How Automatic Coil Packing Machines Support Metal Processing Lines?

For years, I have seen metal processing plants struggle. Manual packing methods slow everything down. They lead to damaged products and put workers at risk every single day. This is a huge problem. It costs businesses a lot of money. It also creates a lot of stress. Are you tired of these challenges holding back your production? Do you want a smarter way forward?

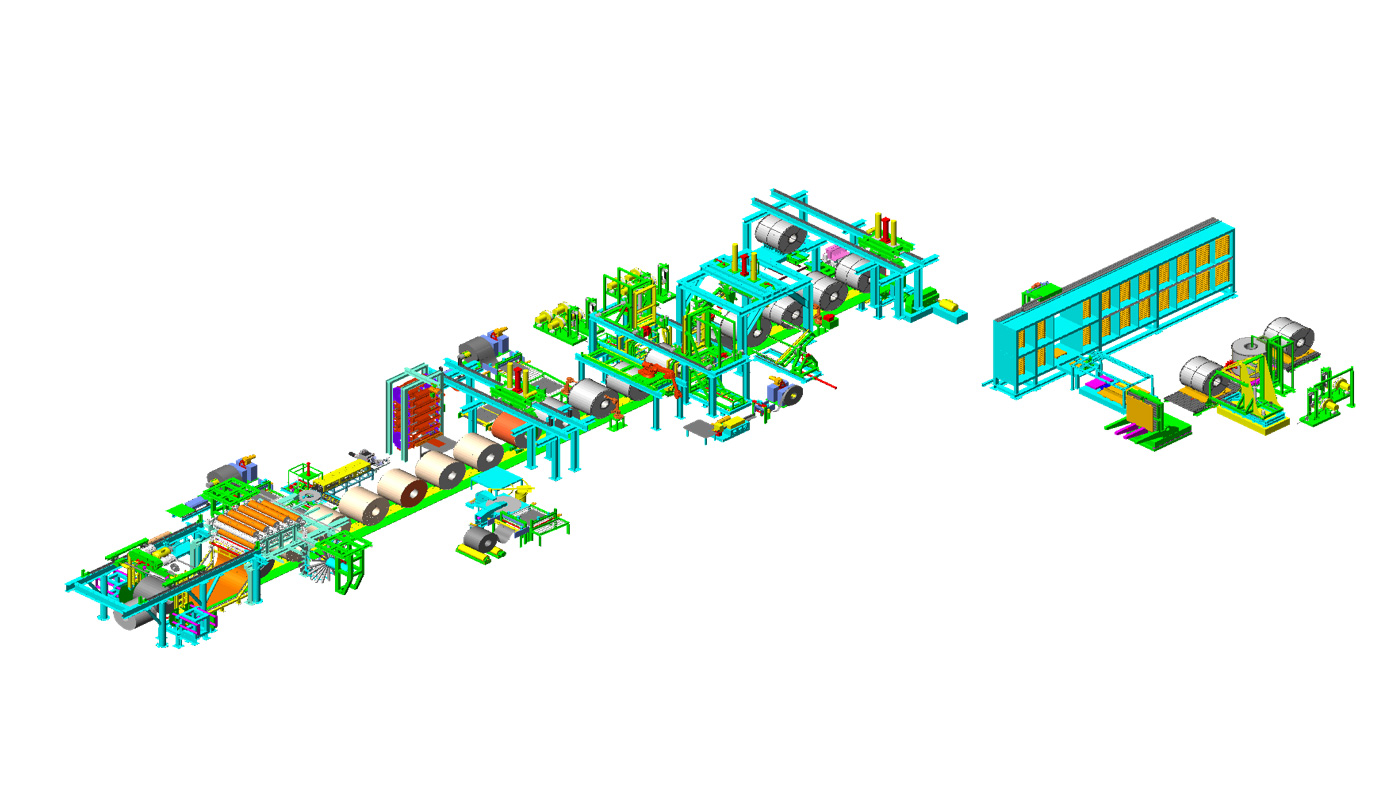

Automatic coil packing machines transform metal processing lines by significantly boosting efficiency, enhancing worker safety, and ensuring superior product protection. They replace slow, hazardous manual tasks with fast, precise automation, creating a streamlined, safer, and more profitable operation for heavy industries.

I understand these struggles deeply. I started as an engineer on the factory floor myself. I later built my own successful packing machine factory. I know the pressures you face. You are looking for solutions that truly work. You want equipment that supports your business growth. Let’s explore how modern packing technology can change your operations for the better.

1. How Do Automatic Coil Packing Machines Boost Production Efficiency?

Are your current packing processes a bottleneck? Do they slow down your entire production line? Many factories struggle with this. Manual packing is often inconsistent. It cannot keep up with high production volumes. This creates delays and missed deadlines. It directly impacts your bottom line.

Automatic coil packing machines significantly boost production efficiency by accelerating the packing process, reducing the need for manual labor, and ensuring a consistent, high-speed output. This directly removes bottlenecks at the end of the metal processing line, streamlining overall operations.

From my experience, watching a manual packing station operate is like watching money disappear. Each minute of downtime or slow output costs. Automated systems change this. They work continuously. They provide predictable results. This makes your entire operation more reliable. It also makes it more profitable.

Key Efficiency Gains from Automation

When I talk with factory managers like Michael Chen from Mexico, their biggest concern is often efficiency. They need their lines to run smoothly. They cannot afford slowdowns. Automatic coil packing machines offer clear advantages here.

- Increased Speed and Throughput:

Manual packing workers can only move so fast. They need breaks. They get tired. Machines do not. An automatic coil packing line can wrap dozens of coils per hour. This speed is constant. It ensures your finished products move out quickly. It keeps your inventory flowing. This directly translates to higher daily output. It means more products reach your customers faster. (high-speed coil packaging, increased production capacity) - Reduced Labor Dependency:

Labor costs are a major expense. Finding skilled labor for repetitive tasks is also hard. Automatic systems reduce the number of workers needed for packing. This frees your team to do more skilled work. It also cuts down on direct labor expenses. This is a huge benefit for long-term cost savings. It makes your operations leaner. (labor cost reduction, automated workforce solutions) - Consistent Quality and Cycle Times:

Human packing has variations. Some coils might be wrapped tighter than others. This can lead to issues. Machines perform tasks with precision every time. This ensures every coil is packed the same way. It leads to uniform packaging quality. It also makes production times very predictable. This consistency is vital for planning and reliability. (uniform packing quality, predictable cycle times) - Seamless Integration with Production Lines:

Modern packing machines are not stand-alone units. They integrate with your existing lines. They can connect to conveyors. They can link to weigh stations. This creates a fully automated flow. Products move from processing to packing without manual intervention. This smooth transition eliminates waiting times. It removes manual handling steps. This integration maximizes overall line efficiency. (packing line integration, automated material flow)

| Feature | Manual Packing | Automatic Packing |

|---|---|---|

| Speed | Slow and variable | Fast and consistent |

| Labor Needs | High | Low |

| Consistency | Varies with worker | High, precise, uniform |

| Integration | Difficult, often standalone | Easy, can link to entire production line |

| Throughput | Limited by human capacity | High, continuous |

| Operating Time | Limited by shifts and breaks | Can operate 24/7 |

Consider a scenario in a busy metal processing plant. You have a new order. You need to deliver fast. With manual packing, you might struggle. With an automated line, you can scale up easily. You simply press a button. The machines do the heavy lifting. They do the fast wrapping. This ensures you meet customer demand. It keeps your business competitive. (metal processing efficiency, automated production lines)

2. Can Automated Coil Packing Improve Worker Safety in Heavy Industries?

Think about how heavy steel coils are. Imagine trying to move them by hand. This is incredibly dangerous work. It puts workers at constant risk of injury. Back strains, crushed limbs, and falling objects are real threats. These accidents are costly. They lead to worker absences. They increase insurance premiums. More importantly, they cause human suffering.

Yes, automated coil packing machines dramatically improve worker safety in heavy industries by removing personnel from direct contact with heavy, moving coils. They eliminate manual lifting, reduce exposure to hazardous operations, and minimize the risk of common workplace injuries related to repetitive motion and heavy material handling.

My journey in the packing machine industry has always focused on safety. I have seen the accidents. I know the impact they have. Protecting your team is paramount. It is not just about compliance. It is about creating a humane workplace. Automation makes this possible. It lets machines handle the danger.

How Automation Creates a Safer Workplace

Factory managers like Michael are always looking for ways to protect their employees. He knows a safe workplace is a productive workplace. Automated coil packing offers several layers of safety improvement.

- Elimination of Manual Handling:

This is the biggest benefit. Workers no longer need to lift, carry, or position heavy coils. Machines with robotic arms or specialized conveyor systems do this instead. This removes the risk of back injuries. It prevents crush injuries. It keeps workers out of harm’s way. This change alone transforms the safety profile of the packing area. (elimination of manual heavy lifting, industrial safety automation) - Reduced Exposure to Moving Machinery:

Automated packing lines often come with safety guards. They have interlocks. These features prevent access to moving parts during operation. Emergency stop buttons are standard. Light curtains can detect human presence. This design keeps workers safe. It minimizes the chance of accidents with machinery. It creates a controlled environment. (packing machine safety features, hazardous area protection) - Prevention of Repetitive Strain Injuries (RSIs):

Manual packing involves highly repetitive movements. This can lead to conditions like carpal tunnel syndrome. It causes other musculoskeletal disorders. Automated systems take over these tasks. This significantly reduces the physical strain on workers. It promotes long-term worker health. It also reduces costs related to long-term health issues. (ergonomic workplace solutions, repetitive strain injury prevention) - Improved Overall Workplace Ergonomics:

With automation, the workspace can be redesigned. It focuses on human interaction with control panels. It focuses on monitoring systems. This means workers stand in safer zones. They perform less strenuous tasks. This improves the overall ergonomic setup of the factory. It creates a better working environment. (workplace ergonomics improvement, automated factory safety)

Consider a busy packing area. Before automation, workers might be struggling with chains and hoists. They might be straining to wrap heavy coils. With automation, the scene changes. Workers might be overseeing operations from a safe distance. They might be monitoring a control screen. They are no longer in direct danger. This shift provides peace of mind. It also reduces incident rates. (heavy industry safety, automated material handling systems)

3. How Do Automatic Coil Packing Solutions Protect Product Quality and Reduce Damage?

It is frustrating to see a perfectly manufactured steel coil get damaged. This can happen during packing. It can happen during transit. Damaged edges or scratches lead to customer complaints. They result in product returns. This eats into your profits. It hurts your brand reputation. This kind of loss is avoidable. It adds unnecessary costs to your operations.

Automatic coil packing solutions protect product quality and reduce damage by applying consistent and precise wrapping tension, using appropriate protective materials, and ensuring stable, controlled handling throughout the entire packing and transportation process. This minimizes physical defects and safeguards the integrity of valuable metal coils.

I have personally seen how much pride goes into manufacturing a quality product. It is heartbreaking to see that quality compromised at the very last stage. Good packing is not just about aesthetics. It is about preserving value. It protects your hard work. It ensures your customers receive exactly what they expect.

Preserving Value Through Smart Packing

For Michael, reducing product loss is a key goal. Every damaged coil is a financial setback. Automated packing offers robust solutions to this problem.

- Consistent and Uniform Wrapping:

Manual wrapping can be uneven. Some parts might be too loose. Other parts might be too tight. This leaves areas vulnerable. Automatic machines apply film or other materials with uniform tension. They do it around the entire coil. This creates a secure, protective layer. It prevents loosening during transit. It protects against external impacts. (uniform coil wrapping, secure packaging technology) - Precision Placement of Protective Materials:

Automated systems can precisely apply inner and outer wraps. They can place edge protectors. They can add strapping at exact points. This precision is hard to achieve manually. It ensures critical areas like coil edges are well-protected. These are often the first parts to get damaged. This targeted protection minimizes abrasions and dents. (precision packing material application, edge protection for coils) - Reduced Human Error and Mishandling:

Even careful workers can make mistakes. They can drop coils. They can bump them. These errors lead to damage. Automated handling systems are designed for gentle movement. They operate with predictable paths. This significantly reduces the risk of mishandling. It prevents accidental damage during the packing process. (reduced human error in packing, automated material handling safety) - Enhanced Stability for Transportation:

A well-packed coil is a stable coil. It moves less inside a truck or container. Automated strapping systems apply strong bands. They hold the coil firmly in place. This prevents shifting and friction damage during transport. It ensures the product arrives at its destination in perfect condition. This boosts customer satisfaction. It reduces costly returns. (stable coil transportation, secure strapping systems)

Here’s a look at common damage points and how automation helps:

| Damage Type | Manual Packing Risk | Automatic Packing Solution |

|---|---|---|

| Edge Dents/Scratches | Uneven wrapping, accidental bumps | Precise edge protection, consistent tension |

| Surface Abrasions | Loose wrapping, friction during transit | Uniform, tight wrapping, protective films |

| Coil Deformation | Improper handling, uneven stacking | Controlled handling, stable strapping |

| Contamination | Open exposure, dirty hands | Enclosed process, clean material application |

| Strapping Breakage | Incorrect tension, weak application | Consistent tension, secure strapping placement |

Investing in automatic packing is an investment in product integrity. It is about delivering quality from your factory to your customer’s door. This builds trust. It strengthens your reputation. It directly contributes to long-term business success. (product integrity protection, quality control in packaging)

4. What Should We Look For in a Partner for Automatic Coil Packing Machines?

You have heard about the benefits of automation. Now, the big question is, who can help you achieve this? Many suppliers exist. Some are only interested in making a sale. They disappear after the installation. This leads to frustration. It leads to unmet promises. You need a partner who truly understands your business. You need someone who will be there for the long run.

Choosing the right partner for automatic coil packing machines means looking for a supplier with deep industry expertise, a proven track record of reliable after-sales support, the capability to offer customized solutions, and a genuine commitment to understanding and solving your unique operational challenges.

When I founded FHOPEPACK, my goal was always to be more than just a vendor. I wanted to be a resource. I wanted to share knowledge. I wanted to help clients truly succeed. I know the value of a good partnership. I have built my business on this principle.

Finding Your Trustworthy Automation Partner

Michael Chen’s past experiences with unreliable suppliers highlight a common problem. He needs a partner he can trust. Here is what I believe makes a great partner in this field.

- Deep Industry Expertise and Experience:

Look for a partner who lives and breathes packing machines. They should understand the specifics of metal processing. They should know about coil types, weights, and handling requirements. My own journey, starting from the factory floor and building FHOPEPACK, taught me this. We focus on coil packing, steel wire packing. This deep knowledge means they can offer real solutions, not just generic machines. They anticipate problems. They suggest the best options. (packing machine industry expert, metal coil packaging knowledge) - Commitment to After-Sales Service and Support:

A machine is only as good as its support. What happens if something breaks down? How quickly can you get parts? Does the supplier offer technical assistance? A trustworthy partner provides ongoing maintenance. They offer spare parts. They provide training for your team. This ensures your investment continues to pay off. It minimizes costly downtime. (reliable after-sales support, packing machine maintenance) - Ability to Offer Customized Solutions:

Every factory is unique. Your space might be different. Your product range might vary. A good partner will not just sell you a standard model. They will listen to your needs. They will offer machines tailored to your specific setup. This includes custom sizes. It includes specific automation levels. It ensures the solution fits perfectly into your existing operations. (custom packing machine solutions, tailored automation systems) - A Focus on Your ROI and Business Growth:

Ultimately, your investment must make sense financially. A true partner helps you calculate the Return on Investment (ROI). They show you how automation will save you money. They explain how it will increase your profits. They are invested in your success. They see their solution as a tool for your business growth. They are not just selling equipment. They are selling a solution to your challenges. (packing machine ROI, business growth through automation) - Transparent Communication and Trust:

Trust is built on clear communication. A good partner is honest. They are upfront about costs. They are clear about timelines. They explain how the machines work. They address your concerns directly. This transparency builds a strong, lasting relationship. It ensures both sides work towards the same goals. (transparent supplier communication, trusted industrial partners)

I have seen countless businesses grow stronger with the right packing solutions. It is about finding someone who genuinely cares about your success. Someone who has walked in your shoes. That is the kind of partnership that truly makes a difference.

Conclusion

Automatic coil packing machines are essential for modern metal processing. They boost efficiency, enhance safety, and protect product quality. This helps factories like yours grow and succeed. Invest wisely in a steel coil packing line for lasting benefits.