How a Steel Coil Packing Machine Works — Process and Components?

Manufacturing operations today face many pressures. You might be struggling with bottlenecks, high labor costs, or the constant worry of product damage during handling. These issues can slow down your entire production line and eat into your profits. I understand these challenges very well, having spent years building a packing machine factory from the ground up.

A steel coil packing machine automates the complex task of wrapping and securing heavy steel coils, using specialized processes and robust components to protect products, improve efficiency, and enhance workplace safety. It moves coils, applies protective materials like stretch film or steel strips, and then secures them for storage or transport, making the entire end-of-line process faster and more reliable than manual methods.

Understanding how these machines work is not just about technical knowledge; it is about finding real solutions for your factory. Let us dive deeper into the world of steel coil packing and see how these systems can transform your operations.

1. What is a Steel Coil Packing Machine and Why is it Essential for Modern Factories?

Are you still relying on manual labor for packing heavy steel coils? This approach can create a lot of problems. It often leads to slow production, high risks of injury, and inconsistent packaging quality. These issues directly impact your bottom line and your team’s safety.

A steel coil packing machine is an industrial system designed to automatically wrap and secure large, heavy coils of steel or other metals. It applies various protective layers like stretch film, paper, or steel strapping, ensuring the coils are safe from damage, moisture, and dust during storage and transportation. This automation is essential for modern factories because it boosts throughput, drastically improves worker safety, reduces material waste, and delivers consistent, high-quality packaging.

From my experience in the packing machine industry, I have seen first-hand how much difference the right equipment makes. Factories, especially those dealing with heavy steel coils, need more than just a machine; they need a solution that stands up to demanding environments. Modern factories are constantly pushing for higher productivity and lower costs. Manual packing is simply not sustainable. It is slow, prone to errors, and puts workers at risk. An automated system changes the game by handling heavy lifting and repetitive tasks. This frees up your workforce for more skilled jobs. It also means you can process more coils in less time. This directly impacts your delivery schedules and customer satisfaction. The consistency of machine packing also means fewer damaged products. This saves money from returns or rework. Many clients I have helped over the years found that investing in these machines was not just an expense. It was a strategic move that brought significant returns on investment. It is about making your factory smarter, safer, and more profitable. (Automated steel coil packaging, industrial efficiency, workplace safety solutions)

The Role of Steel Coil Packing in Logistics and Supply Chain

Modern factories operate within complex supply chains. The journey of a steel coil from production to the end-user involves multiple stages of handling and transport.

- Protection Against Damage: Coils are heavy and can be easily damaged by impacts, abrasion, or moisture. Proper packing protects edges, surfaces, and ensures structural integrity.

- Ease of Handling: Well-packaged coils are easier to lift, stack, and move with forklifts or cranes. This speeds up loading and unloading operations.

- Compliance and Standards: Many industries have strict packaging standards. Automated systems ensure these standards are consistently met.

- Reduced Product Loss: Fewer damaged coils mean less scrap, fewer rejections, and happier customers. This directly improves your profitability.

Key Benefits of Automation in Heavy Duty Packing

| Benefit | Manual Packing Risks | Automated Solution | Impact on Factory Operations |

|---|---|---|---|

| Increased Efficiency | Slow process, production bottlenecks | High speed, continuous operation | Faster throughput, reduced delivery times, higher output |

| Enhanced Safety | High risk of worker injury from heavy lifting | Minimized human contact with heavy coils | Fewer accidents, lower insurance costs, improved worker morale |

| Consistent Quality | Variable packaging quality, human error | Uniform wrapping tension and coverage | Fewer product damages, reduced customer complaints |

| Cost Reduction | High labor costs, material waste, product loss | Optimized material usage, reduced rework | Lower operational expenses, improved profit margins |

| Operational Scalability | Limited by workforce availability and speed | Adapts to varying production volumes | Flexibility to meet fluctuating market demands |

2. What are the Core Processes Involved in Automatic Steel Coil Packing?

The thought of switching from manual to automatic packing can feel like a big step. You might worry about the complexity, the learning curve, or how it will fit into your existing production line. I have seen these concerns many times. But the process is often more streamlined than you think.

Automatic steel coil packing involves a series of integrated steps: first, the coil is precisely positioned; then, protective layers like stretch film, paper, or woven fabric are applied tightly around its circumference and eye; finally, strapping or banding secures the package. This sequence ensures comprehensive protection for the coil while significantly speeding up the overall packing operation and reducing manual effort.

When I first started building my packing machine factory, I knew that understanding the flow of materials was key. It is not just about individual machines; it is about how they work together seamlessly. For automatic steel coil packing, each step builds on the last. It ensures that the coil is fully protected from start to finish. This process often begins right after the coiling line. The hot coil moves to a cooling area, then proceeds to the packing stage. The goal is to minimize human interaction with the heavy, often hot, coils. This drastically reduces safety risks. Each stage is automated, controlled by a central system. This ensures precision and consistency that manual methods simply cannot match. From my perspective, a well-designed packing process is critical for any high-volume metal processing plant. It is what transforms raw coils into safely packaged products ready for the market. (Automatic coil packaging steps, industrial packing process, material handling automation)

Detailed Steps in a Typical Coil Packing Sequence

Understanding each step helps in optimizing your entire end-of-line process.

2.1 Coil In-feeding and Positioning 🎯

- Action: The finished steel coil is transported from the production line to the packing area. This often happens via a coil car, conveyor system, or walking beam.

- Purpose: To place the coil precisely in the center of the packing machine’s rotating platform or wrapping station. Accurate positioning is vital for uniform wrapping.

- Technology: Sensors (photoelectric, proximity) ensure correct alignment.

- Why it matters for Michael: This is where the manual handling bottleneck and safety risk for heavy coils are eliminated.

2.2 Eye-to-OD/ID Wrapping (If Applicable) 🔄

- Action: For some coils, especially those prone to internal damage, an inner wrap might be applied first. The machine wraps material through the eye (inner diameter) of the coil and around the outer diameter (OD).

- Purpose: Provides comprehensive protection against dust, moisture, and impact from both inside and out.

- Materials: Often stretch film, paper, or VCI (Volatile Corrosion Inhibitor) paper.

2.3 Outer Circumferential Wrapping 🌀

- Action: A rotating arm or turntable wraps the outer surface of the coil with protective material. This is usually the main wrapping stage.

- Purpose: To create a tight, multi-layered barrier against physical damage, corrosion, and environmental factors.

- Materials: Stretch film, plastic film, PE film, woven fabric, or waterproof paper. Tension control systems ensure a snug fit.

- Why it matters for Michael: This step directly addresses product loss from damage during transport and storage.

2.4 Strapping/Banding ⛓️

- Action: Steel or PET straps are applied around the coil, typically at multiple points, and then tensioned and sealed.

- Purpose: To secure the wrapping material, prevent the coil from unwinding, and keep the package tight and stable.

- Technology: Automatic strapping heads tension and weld/crimp straps.

- Why it matters for Michael: Ensures package integrity, preventing coils from shifting or unwrapping, which is critical for safety and product stability during shipping.

2.5 Labeling and Discharge 🚚

- Action: A label with product information (weight, batch number, destination) is applied. The packed coil is then moved off the machine onto a conveyor or storage area.

- Purpose: For inventory management, logistics tracking, and final delivery.

- Technology: Automatic label applicators, conveyor systems, or automated guided vehicles (AGVs).

3. What Key Components Make Up an Efficient Steel Coil Packing System?

When you consider investing in a new packing machine, you might only think of the overall unit. But understanding the individual components is critical. It helps you assess quality, durability, and maintenance needs. A robust system is not just about fancy features. It is about reliable parts that work together without fail.

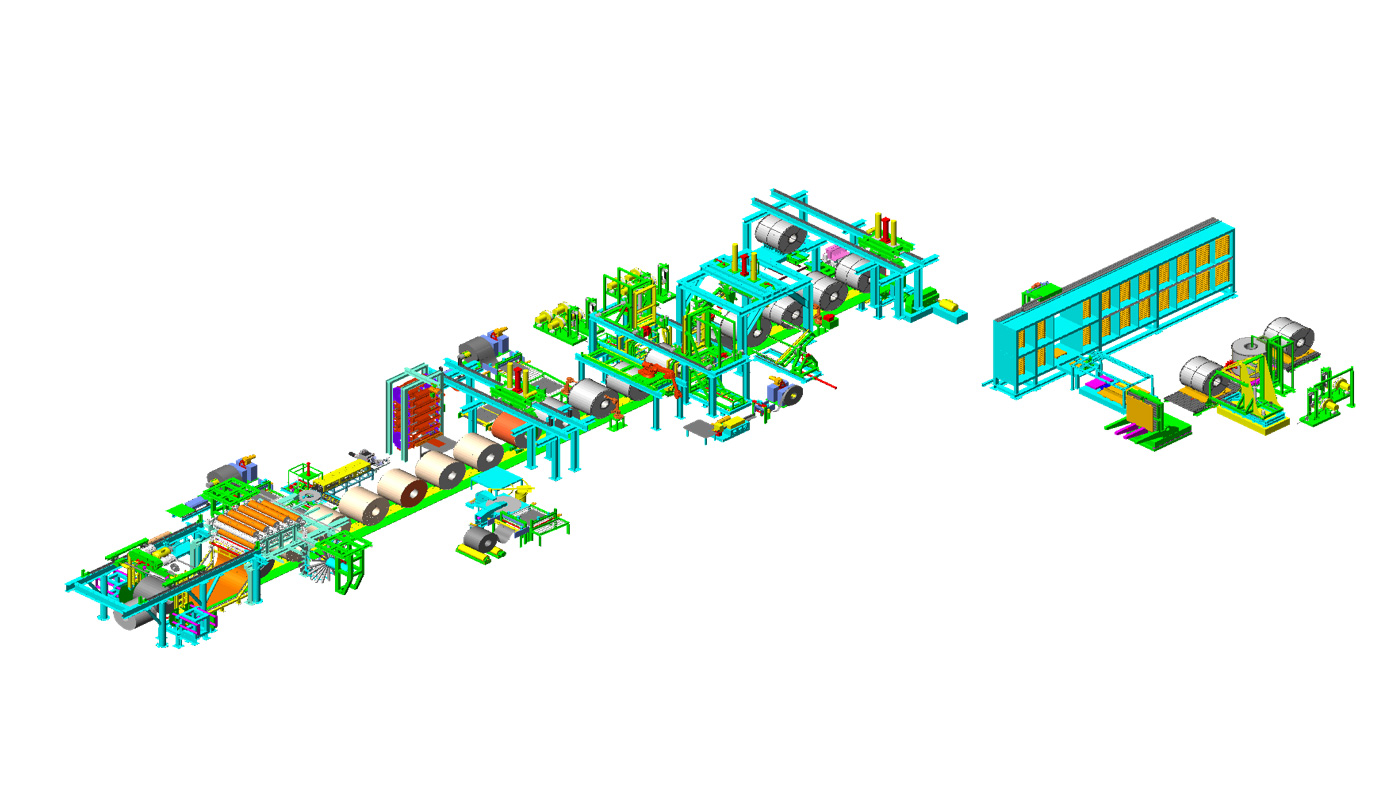

An efficient steel coil packing system is built from several key components working in harmony: a heavy-duty coil conveyor or loading system, a robust wrapping machine (often with an orbital wrapper or turntable), a precise strapping unit, and a centralized control system. Other vital parts include tensioning devices, material dispensers, and safety mechanisms. Each component plays a crucial role in ensuring smooth operation, consistent packaging quality, and maximum uptime for industrial use.

From my early days working at a packing machine factory, I quickly learned that the strength of a system lies in its parts. You can have the best concept, but if the components are weak, the whole system fails. This is especially true for packing heavy steel coils. These machines need to withstand immense weight and continuous operation in tough factory conditions. I always focus on robust construction and high-quality materials. This ensures longevity and minimizes downtime. When I established my own factory, this principle guided every design decision. We used industrial-grade motors, durable steel frames, and reliable sensors. These choices directly impact the machine’s performance and maintenance costs. For a factory manager like Michael, knowing these components helps you ask the right questions when buying. It ensures you get a machine that truly supports your operational goals for years to come. (Heavy duty packing machine components, industrial equipment parts, automated packaging technology)

Essential Components of a Steel Coil Packing Machine

| Component | Function | Importance for Coil Packing | Potential Issues with Low-Quality |

|---|---|---|---|

| Coil Conveyor/Loading System | Transports coils to and from the packing station. Can be a V-conveyor, chain conveyor, or coil car. | Ensures safe and automated handling of heavy coils, prevents manual lifting. | Coil misalignment, jams, damage to coil or machine. |

| Wrapping Head/Orbital Wrapper | Rotates around the coil, dispensing and applying wrapping material (film, paper, fabric). | Critical for uniform and tight application of protective layers. | Uneven wrapping, material breakage, poor protection. |

| Material Dispenser Units | Holds and feeds the wrapping material (film rolls, paper rolls) to the wrapping head. | Ensures continuous material supply and consistent tension. | Frequent material changes, inconsistent wrap, downtime. |

| Automatic Strapping Unit | Feeds, tensions, seals, and cuts strapping material (steel or PET) around the coil. | Provides critical security, preventing coils from unwinding or shifting. | Loose straps, failed seals, package instability. |

| Tension Control System | Regulates the tightness of the wrapping material during application. | Ensures snug fit, prevents material breakage, and protects product. | Loose wraps, film tearing, insufficient protection. |

| PLC Control System (HMI) | The "brain" of the machine, managing all operations, safety interlocks, and diagnostics. | Centralized control, easy operation, diagnostics, and troubleshooting. | Complex operation, frequent errors, difficult to diagnose faults. |

| Safety Guarding & Sensors | Physical barriers and electronic sensors to prevent accidents during operation. | Protects operators from moving parts and ensures a safe working environment. | Risk of injury, non-compliance with safety regulations. |

| Hydraulic/Pneumatic Systems | Powers movements like clamping, lifting, or tensioning. | Provides the necessary force and controlled motion for heavy-duty tasks. | Leaks, inconsistent power, operational failures. |

4. How Does Automation in Coil Packing Address Common Manufacturing Challenges?

Many factory managers I speak with face similar pressures. They need to boost output, cut costs, and keep their workers safe. Relying on outdated or manual packing methods often makes these goals harder to reach. You might feel stuck between the need to upgrade and the fear of a complex transition.

Automation in steel coil packing directly addresses common manufacturing challenges by significantly increasing operational efficiency through faster throughput and reduced labor needs. It enhances workplace safety by eliminating hazardous manual handling of heavy coils, and it drastically cuts product loss by providing consistent, damage-resistant packaging. This holistic approach ensures factories can meet their production targets, reduce operational costs, and maintain high product quality, transforming bottlenecks into streamlined processes.

I know these challenges intimately. When I was an employee in a packing machine factory, I saw how much effort went into manual tasks. Later, as a factory owner, I learned that efficiency and safety were not just ideals; they were necessities for survival and growth. This is why I am so passionate about sharing knowledge. Automation is not just about buying a machine. It is about investing in a solution that solves real-world problems. For example, a factory manager like Michael in Mexico, overseeing metal processing, constantly grapples with efficiency bottlenecks at the end of the line. Manual wrapping of heavy steel coils is slow, prone to errors, and carries huge risks for workers. An automated system takes over these demanding tasks. This means faster processing times and fewer incidents. It also means your valuable products are consistently protected. This reduces customer complaints and improves your brand’s reputation. It is a win-win for everyone involved. (Manufacturing operational challenges, automated solutions, industrial efficiency improvement)

Addressing Michael’s Challenges with Automated Packing

Let’s look at how automated coil packing provides direct solutions to the specific challenges faced by factory managers like Michael.

🛠️ Efficiency Bottlenecks:

- Challenge: Manual steel coil and wire packing processes are slow and inefficient, impacting overall production and delivery speeds.

- Automated Solution: High-speed automatic wrapping and strapping machines can process coils much faster than manual labor. Conveyor systems ensure a continuous flow.

- Impact: Production throughput increases dramatically. Deliveries become more reliable. The entire end-of-line process is no longer a choke point.

🚧 Safety Hazards:

- Challenge: Manual handling of heavy molds or flipping pallets is inefficient and poses high risks of injury, leading to high insurance costs and employee turnover.

- Automated Solution: Machines handle all heavy lifting, rotating, and strapping. Workers operate from a safe distance. Coil cars and conveyors move coils.

- Impact: Significant reduction in workplace accidents and injuries. Lower insurance premiums. Improved employee morale and retention due to a safer work environment.

💰 Product Loss:

- Challenge: Products (like steel coil edges) are often damaged during internal transfer and packing, leading to customer complaints and lost profits.

- Automated Solution: Consistent, tight, and multi-layered wrapping protects coils from external damage, moisture, and dust. Automated handling minimizes physical contact.

- Impact: Fewer damaged products, reduced rework, and lower scrap rates. Improved product quality leads to higher customer satisfaction and increased profitability.

✅ Supplier Trust Crisis:

- Challenge: Past experiences with equipment suppliers who only focused on sales, with poor after-sales service, make finding new partners very cautious.

- Automated Solution: By working with a knowledgeable partner like FHOPEPACK, founded on expertise and dedicated to long-term support, factories gain a reliable partner.

- Impact: Builds trust through expert guidance, proven solutions, and commitment to after-sales support. This ensures the investment truly solves problems and drives business growth.

5. How Can You Choose the Right Steel Coil Packing Machine for Your Operations?

You know the benefits of automation. Now comes the critical part: selecting the right machine. This is not a decision to take lightly. You might worry about making the wrong choice, investing in equipment that does not fit your specific needs, or ending up with poor after-sales support. I have seen how these concerns can delay crucial upgrades.

Choosing the right steel coil packing machine involves a careful evaluation of your factory’s specific production volume, coil dimensions, desired packing materials, and budget. It is essential to partner with a supplier who offers not just equipment, but deep industry expertise and reliable after-sales support. Look for machines with proven durability, advanced safety features, and a clear return on investment. Prioritize a vendor who acts as a true consultant, understanding your challenges and offering tailored solutions rather than just selling a product.

My journey from an employee to a factory owner taught me the immense value of understanding a client’s specific context. It is never a one-size-fits-all solution. When clients approach FHOPEPACK, I do not just recommend a machine. I take the time to understand their production bottlenecks, their safety concerns, and their efficiency goals. For someone like Michael, running a metal processing plant in Mexico, the machine must be tough enough for heavy industry. It must be efficient enough to handle high volumes, and it must integrate smoothly into existing lines. I always advise looking beyond the initial price tag. Consider the long-term operational costs, maintenance requirements, and the supplier’s reputation for support. A machine that breaks down often, or a supplier who disappears after the sale, will cost you far more in the long run. My mission at FHOPEPACK is to share knowledge that helps you make informed decisions. We want to empower you to choose solutions that genuinely drive your business forward. (Coil packing machine selection, industrial equipment investment, reliable packaging solutions)

Key Considerations for Selecting Your Steel Coil Packing System

Making the right choice for your factory requires a clear understanding of your needs and the market offerings.

5.1 Assess Your Specific Needs 📝

- Coil Dimensions: What are the typical outer diameter (OD), inner diameter (ID), and width of your coils? Machines are designed for specific ranges.

- Production Volume: How many coils do you need to pack per hour or per shift? This determines the required speed and automation level.

- Packing Material: What type of protective material do you need (stretch film, paper, woven fabric, VCI film, steel strapping, PET strapping)?

- Integration: How will the packing machine fit into your existing production line? Does it need to connect with an upstream coiler or a downstream storage system?

5.2 Prioritize Durability and Reliability 💪

- Heavy-Duty Construction: For steel coils, the machine must be built robustly to withstand heavy loads and continuous operation. Look for solid steel frames and high-quality components.

- Component Quality: Inquire about the brand of motors, gearboxes, electrical components (e.g., Siemens, Schneider, Allen-Bradley). These impact longevity and ease of maintenance.

- Proven Track Record: Choose suppliers with a long history and positive testimonials, especially from factories with similar operational demands.

5.3 Evaluate Safety Features 🛡️

- Guarding: Ensure all moving parts are properly guarded to prevent operator access during operation.

- Emergency Stops: The machine should have easily accessible emergency stop buttons at multiple points.

- Safety Sensors: Look for light curtains, safety mats, or interlocks that immediately stop the machine if an operator enters a danger zone.

- Compliance: Confirm that the machine meets relevant international safety standards (e.g., CE, OSHA).

5.4 Calculate Return on Investment (ROI) 📊

- Cost Savings: Estimate savings from reduced labor, decreased product damage, and optimized material usage.

- Increased Throughput: Quantify the value of increased production capacity.

- Maintenance and Consumables: Factor in the ongoing costs of replacement parts and packaging materials.

- Long-Term Value: Consider how the investment supports your growth and competitiveness over several years.

5.5 Choose the Right Partner, Not Just a Vendor 🤝

- Expertise: Look for a supplier who understands your industry, your specific challenges, and can offer informed advice.

- After-Sales Support: What kind of installation, training, spare parts, and technical assistance do they provide? A reliable partner ensures your machine keeps running.

- Customization: Can they adapt the machine to your unique requirements or factory layout?

- Trust: Based on my experience, companies like Fengding are leaders in the field, known for robust solutions and strong support. Wuxi Buhui also offers reliable options. We at FHOPEPACK pride ourselves on sharing knowledge and delivering solutions that truly help businesses grow.

Conclusion

Understanding how a steel coil packing machine works, from its process to its components, is key to optimizing your factory. These machines boost efficiency, enhance safety, and protect your products. Choosing the right steel coil packing line transforms challenges into opportunities for growth.