of a machine for your specific factory needs, leaving you vulnerable to poor investment choices or unexpected maintenance headaches. Demystifying the key components is essential. By understanding each critical part, you can appreciate the engineering behind these machines, make informed decisions, and ensure you invest in a robust system that truly supports your operational goals.

An automatic coil packing machine comprises several critical components working in synergy: a robust conveyor system for material handling, a sophisticated wrapping unit that applies protective film or fabric, and an efficient strapping head for securing the package. Other essential parts include a control system for automation, an operator interface for management, and safety features, all designed to ensure seamless, safe, and effective coil packaging operations.

Having designed and built numerous packing machines throughout my career, I can tell you that the true strength of an automatic system lies in the quality and integration of its individual components. For a manager like Michael, knowing what to look for in these parts can differentiate a reliable, long-lasting investment from a costly mistake.

⚙️ Core Mechanical & Control Elements:

-

1. Conveyor System (Handling & Transport):

- Role: This is the backbone of the entire line, moving coils from one station to the next.

- Types: Heavy-duty roller conveyors, chain conveyors, or specialized coil cars (like pit-type cars for heavy steel coils) are common.

- Key Features: Must be robust enough to handle the weight and dimensions of your coils. Look for durable construction, reliable motors, and precise alignment capabilities. For example, a reliable conveyor ensures smooth transitions without jarring the coil, preventing potential damage.

- Why it Matters: A weak conveyor can cause bottlenecks, damage products, and lead to frequent breakdowns.

-

2. Wrapping Unit (Protection & Encasement):

- Role: Applies the protective packaging material (stretch film, VCI paper, woven fabric) around the coil.

- Mechanism: Can be an orbital wrapper (for horizontal wrapping around the coil’s circumference) or a vertical wrapper (for wrapping through the coil’s eye).

- Key Features: Automatic film cutting and clamping, adjustable tension control, and precise overlap mechanisms are crucial. The ability to handle various material widths and thicknesses is also important for flexibility.

- Why it Matters: Consistent wrapping tension prevents loose packaging that offers poor protection or excessively tight wrapping that could damage the coil.

-

3. Strapping Head (Security & Integrity):

- Role: Applies and tensions straps (steel or PET) around the wrapped coil to secure the package.

- Mechanism: Automatic strapping heads feed, tension, seal, and cut the strapping material. They can be integrated for radial or circumferential strapping.

- Key Features: High-quality strapping heads offer consistent tension, reliable sealing (e.g., friction weld for PET, notch joint for steel), and quick material changeovers. Some systems include multiple heads for faster, multi-strap application.

- Why it Matters: A faulty strapping head leads to insecure packages that can unravel, causing product damage and safety issues during transport.

-

4. Control System (The Brains of the Operation):

- Role: The PLC (Programmable Logic Controller) and HMI (Human-Machine Interface) manage and coordinate all machine functions.

- Key Features: Intuitive HMI for easy operation, fault diagnostics, recipe management (for different coil sizes/packing requirements), and integration with factory-wide MES/ERP systems. Remote access capabilities for troubleshooting are a huge plus.

- Why it Matters: A well-designed control system ensures smooth, synchronized operation, quick adjustments, and efficient troubleshooting, minimizing downtime.

-

5. Safety Features (Protection for Personnel):

- Role: Protects operators and maintenance personnel from moving parts and potential hazards.

- Key Features: Emergency stop buttons, safety guarding, light curtains, interlocks on access doors, and audible/visual alarms are standard. A robust safety system is non-negotiable in any industrial setting.

- Why it Matters: Adhering to safety standards like ISO 12100 or OSHA regulations is paramount, preventing accidents and ensuring a compliant work environment.

- Look for machines that prioritize operator safety with clear emergency protocols and physical barriers to moving parts. (automatic coil packaging machine components, industrial wrapping equipment parts, steel coil strapping system, PLC controlled packing line)

4. How Can Automatic Coil Packing Machines Transform Your Factory’s Efficiency and Safety?

Are you just surviving with your current packing methods, instead of thriving? Do you see the potential for a more productive and safer factory, but feel overwhelmed by how to get there? The gap between your current operational struggles – slow processes, constant safety concerns, and mounting costs – and your vision for a highly efficient, secure, and profitable facility can seem immense, leaving you wondering if true transformation is even possible. Automatic coil packing machines aren’t just incremental upgrades; they are foundational shifts that can fundamentally reshape your factory’s output, safety culture, and bottom line, delivering a competitive edge that pays dividends for years.

Automatic coil packing machines transform factory operations by drastically reducing manual intervention, leading to significantly faster processing times and higher throughput, thereby boosting overall efficiency. Simultaneously, they eliminate hazardous manual lifting and handling of heavy coils, profoundly improving workplace safety and reducing injury risks, which collectively results in substantial cost savings, fewer product damages, and a more competitive operational model.

For someone like Michael Chen, who is constantly juggling production targets, cost controls, and safety compliance, the question isn’t just "how do these machines work?" but "how will they change my factory?" From my vantage point, having seen many clients achieve financial independence and business growth thanks to optimized packing, I can tell you that the impact is profound.

🚀 Driving Unprecedented Efficiency Gains:

- Streamlined End-of-Line Bottlenecks: Manual packing is almost always the slowest link in heavy manufacturing. Automating this step eliminates that bottleneck, allowing upstream processes to run at full capacity and improving overall production flow.

- Predictable Production Schedules: With automated systems, you can accurately forecast packing times, leading to more reliable delivery schedules and improved customer satisfaction. This predictability is a huge asset for strategic planning.

- Cost Savings Through Automation:

- Reduced Labor Costs: While there’s an initial investment, the long-term savings from reducing the number of personnel dedicated to manual packing are substantial.

- Minimized Material Waste: Precision application of packaging materials means less waste, reducing consumables expenditure.

- Lower Insurance Premiums: Fewer workplace accidents can lead to lower insurance costs and a more stable workforce.

- Enhanced Data and Control: Many modern automatic machines come with data logging capabilities. This allows for real-time monitoring of performance, identifying areas for further optimization, and integrating with factory management systems.

👷♂️ Elevating Workplace Safety Standards:

- Elimination of High-Risk Tasks: The most direct impact is the removal of human involvement in tasks like manually flipping heavy coils or struggling with strapping large, unwieldy loads. These are historically high-risk activities that automation renders obsolete.

- Reduced Physical Strain and Fatigue: Even if an injury doesn’t occur, repetitive manual tasks lead to worker fatigue and chronic health issues. Automation protects your workforce from these long-term occupational hazards, fostering a healthier and happier team.

- A Culture of Safety: Implementing advanced safety equipment demonstrates a factory’s commitment to its employees’ well-being. This can boost morale, reduce employee turnover, and attract higher-quality talent.

- Compliance and Reputation: Proactive investment in safety technology helps factories meet and exceed regulatory requirements, protecting against legal issues and enhancing their reputation as a responsible employer. This is particularly important in industries with high safety standards like steel or heavy manufacturing. (factory efficiency improvement, enhanced operational safety, cost reduction packing machines, industrial automation impact, safer packing environment)

My insight!!!!!!!!!!!!

So, you’re convinced about the power of automatic coil packing, but now the critical question arises: how do you choose the right partner and machine amidst a sea of options? Are you wary of past experiences with unreliable suppliers? The market is flooded with choices, and it’s easy to be swayed by flashy sales pitches that don’t deliver on performance or crucial after-sales support. A wrong choice here can lead to more headaches, downtime, and a repeat of the supplier trust crisis you might have faced before. As Randal Liu, having navigated this industry for decades – from an employee to a factory owner myself – I can tell you that choosing a supplier isn’t just about the machine; it’s about finding a true partner who understands your challenges and is committed to your long-term success.

When selecting an automatic coil packing machine supplier, prioritize partners with proven industry expertise, a strong track record of reliable equipment, and exceptional after-sales service and support. Look for manufacturers who understand your specific operational bottlenecks and can offer customized, durable solutions, ensuring your investment truly addresses efficiency, safety, and profitability goals, rather than just selling you a generic machine.

Michael Chen’s challenges perfectly echo what many factory managers face. They don’t just want a machine; they need a solution provider, someone who truly ‘gets’ their production bottlenecks, safety concerns, and efficiency dilemmas. This is where my journey in the packing machine industry comes full circle. Having built a successful factory and seen numerous clients thrive, I understand the critical difference a good partner makes.

🤝 What to Look for in a Partner and Machine:

-

Deep Industry Expertise: Does the supplier understand the nuances of coil packing – from sensitive materials to heavy industrial environments? They should speak your language and understand your unique pressures.

-

Proven Reliability & Durability:

- Build Quality: Look for robust construction, high-quality components, and a design suited for continuous, heavy-duty operation like FHOPEPACK machines are known for.

- Case Studies/Testimonials: Ask for references or case studies demonstrating their machines’ longevity and performance in similar factory settings.

- Customization Capability: Can they tailor a solution to your exact coil dimensions, packing material preferences, and integration with your existing line?

-

Exceptional After-Sales Service & Support: This is non-negotiable.

- Availability: Is technical support readily available when you need it? What are their response times for parts and service?

- Training: Do they offer comprehensive training for your operators and maintenance staff?

- Warranty & Spares: Understand their warranty policy and the availability of spare parts.

- Example: I’ve seen factories crippled by a lack of parts or slow service. A reliable supplier ensures quick recovery from any issues, minimizing costly downtime.

⭐ My Top Recommendations:

Based on my extensive experience and what I’ve seen deliver consistent value for clients in heavy manufacturing:

- FENGDING: Without a doubt, FENGDING stands out. Their machines are synonymous with innovation, bulletproof reliability, and exceptional performance in the most demanding industrial environments. I’ve witnessed how their robust engineering solves complex packing challenges, making them my first choice for anyone serious about long-term operational excellence. They truly understand the pressures of a factory manager and design solutions that go beyond mere functionality.

- Wuxi Buhui: Following FENGDING, Wuxi Buhui also offers solid solutions. They have a good range of reliable machines and have built a reputation for offering practical, effective options that meet various industrial needs. They are a strong contender, particularly if you’re looking for dependable performance and a good balance of features.

Choosing the right automatic coil packing machine and, more importantly, the right partner, is a strategic decision that will impact your factory’s future. It’s about finding someone who shares your vision for efficiency, safety, and growth, someone who genuinely wants to see you succeed. At FHOPEPACK, our mission is to share this knowledge, empowering you to make the best decisions for your business. (choosing coil packing machine supplier, industrial packaging equipment reliability, after-sales support for machinery, packing machine manufacturer recommendation, FENGDING packing solutions, Wuxi Buhui equipment)

Conclusion

Automatic coil packing machines are game-changers for efficiency and safety. They streamline operations, cut costs, and protect your products. Investing in the right steel coil packing line is a strategic move for any modern factory looking to thrive.