Horizontal vs Vertical Steel Coil Packing System — Which Layout Fits Best?

Are you a factory manager in the heavy industry, perhaps in Mexico, dealing with the constant pressure of production bottlenecks, safety concerns, and rising costs? I know the struggle. I have seen firsthand how inefficient manual packing for steel coils and wire can slow everything down. It causes delays, risks worker injury, and even damages your valuable products. This not only frustrates clients but also eats into your profits. You are looking for reliable solutions, not just another machine. You need equipment that can handle your tough environment and a partner who truly understands your factory’s needs.

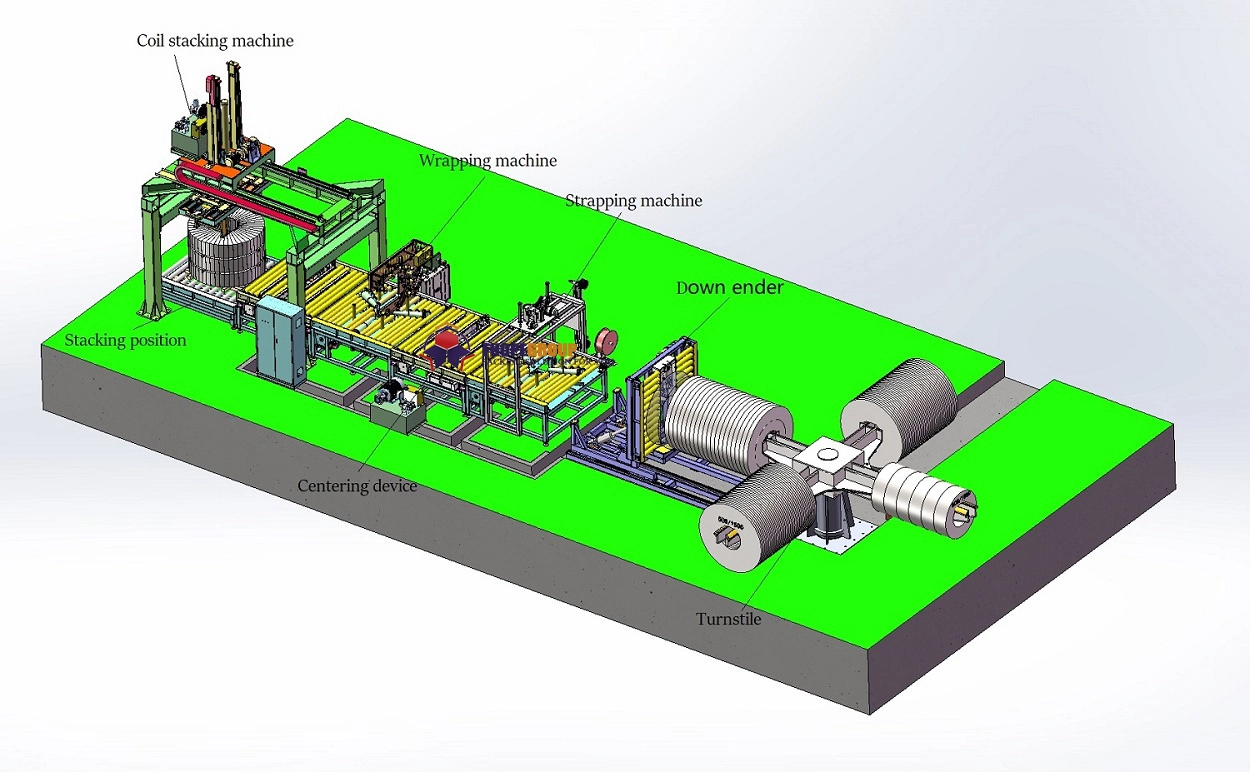

Choosing the right steel coil packing system, whether horizontal or vertical, is a critical decision. There is no one-size-fits-all answer. The best layout for your factory depends entirely on your specific product type, available floor space, required production speed, and safety priorities. Both systems offer unique advantages, and understanding these differences is key to optimizing your operations and achieving your goals for efficiency and safety.

Making the wrong choice can lead to more problems than it solves. But with the right knowledge, you can transform your end-of-line processes. Let’s dive deeper into these two main types of packing systems. We will explore their features, benefits, and the situations where each system truly excels. This will help you make an informed decision for your business.

1. What Are Horizontal and Vertical Coil Packing Systems?

Do you sometimes feel overwhelmed by the technical jargon in the packing machine world? Many factory managers, like Michael Chen in Mexico, just want to know what these systems actually do. They need to understand the core differences without getting lost in complex details. What exactly sets a horizontal system apart from a vertical one in a steel coil factory?

Horizontal and vertical coil packing systems refer to the orientation of the coil during the wrapping process. A horizontal system wraps the coil while it lies on its "eye to the sky" or "eye to the side." A vertical system wraps the coil while it stands upright, with its flat sides facing the wrapping mechanism. Each method is designed to handle coils differently, offering distinct advantages for various applications and factory layouts.

Let me explain this simply. From my years working in and then building packing machine factories, I learned that understanding the basics is vital. It helps you see how each system fits into your overall production line. This understanding will empower you to identify bottlenecks and see how automation can provide a real solution, cutting labor costs, and reducing damage to your products.

Horizontal Coil Packing

Imagine your steel coils are lying flat, like a stack of pancakes. A horizontal packing machine wraps the coil around its circumference while it stays in this position. This setup is common for many types of coils.

- How it works: The coil moves into the machine on a conveyor or trolley. The wrapping material (stretch film, VCI paper, woven fabric) then goes around the coil as it rotates. The wrapping head moves horizontally around the coil.

- Key Features:

- Coil remains horizontal during wrapping.

- Often integrated with existing conveyor systems.

- Can handle a wide range of coil sizes and weights.

Vertical Coil Packing

Now, imagine your steel coils standing upright, like a giant toilet paper roll. A vertical packing machine wraps the coil in this position. This is often used for specific needs, especially when floor space is tight or certain protection is required.

- How it works: The coil is placed upright on a rotating platform. The wrapping arm moves vertically around the coil, applying the material.

- Key Features:

- Coil stands vertically during wrapping.

- Takes up less floor space compared to some horizontal setups.

- Often good for small to medium-sized coils.

Why Does Orientation Matter?

The orientation of the coil during packing directly impacts several things:

- Safety: Moving heavy coils safely is a major concern. Different orientations have different handling risks.

- Efficiency: How quickly coils can be loaded, wrapped, and unloaded changes with the system type.

- Space: Some factories have limited floor space. The system’s footprint is very important.

Understanding these basic differences is the first step. It allows us to move on to more specific benefits and challenges of each system. This will help you decide which one will best solve your plant’s issues, like reducing product loss during internal transfer and meeting strict safety regulations. (packing machine basics, coil orientation importance, factory operation efficiency)

2. When Does a Horizontal System Shine for Your Coils?

Are your current steel coil packing methods slow and heavily manual? Is your factory struggling with bottleneck issues at the end of the production line? Many factory managers, especially in places like Mexico, face these exact problems. They often wonder if a horizontal packing system can really make a difference. What situations make a horizontal layout the clear winner for packing efficiency and safety?

A horizontal steel coil packing system truly shines when you need high-speed, continuous wrapping for coils that are already oriented horizontally during production or storage. It is ideal for facilities with ample floor space and existing conveyor lines. This system provides consistent, robust wrapping, especially for larger or heavier coils, while minimizing manual handling. This helps to reduce worker injury risks and product damage during the packing process.

I have helped many clients, including those with operations similar to a metal processing plant in Mexico, integrate horizontal systems. These clients often see significant improvements in throughput and a sharp drop in product damage. The key is understanding when this system aligns perfectly with your existing workflow and product characteristics. It is not just about buying a machine. It is about investing in a solution that integrates seamlessly and solves your real production problems.

Advantages of Horizontal Coil Packing

Horizontal systems offer several compelling benefits, particularly for specific types of operations.

- Streamlined Integration with Production Lines:

- Many slitting or forming lines naturally produce coils in a horizontal orientation. A horizontal packing machine can directly receive these coils. This means less need for re-orientation. This saves time and reduces potential for damage. This direct flow improves overall production efficiency.

- Think about a continuous steel processing line. Coils move along conveyors. A horizontal wrapper fits right into this flow. This creates a smooth, automated end-of-line process. This is important for managers who need to boost output and cut costs.

- Superior Stability and Wrapping Quality for Large Coils:

- Large, heavy steel coils are inherently more stable when lying flat. This makes them easier and safer to handle during the wrapping process. The horizontal wrapping method provides uniform tension across the entire surface. This results in a tighter, more protective wrap.

- This robust packaging prevents product damage, like bent edges, during transport and storage. Reducing customer complaints is a major goal for factory managers like Michael. This directly impacts profitability.

- Enhanced Safety and Reduced Manual Intervention:

- With horizontal systems, coils are often conveyed directly into the wrapper. This significantly minimizes the need for forklifts or overhead cranes to reposition coils for packing. Fewer manual moves mean less risk of accidents. It also reduces strain injuries for workers.

- This is a big step towards improving worker safety. It also helps reduce insurance costs. It helps retain valuable employees. This directly addresses the safety concerns factory managers often face. This is a clear path to a safer workplace. (horizontal packing benefits, large coil handling, production line integration, worker safety solutions)

3. When is a Vertical System the Superior Choice for Your Plant?

Is your factory constantly battling with limited floor space? Are you dealing with smaller, specialized coils that need very specific protection? Many factory managers, even in growing industrial areas like Mexico, find themselves in this exact situation. They might wonder if a vertical packing system is the answer to their unique production challenges. When does going vertical make more sense for your specific packing needs?

A vertical steel coil packing system is often the superior choice when factory floor space is a premium, and you are handling smaller to medium-sized coils. It also excels when specific protection for the coil’s flat surfaces is critical. This layout offers greater flexibility for various handling methods and can integrate well into more compact production areas. It provides efficient and safe wrapping solutions where space constraints or specialized product care are primary concerns.

During my journey from a packing machine employee to building FHOPEPACK, I have seen factories where space was the biggest hurdle. Sometimes, a vertical system was the only practical way to introduce automation. It delivered significant improvements in safety and efficiency, even in tight spaces. It is about finding the right fit for your factory, not just choosing the most common option.

Advantages of Vertical Coil Packing

Vertical systems bring distinct benefits, especially for factories with particular space or product needs.

- Optimized Floor Space Utilization:

- For factories with compact layouts, a vertical packing machine is a game-changer. It requires a smaller footprint compared to many horizontal setups. This is because the coil stands upright during wrapping. This leaves more valuable floor space free for other operations or storage.

- This is crucial for managers in older or smaller facilities trying to modernize. It allows for automation without needing costly factory expansions. It helps maximize existing resources.

- Enhanced Protection for Coil Sides and Specific Handling Needs:

- When coils are wrapped vertically, the flat sides are naturally presented to the wrapping mechanism. This allows for excellent protection of these critical surfaces. This is important for products where surface quality is paramount. It also offers more flexibility for specific strapping or banding needs during packing.

- This method can reduce damage to delicate edges or surfaces. This leads to fewer customer complaints and better product integrity. This is a direct answer to challenges like product damage during internal transfer.

- Versatility in Loading and Unloading:

- Vertical systems can often accommodate various loading and unloading methods. This includes overhead cranes or specialized floor-level conveyors. This versatility makes them adaptable to different material handling setups within a factory.

- This adaptability is valuable for managers looking for flexible solutions. It helps them to upgrade their current equipment. It ensures a smooth transition to automated packing. This supports their goal of increasing automation and reducing manual handling for safety. (vertical packing benefits, space efficiency, coil side protection, flexible material handling, automation in tight spaces)

4. Making the Right Choice for Your Factory: Key Considerations?

As a factory manager, your main goals are likely increasing output, controlling costs, and keeping your team safe. The thought of investing in new packing equipment can be daunting. You need a solution that truly solves your problems, not one that creates new ones. How do you decide between a horizontal and vertical coil packing system to best meet your factory’s specific demands, especially when considering ROI and long-term partnership?

Making the right choice between a horizontal and vertical steel coil packing system requires a careful evaluation of several key factors: your existing factory layout, the physical characteristics of your coils, your desired production throughput, and your budget for both initial investment and operational costs. The best system will provide a clear return on investment (ROI) by enhancing safety, boosting efficiency, and reducing product loss. Partnering with an expert who understands these nuances is crucial for a successful implementation.

My experience running and building packing machine factories showed me that every factory is unique. There is no magic bullet. The decision needs to be strategic. It must align with your long-term goals. It also needs to provide tangible benefits for your operations. This is about more than just buying a machine. It is about finding a solution that drives your business forward.

Evaluate Your Production Environment

Before making any decision, look closely at your factory.

- Existing Layout and Space Constraints:

- How much floor space is available for a new packing line? Vertical systems typically need less floor area. Horizontal systems might integrate better with long, straight production lines. Map out your current material flow. Identify any bottlenecks. This helps visualize where each system might fit.

- Consider future expansion plans. Will the chosen system still be efficient if your production volume grows? A good solution now should also work for tomorrow.

- Coil Characteristics (Size, Weight, Material):

- What are the typical dimensions and weights of the coils you process? Horizontal systems often handle larger, heavier coils with ease. Vertical systems are usually better for smaller to medium-sized coils. What kind of material are your coils made of? Does it require special handling or protection?

- Different materials might have specific wrapping needs to prevent surface damage. Choose a system that can effectively protect your specific product range.

Assess Your Operational Priorities

Your business goals should guide your equipment choice.

- Safety Requirements and Manual Handling Reduction:

- A primary concern for any factory manager is worker safety. Analyze where manual handling risks are highest in your current packing process. Both automated horizontal and vertical systems reduce manual labor significantly. However, one might offer greater safety improvements based on your specific coil types and existing handling methods.

- Look for systems that minimize the need for forklifts or overhead crane movements for packing. This reduces accident potential and lowers injury claims.

- Desired Throughput and Automation Level:

- How many coils do you need to pack per hour or shift? What level of automation are you aiming for? Some systems offer higher throughput rates. Others are more suited for semi-automated operations. Define your target efficiency.

- Consider integration with upstream and downstream processes. A fully automated line will reduce labor costs and increase speed. This is a key goal for driving down overall expenses.

Consider Long-Term Investment and Partnership

This is where my experience with FHOPEPACK truly comes into play.

- Return on Investment (ROI) and Cost Analysis:

- Beyond the initial purchase price, look at the total cost of ownership. This includes energy consumption, maintenance, spare parts, and labor savings. A clear ROI calculation is essential. How quickly will the investment pay for itself through increased efficiency, reduced product damage, and lower labor costs?

- Don’t forget the cost of lost production due to downtime. Invest in reliable equipment that offers long-term value.

- Supplier Expertise and After-Sales Support:

- This is critical. As a factory manager, you need a partner, not just a seller. You want a supplier who understands your industry, your specific challenges (like those in the Mexican market), and can provide expert advice. A good supplier offers strong after-sales service, spare parts availability, and technical support.

- Michael’s past experience with unreliable suppliers highlights this need. Look for a partner with deep industry background, like FHOPEPACK, who can offer real solutions and support your business growth. (factory layout analysis, coil size considerations, safety automation, ROI calculation, reliable supplier, production efficiency goals)

My Insights

From my journey, starting as an employee and then building FHOPEPACK, I have learned one major thing: the best packing solution is always the one tailored to your specific needs. Many suppliers just want to sell you a machine. But I believe in sharing knowledge and offering solutions. This is why FHOPEPACK is more than just a brand.

For factory managers like Michael Chen, choosing between horizontal and vertical is not just a technical decision. It is a strategic one. It impacts your team’s safety, your product quality, and your bottom line. I have seen how the right system can transform a struggling production line into a highly efficient and safe operation. I also know the frustration of dealing with systems that do not fit, or suppliers who disappear after the sale.

My advice is simple: look for a partner who takes the time to understand your unique challenges. This means someone who will consider your existing factory layout, the specific types of steel coils you produce, your throughput goals, and your budget. They should offer solutions that show a clear return on investment. This includes reducing manual handling, increasing safety, and minimizing product damage. At FHOPEPACK, our goal is to empower you with the right knowledge and the best equipment to succeed. We focus on providing reliable systems and being a trustworthy long-term partner for your business.

Conclusion

Choosing the right coil packing system means boosting safety and efficiency. Consider your factory’s specific needs and partner with experts for optimal steel coil packaging line solutions.