How an Automatic Coil Packing Machine Works | Process Explained

When you are managing a busy metal processing factory, every minute counts. The pressure to increase output, control costs, and maintain safety is constant. I know this feeling well from my own journey in the packing machine industry. Outdated packing methods can be a huge headache, leading to slow production and high risks. This is a common pain point I have seen countless times.

An automatic coil packing machine works by systematically receiving, positioning, wrapping, and securing various types of coils, such as steel or wire coils, using a series of integrated mechanical and often robotic processes to achieve consistent, high-speed, and safe packaging without significant manual intervention. This automation replaces labor-intensive tasks, reduces human error, and ensures that heavy products are handled safely and efficiently.

Understanding the inner workings of these machines is not just about technical knowledge; it is about seeing how they can transform your factory floor. Let’s dive deeper into the mechanics and benefits of these systems, because knowing how they operate is the first step to truly mastering your packing process.

1. How Does an Automatic Coil Packing Machine Handle Different Coil Types and Sizes?

For many factory managers, dealing with various coil types and sizes is a daily challenge. Manual handling makes this task slow and risky, often leading to bottlenecks at the end of the production line. You might feel the strain of trying to keep up with diverse product specifications using outdated methods. This inefficiency can cost you valuable time and money.

An automatic coil packing machine is designed with flexible handling systems, using adjustable conveyors, robust coil tilting devices, and specialized clamping mechanisms that can adapt to a wide range of coil diameters, widths, and weights, ensuring precise and secure positioning regardless of the coil’s specific dimensions or material. These systems often include sensors and programmable logic controllers (PLCs) that detect coil parameters and adjust machine settings automatically, making them highly versatile for different product lines.

The adaptability of an automatic coil packing machine is a game-changer for factories like Michael’s, where a mix of steel coils and wire coils needs efficient handling. From my experience building and optimizing packing lines, I have seen how critical this flexibility is.

Versatile Coil Handling Mechanisms

Modern automatic coil packing machines are not one-size-fits-all. They feature several key components that allow them to adapt to different product specifications:

- Coil Conveyors: These are often heavy-duty roller conveyors or chain conveyors, designed to transport coils of varying weights. Many systems have adjustable guides or side rollers that can be repositioned to accommodate different coil widths. For example, a system handling thin wire coils needs different support compared to massive steel coils.

- V-shaped Conveyors: These are excellent for cylindrical products, keeping coils centered.

- Flatbed Conveyors: Used for very wide or heavy coils that need a stable, flat surface.

- Coil Tilters and Turnstiles: Some lines require coils to be packed horizontally, while others need vertical packing. Tilters can safely rotate a coil from horizontal to vertical or vice versa. This is crucial for optimizing storage space or preparing coils for the next stage of transport. I remember one client in Mexico who dramatically cut down on manual labor injuries after implementing an automated tilting system for their heavy rebar coils. 🇲🇽

- Centering and Positioning Units: Before wrapping, the coil needs to be perfectly centered. Automated systems use sensors (like photoelectric or laser sensors) to detect the coil’s edges and adjust its position automatically. This ensures the wrapping material is applied evenly.

Automatic Centering:Uses sensors to detect coil position and adjust conveyor speed or guides.Weight Distribution:Ensures the coil is balanced for safe rotation during wrapping.

- Wrapping Material Delivery Systems: The machine’s ability to handle different coil types also extends to the wrapping materials. It can use various films (stretch film, VCI film for corrosion protection), woven fabrics, or even paper, depending on the coil’s material and desired protection level. The tension and overlap of the wrapping material are adjustable, allowing for tailored packing. This prevents product damage, a major concern for Michael. (Coil handling versatility, automated packing solutions)

2. What Key Safety Features Are Built into Automated Coil Packing Systems?

Workplace safety is always a top priority, especially in heavy manufacturing. Manual handling of large, heavy coils poses significant risks, including crushing injuries, strains, and falls. Factory managers like Michael often face high insurance costs and employee turnover due to these hazards. The constant worry about accidents can distract from focusing on productivity.

Automated coil packing systems are engineered with multiple safety features, including comprehensive guarding, emergency stop buttons, light curtains, interlocks, and advanced sensor technologies, all designed to minimize human interaction with moving parts and heavy loads, drastically reducing the risk of workplace injuries and ensuring a safer environment for operators. These protective measures are integrated into the machine’s design to prevent accidents before they happen.

When I started FHOPEPACK, safety was a core principle. I saw too many preventable accidents in manual packing operations. Implementing automated systems is not just about efficiency; it’s about protecting your most valuable asset: your people.

Essential Safety Mechanisms in Detail

Modern packing machines are built with worker protection in mind. Here are some critical safety features:

- Physical Barriers and Guarding:

- Enclosures: Moving parts, like the wrapping ring or conveyor belts, are typically enclosed to prevent operators from accidentally touching them during operation.

- Safety Fences: These perimeter guards prevent unauthorized access to dangerous areas around the machine while it is running.

- Interlocked Gates: Access gates to the machine’s interior are often interlocked. This means the machine will automatically stop if a gate is opened, preventing entry while the equipment is active.

- Emergency Stop Systems:

- E-Stop Buttons: Strategically placed "Emergency Stop" buttons are located around the machine. Pressing one immediately cuts power to all moving parts, bringing the machine to a halt. This is a crucial last-resort safety measure.

Redundant Circuits:Many E-stop systems use redundant circuits, meaning if one part fails, another takes over to ensure the machine stops.

- Sensor-Based Safety:

- Light Curtains: These create an invisible protective barrier. If an operator breaks the light beam, the machine automatically stops. They are commonly used around access points or areas where workers might approach the machine.

- Pressure-Sensitive Mats: Placed on the floor around the machine, these mats detect if a person steps into a hazardous zone, triggering a shutdown.

- Proximity Sensors: These detect the presence of objects or people too close to moving parts, initiating a stop sequence.

- Audible and Visual Alarms:

- Warning Lights and Sirens: Before a machine starts or if an issue arises, flashing lights and audible alarms warn personnel to stay clear or indicate a problem.

- Safe Maintenance Features:

- Lock-out/Tag-out (LOTO) Points: These allow workers to safely de-energize and lock specific power sources during maintenance or repair, preventing accidental startup.

- Slow Speed Modes: For setup or troubleshooting, machines can operate at a reduced, safe speed, allowing operators to observe functions without full-speed hazards. (Automated safety features, industrial packing safety)

3. How Do Automatic Coil Packing Machines Protect Products from Damage?

Product damage during packing and handling is a significant concern for any factory manager, including Michael. Scratched surfaces, dented edges, or loose packaging lead to customer complaints, returns, and ultimately, lost profits. The traditional methods often lack the precision and consistency needed to prevent these costly issues.

Automatic coil packing machines protect products by providing consistent, secure, and gentle handling through controlled conveyor movements, precise wrapping tension, and tailored packaging materials, thereby minimizing physical impact, preventing surface abrasions, and ensuring the coil remains intact and protected from environmental factors during storage and transit. The automation eliminates the inconsistencies and potential rough handling associated with manual processes.

When I consult with clients, product integrity is always a hot topic. A well-packed coil reflects the quality of your entire operation. Investing in the right machine not only saves money on damage but also enhances your brand’s reputation.

Mechanisms for Product Protection

Automatic coil packing systems incorporate several design principles to safeguard your products:

- Gentle Handling and Conveyance:

- Controlled Acceleration/Deceleration: Coils are moved smoothly along the line, avoiding sudden jolts that could cause shifting or impact damage.

- Non-Marring Surfaces: Conveyor rollers and support surfaces are often designed with materials that prevent scratching or marking the coil’s surface. For example, some systems use rubberized coatings.

Precision Alignment:Automated alignment systems ensure coils are perfectly centered before wrapping, preventing uneven stress or accidental contact with machine parts.

- Optimized Wrapping and Strapping:

- Consistent Tension Control: The wrapping film or material is applied with precise, adjustable tension. Too little tension results in loose packaging, while too much can deform the coil or break the film. Automatic tensioning systems ensure uniformity.

- Overlap Control: Machines can be programmed for specific overlap percentages of wrapping material, ensuring full coverage and protection against dust, moisture, and corrosion. For valuable steel coils, this often includes VCI (Volatile Corrosion Inhibitor) film.

- Secure Strapping: Integrated strapping units apply steel or PET straps with controlled force, securely bundling the coil. This prevents the coil from unraveling or shifting during transport. Michael knows that a well-secured coil is essential to avoid damage during shipping.

- Material Selection and Application:

- Variety of Materials: Machines can apply multiple layers or types of packing materials, such as inner wrap, outer wrap, edge protectors, and waterproof covers, providing comprehensive protection.

- Customization: The packing sequence and materials can be customized based on the coil’s sensitivity, environmental exposure, and customer requirements.

- Automated Inspection (Optional but beneficial):

- Vision Systems: Some advanced systems include cameras or sensors to inspect the coil for defects before packing, or to verify packing quality after wrapping, further reducing the risk of damaged goods reaching customers. (Product quality protection, damage prevention)

4. What Are the Essential Steps in an Automated Coil Packing Line?

Understanding the entire process of an automated coil packing line helps managers like Michael visualize its integration into their existing operations. Without a clear picture of the workflow, it is hard to assess efficiency gains or identify potential bottlenecks. You might wonder how a raw coil transforms into a securely packed product without human hands.

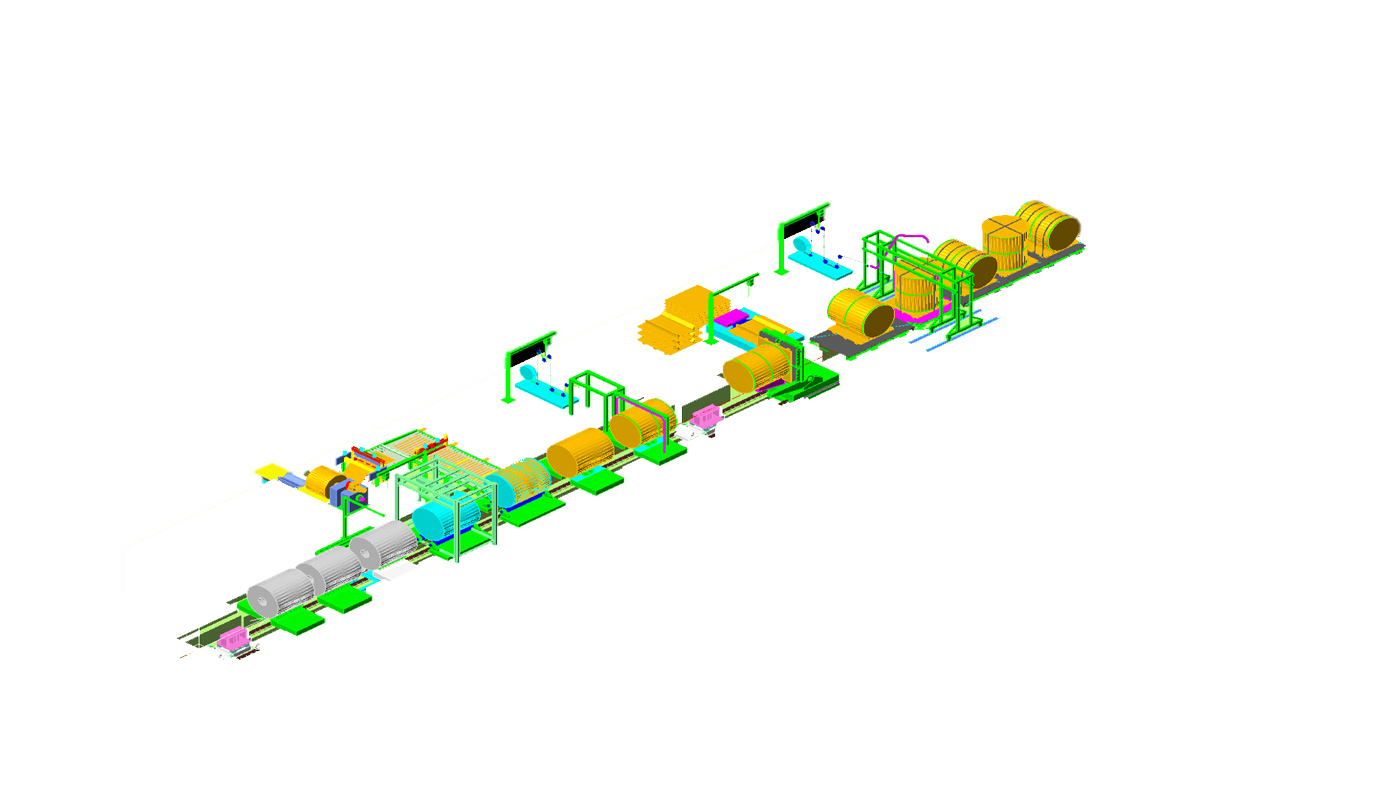

An automated coil packing line typically follows a sequence of receiving, weighing (optional), positioning, wrapping, strapping, and finally, discharge, with each step precisely controlled by a central PLC system to ensure smooth, continuous, and efficient flow, transforming raw coils into ready-to-ship packages. This integrated process eliminates manual handling between stages, ensuring consistency and speed.

My experience setting up factory lines has shown me that a well-defined process is the backbone of any efficient operation. Each step is critical, and the seamless transition between them is what truly defines an automated system.

The Automated Coil Packing Process: Step by Step

Let’s break down the journey of a coil through a typical automatic packing line:

- Coil Loading and Infeed:

- Receiving: Coils, often coming directly from a slitting or rolling line, are loaded onto the packing line’s entry conveyor. This can be done by overhead cranes, coil cars, or robotic arms, depending on the level of automation.

- Indexing: The system then indexes the coil, moving it to the correct position for the next stage.

- Weighing and Data Collection (Optional but Recommended):

- Integrated Scale: Many lines include an in-line weighing station. This automatically records the coil’s weight, which is crucial for inventory management, shipping, and quality control.

- Labeling: Data like weight, dimensions, and product ID can be automatically printed on labels and applied to the coil.

- Coil Centering and Positioning:

- Automatic Alignment: Sensors detect the coil’s exact position and guides or pushers adjust it so it is perfectly centered for wrapping. This ensures uniform packing.

- Tilting/Turning: If the packing orientation needs to change (e.g., from horizontal to vertical), a coil tilter mechanism safely rotates the coil.

- Wrapping Process:

- Film Application: The core of the packing process. A wrapping machine (often an orbital or vertical wrapper) applies multiple layers of protective film (stretch film, VCI film, paper, etc.) around the coil.

- Tension Control: Sophisticated mechanisms control the film tension, ensuring tight, wrinkle-free, and consistent wrapping.

Overlap Adjustment:Operators or the system can set the desired overlap percentage for optimal protection.- Cutting and Sealing: Once the desired number of wraps is applied, the film is automatically cut and sealed to the coil.

- Strapping and Bundling:

- Strap Feeding: After wrapping, the coil moves to a strapping station. Straps (steel or PET) are automatically fed around the coil.

- Tensioning and Sealing: The straps are tensioned to a preset force, ensuring the coil is securely bundled, then sealed using friction weld or metal seals. Multiple straps can be applied in different directions.

Preventing Unraveling:Strapping is vital for preventing coil deformation and unraveling during handling and transport.

- Discharge and Stacking:

- Exit Conveyor: The fully packed and strapped coil moves along an exit conveyor.

- Stacking/Palletizing (Optional): For further automation, robots or automated stacking systems can pick up the packed coils and place them onto pallets or into storage areas. This is where you really see the efficiency boost in logistics. (Automated production flow, packing line steps)

5. What Are the Benefits of Integrating Smart Technology in Coil Packing?

In today’s competitive manufacturing landscape, simply automating is often not enough. Factory managers like Michael are looking beyond basic mechanization. They want solutions that offer deeper insights, predictive capabilities, and seamless integration with their broader operations. The question isn’t just about how a machine works, but how it thinks and communicates.

Integrating smart technology into coil packing lines brings benefits such as real-time data monitoring, predictive maintenance, remote diagnostics, and seamless integration with factory-wide ERP systems, enabling managers to optimize performance, prevent downtime, reduce operational costs, and make data-driven decisions for continuous improvement. This transforms a mechanical process into an intelligent, responsive component of the smart factory.

When I started FHOPEPACK, the vision was always to empower businesses. Smart technology is the next frontier, giving you unprecedented control and insight. It turns potential problems into proactive solutions.

Advantages of Smart Packing Machine Integration

Smart technology elevates automated packing machines from mere tools to intelligent assets:

- Real-time Performance Monitoring and Data Analytics:

- Dashboard Interfaces: Operators and managers can access intuitive dashboards that display critical performance metrics like production rate, machine uptime, wrapping cycles, and material consumption in real time.

- Data Logging: The machine continuously logs operational data, which can be analyzed to identify trends, bottlenecks, and areas for improvement.

Operational Efficiency:Understanding these metrics helps in fine-tuning settings for maximum output and minimal waste.

- Predictive Maintenance Capabilities:

- Sensor Integration: Smart machines are equipped with sensors that monitor key component health (e.g., motor temperature, bearing vibration, film tension consistency).

- Anomaly Detection: AI-driven algorithms can detect subtle anomalies in sensor data, signaling potential component failure before it occurs.

- Reduced Downtime: This allows for scheduled maintenance, replacing parts proactively instead of waiting for a breakdown, which is crucial for a busy factory manager like Michael. Michael, from Mexico, often tells me how unexpected downtime can crush their production schedule.

- Remote Access and Diagnostics:

- Cloud Connectivity: Smart packing machines can connect to cloud platforms, allowing authorized personnel to monitor and control them remotely from anywhere.

- Remote Troubleshooting: Technicians can perform diagnostics and even adjust settings from a distance, significantly speeding up problem resolution and reducing the need for on-site visits.

Faster Support:This means quicker support from manufacturers like FHOPEPACK.

- Seamless Integration with Factory Systems:

- ERP/MES Integration: Smart packing lines can communicate directly with a factory’s Enterprise Resource Planning (ERP) or Manufacturing Execution System (MES).

- Automated Data Flow: This enables automated order processing, inventory updates, and production scheduling, eliminating manual data entry and reducing errors.

- Optimized Supply Chain: A fully integrated system helps optimize the entire supply chain, from raw material to finished goods.

- Enhanced Customization and Flexibility:

- Recipe Management: Smart HMIs (Human-Machine Interfaces) allow operators to store and quickly recall packing "recipes" for different coil types, simplifying changeovers and ensuring consistent quality.

- Adaptive Control: Advanced algorithms can adapt machine parameters in real-time based on detected coil characteristics or production requirements, ensuring optimal performance across diverse products. (Smart factory integration, predictive analytics)

Conclusion

Automatic coil packing machines transform factory operations by enhancing efficiency, safety, and product quality through intelligent automation. They offer robust solutions for various coil types and sizes, integrating smart technology for data-driven optimization. Investing in a reliable steel coil packing line like those from FHOPEPACK, empowers businesses to meet modern industrial demands.