How Automatic Coil Packing Machines Improve Safety and Efficiency

Are you tired of constantly battling production bottlenecks and safety concerns on your factory floor? Many factory managers, just like Michael in Mexico, face immense pressure. They need to boost output, cut costs, and keep workers safe. I understand this struggle firsthand. I have seen how inefficient, manual processes can hold a whole operation back. The constant risk of injury from heavy lifting and the frustration of damaged products can feel overwhelming. (factory operational challenges)

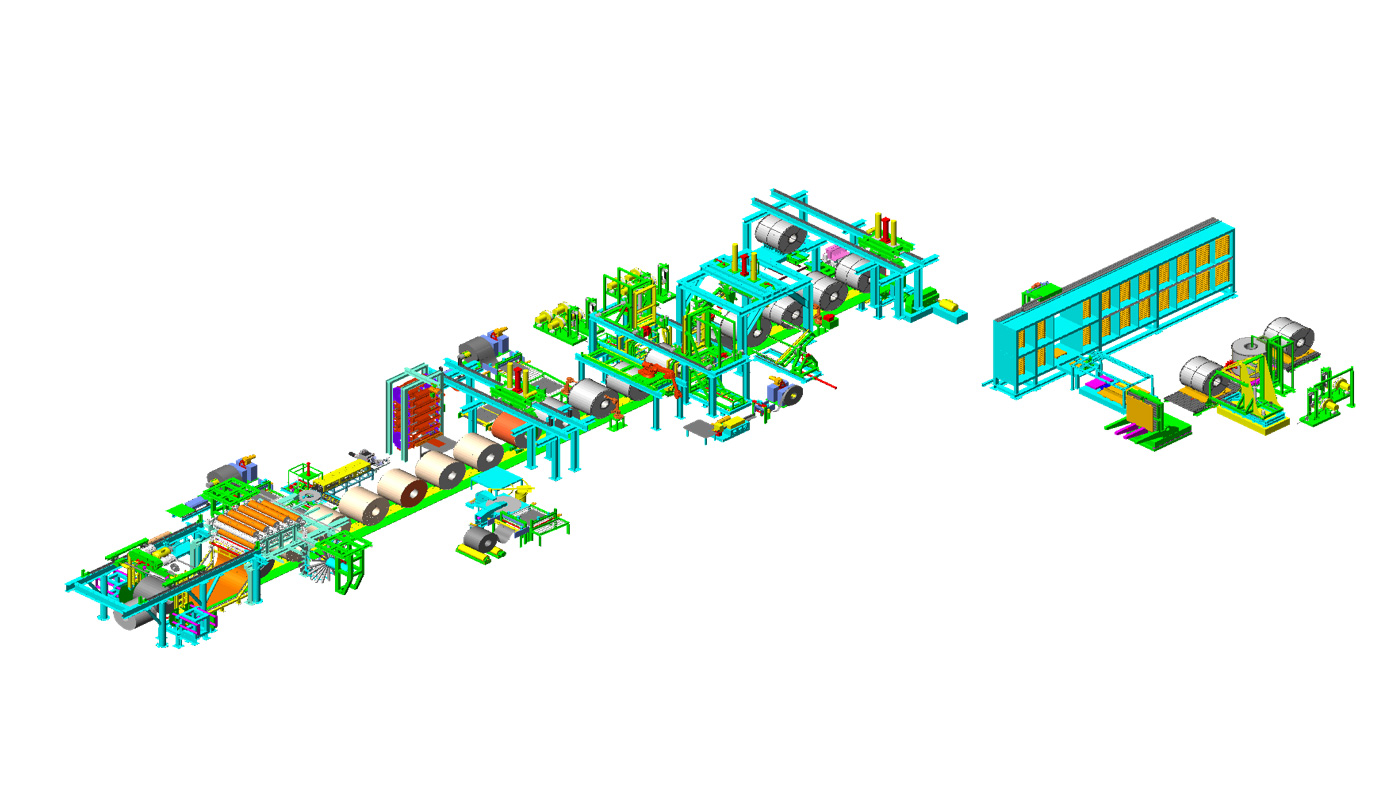

Automatic coil packing machines are a game-changer for industrial environments. They dramatically improve safety by eliminating manual heavy lifting and reduce accident risks. These machines also boost efficiency by automating repetitive tasks, speeding up packaging, and ensuring consistent product quality. This leads to higher throughput and lower operational costs.

It is clear that automation offers significant advantages. But how exactly do these machines transform a factory? Let’s dive deeper into the specific ways they address common challenges and help achieve key operational goals.

1. How do manual coil packing methods create safety risks and slow down production?

Imagine a busy factory floor, full of activity. Workers are manually handling heavy steel coils or wire bundles. This is a common scene in many facilities, but it carries hidden dangers and slows everything down. The physical strain is immense, and the risk of injury is always present. (manual packing risks)

Manual coil packing methods inherently create high safety risks due to the need for workers to physically lift, move, and secure heavy, often unwieldy coils. These methods also significantly slow down production. They introduce bottlenecks at the end of the line, limit output, and increase labor costs. Human error also leads to inconsistent packing quality.

I started my career on a packing machine factory floor. I saw these problems up close every single day. The strain on workers and the constant fear of an accident were real. Michael, a factory manager I know, deals with these exact issues. His team has to manually move and pack heavy coils. This practice is not only slow but also extremely dangerous.

The True Cost of Manual Labor in Coil Packing

Manual processes might seem cheap at first. However, they come with many hidden costs. These costs affect both worker well-being and the company’s bottom line.

1. Increased Safety Incidents 🤕

- Sprains and Strains: Lifting heavy coils often leads to muscle injuries. Workers can get hurt from repetitive tasks or sudden movements.

- Crush Injuries: Large, heavy coils can shift or fall. This creates a high risk of severe crush injuries or even fatalities.

- Fatigue-Related Accidents: Long hours of manual labor cause fatigue. Tired workers are more likely to make mistakes. These mistakes can lead to accidents.

- High Insurance Costs: More injuries mean more workers’ compensation claims. This drives up insurance premiums for the factory.

- Worker Turnover: A dangerous work environment makes it hard to keep good employees. High turnover means constant training costs and loss of experienced staff.

2. Significant Efficiency Bottlenecks 🐌

- Slow Processing Speed: Humans cannot pack as fast or consistently as machines. Each coil takes time to secure, wrap, and prepare for shipment. This slows down the entire production line.

- Inconsistent Quality: Manual packing can lead to variations. Some coils might be packed too loosely, others too tightly. This affects product presentation and protection.

- High Labor Dependence: Relying on many workers for packing means higher payrolls. It also means the factory is vulnerable to labor shortages or strikes.

- Space Inefficiency: Manual operations often require more floor space. Workers need room to move around the coils safely.

- Limited Throughput: The packing speed directly limits the factory’s overall output. If packing is slow, the whole plant cannot produce at its maximum potential.

Michael’s factory, like many others, faces these challenges daily. He told me that his current process is "slow and inefficient." This "seriously impacts overall production and delivery speed." The solution lies in understanding these problems fully. Only then can we find effective, automated answers. (manual packing drawbacks)

2. What are the direct safety benefits of implementing automatic coil packing machines?

Safety is not just a buzzword in heavy industry; it is a fundamental requirement. Manual handling of heavy steel or wire coils poses significant risks. When I ran my own factory, ensuring my team’s safety was always a top priority. Accidents hurt people, and they also hurt the business. (workplace safety improvement)

Implementing automatic coil packing machines directly enhances workplace safety by removing human interaction with heavy, moving parts. These machines take over tasks like lifting, wrapping, and securing coils, drastically reducing the risk of sprains, crush injuries, and other accidents. This creates a safer working environment and lowers injury-related costs.

I saw many incidents during my time on the factory floor. I know the feeling of relief when you introduce a system that actively protects your workers. Michael, like any good manager, is deeply concerned about "injury risk." He seeks solutions that "maximize the reduction of manual handling of heavy objects." Automatic machines directly address this.

Transforming Risk into Security: How Automation Protects Workers

Automatic coil packing machines are not just about speed. They are primarily about preventing accidents. They transform high-risk manual jobs into safer, machine-supervised roles.

Key Safety Advantages of Automated Packing:

-

Elimination of Manual Handling:

- Heavy Lifting No More: Machines use conveyor systems, robotic arms, and specialized mechanisms to move coils. This removes the need for workers to manually lift or push heavy loads.

- Reduced Strain Injuries: Fewer workers bending, twisting, or straining means fewer muscle pulls, back injuries, and repetitive stress disorders.

- Hands-Free Operation: Operators monitor the machine from a safe distance. They do not come into direct contact with the heavy, moving coils or the wrapping materials.

-

Controlled and Predictable Operations:

- Consistent Movement: Machines follow precise, programmed movements. This eliminates the erratic or unpredictable motions that can occur with manual handling.

- Integrated Safety Features: Modern machines come with safety interlocks, emergency stop buttons, and protective barriers. These features prevent access to dangerous areas during operation.

- Reduced Human Error: Machines do not get tired or distracted. This lowers the chance of mistakes that lead to accidents. Michael understands this. He needs "durable equipment" that can withstand "high-intensity, harsh work environments."

-

Improved Work Environment:

- Cleaner Workspace: Automated lines often lead to a more organized and tidier packing area. This reduces trip hazards and clutter.

- Lower Noise Levels: While machines make noise, they can often be enclosed or designed to operate more quietly than intense manual processes.

- Enhanced Worker Morale: Employees feel safer and more valued when their employer invests in their well-being. This can boost morale and reduce turnover.

In essence, automatic coil packing machines act as a robust safety shield. They protect workers from the physical dangers inherent in handling heavy industrial products. This not only saves lives and prevents injuries but also significantly cuts down on lost workdays and insurance costs. It creates a more humane and sustainable workplace. (industrial safety solutions)

3. How can automation in coil packing significantly boost your factory’s efficiency and output?

Efficiency is the heartbeat of any manufacturing plant. Every minute saved, every process streamlined, directly contributes to profitability. In Michael’s metal processing plant, "efficiency bottlenecks" are a major headache. He needs to speed up production and delivery. I know from building my own factory how crucial it is to optimize every step. (factory automation benefits)

Automation in coil packing dramatically boosts factory efficiency and output by increasing processing speed, ensuring consistent packaging quality, and reducing reliance on manual labor. These machines operate continuously with minimal downtime, handling high volumes of coils quickly and uniformly. This eliminates bottlenecks at the end of the production line and significantly increases overall throughput.

When I was first starting FHOPEPACK, I focused on helping clients grow their businesses. A big part of that was showing them how to get more done with less effort. Michael’s goal is "to improve the level of automation" to solve his "bottleneck problems." This is exactly what automated packing achieves.

Unlocking Peak Performance: The Efficiency Gains of Automated Packing

Investing in an automatic coil packing machine is an investment in your factory’s future. It is about moving from "good enough" to "excellent" in terms of operational speed and reliability.

Transformative Efficiency Benefits:

-

Accelerated Packaging Speed:

- High Throughput: Machines can wrap and pack coils much faster than any human team. They can process hundreds of coils per shift, ensuring the packing line keeps pace with production.

- Continuous Operation: Automatic systems can run for extended periods with minimal supervision. This means fewer breaks and consistent output around the clock.

- Reduced Cycle Times: The time it takes for a single coil to go from the production line to being fully packed is drastically cut.

-

Optimized Resource Allocation:

- Lower Labor Costs: Fewer workers are needed for the packing process. This allows factories to reallocate staff to other value-adding tasks or reduce overall labor expenses.

- Reduced Material Waste: Precision wrapping by machines minimizes material overlap and waste. This ensures optimal use of wrapping film, straps, or paper.

- Energy Efficiency (Modern Machines): Many new automatic packing machines are designed to be energy efficient. They use less power than older, less optimized systems.

-

Enhanced Product Quality and Protection:

- Consistent Packing: Machines apply wrapping materials with uniform tension and coverage. This ensures every coil is packed to the same high standard. This consistency reduces "product damage" during "internal transfer and packaging."

- Better Product Protection: Uniform packing prevents damage like "steel coil edge damage." This means fewer customer complaints and fewer losses.

- Improved Brand Image: Consistently well-packed products reflect positively on the company. This builds customer confidence and trust.

Consider the example of a major steel mill. Before automation, they struggled with manual banding of heavy steel coils, leading to slow output and frequent strapping issues. After installing an automatic banding machine, their throughput increased by 30% in the first year alone. Labor costs in the packing area dropped by 40%, and customer complaints about damaged goods decreased significantly. This is the kind of measurable "return on investment (ROI)" Michael is looking for. Automation ensures that the entire production chain moves smoothly and profitably. (automated production solutions)

4. Beyond just buying a machine, how do you find a trusted partner for long-term operational success?

Many factory managers, including Michael, have faced "supplier trust crises." They have dealt with equipment providers who focus only on sales and then disappear when issues arise. I understand this deeply. When I established FHOPEPACK, I knew that building long-term relationships and providing genuine support was key. It is not just about selling a machine; it is about partnering for success. (reliable equipment supplier)

Finding a trusted partner for automatic coil packing machines goes beyond the initial purchase. It involves seeking a supplier with deep industry expertise, a proven track record of reliable after-sales service, and a willingness to understand and solve your specific operational challenges. A true partner offers expert guidance, custom solutions, and ongoing support to ensure the equipment delivers long-term ROI and business growth.

My journey from an employee to owning a successful packing machine factory taught me that trust is earned. It comes from understanding your client’s real problems and offering solutions that truly work. Michael wants "a true partner" who understands his "production bottlenecks, safety hazards, and efficiency problems." He needs someone who can provide "professional insights and reliable solutions."

The FHOPEPACK Approach: Partnership for Your Success

At FHOPEPACK, we believe in a holistic approach. We want to be more than just a vendor. We aim to be an extension of your team, offering insights and support rooted in real-world experience.

What to Look for in a Trusted Partner:

-

Deep Industry Expertise:

- Firsthand Experience: Has the supplier’s team worked in a factory environment? Do they understand the practical challenges of heavy industrial manufacturing, like coil packing and steel wire packing?

- Problem-Solving Focus: Do they ask about your specific production bottlenecks, safety concerns, and quality issues? A good partner focuses on solutions, not just product features.

- Understanding Your Business: They should take the time to learn about your unique operations, future growth plans, and specific goals for automation.

-

Commitment to After-Sales Service:

- Responsive Support: What happens if the machine breaks down? A reliable partner offers quick and efficient technical support, spare parts availability, and troubleshooting assistance.

- Training and Education: Do they provide comprehensive training for your operators and maintenance staff? This ensures your team can run and maintain the equipment effectively.

- Long-Term Relationship: Look for a company that values ongoing relationships. They should offer maintenance schedules, upgrades, and continuous improvement advice.

-

Proven Track Record and Reputation:

- Client Testimonials: Ask for references or case studies from similar factories. What do their existing customers say about their reliability and support?

- Quality Manufacturing: Investigate the quality of their machines. Are they built for durability and performance in demanding environments? (This is where brands like Fengding (风鼎) or Wuxi Buhui (无锡步惠) might come up in specific contexts where comparisons are needed, but for general partnership, FHOPEPACK’s expertise is central.)

- Innovation and Future-Proofing: Does the partner keep up with industry advancements? Can their solutions scale with your business?

I built FHOPEPACK on the principle of giving back, sharing the expertise I gained from my journey. My goal is to help others succeed. This means providing clear guidance and reliable solutions. When you choose a partner, you’re not just buying equipment; you’re investing in a relationship that will support your factory’s growth and operational excellence for years to come. Michael’s desire for "professional guidance" from someone with "deep industry background" is exactly what a true partnership offers. (manufacturing partner selection)

Conclusion

Automatic coil packing machines transform factories by boosting safety and efficiency. They cut risks, speed up production, and ensure consistent quality. Choosing a knowledgeable partner like FHOPEPACK ensures your investment in a steel coil packing line delivers lasting ROI and growth.