Global Market Comparison 2025 | Leading steel Coil Packing Line Manufacturers Worldwide

Working in the packing machine industry for decades, I have seen firsthand how much impact efficient and reliable equipment has on a factory’s success. Many plant managers, like Michael Chen in Mexico, face immense pressure to boost output, control costs, and keep workers safe. I started FHOPEPACK because I believe sharing knowledge can help solve these exact problems. If you’ve ever felt the pinch of slow manual processes or worried about worker safety, you know what I am talking about.

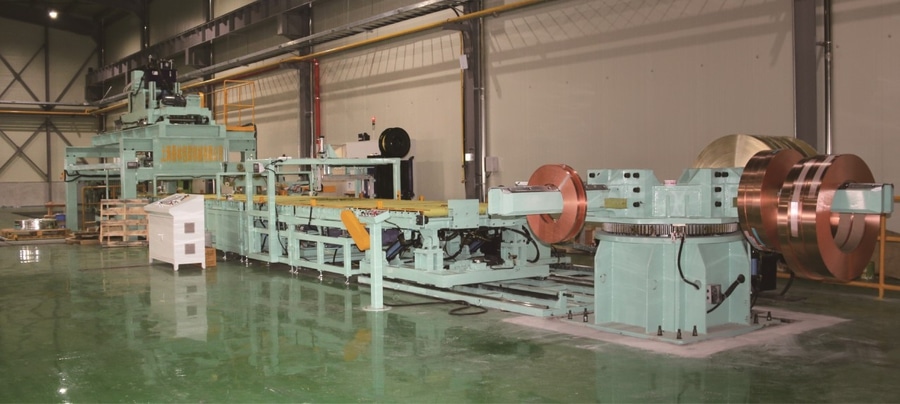

When we look at the global market for steel coil packing lines in 2025, leading manufacturers are defined by their innovation, robust engineering, and a deep understanding of customer needs, offering solutions that prioritize automation, safety, and long-term operational efficiency.

The world of steel coil packing is constantly evolving. Staying ahead means understanding who the key players are and what drives their success. Let’s dive deeper into the landscape of global steel coil packing line manufacturers and what makes them stand out in the competitive market of 2025.

1. What defines a leading steel coil packing line manufacturer in today’s market?

Have you ever wondered what truly separates a good packing machine supplier from a great one? For years, I’ve navigated this industry, from working on the factory floor to building my own successful packing machine plant. I’ve seen countless equipment promises, but only a few truly deliver. The stakes are high; a wrong choice can cost you dearly in downtime and lost production.

In today’s market, a leading steel coil packing line manufacturer is defined by their unwavering commitment to innovation, machine reliability, comprehensive after-sales support, and the ability to customize solutions that directly address complex operational challenges and improve safety standards.

When I think about what makes a manufacturer truly ‘leading,’ it goes beyond just selling a machine. It’s about understanding the core problems factory managers like Michael face every day: efficiency bottlenecks, safety hazards, and product damage. My journey taught me that a great partner offers solutions, not just products. This means having equipment that can withstand the harsh environments of a metal processing plant and having a team that knows how to troubleshoot and support you for years to come. It is about an investment that pays off. They focus on automation to cut down on manual labor, which directly reduces injury risks and speeds up your production line. They also design systems to protect your valuable steel coils from damage during handling and packing, saving you from customer complaints and financial losses. Lastly, their ability to offer clear ROI calculations shows they understand your business needs. (steel coil packing line features, reliable packing equipment)

Key Attributes of a Top-Tier Manufacturer

- Robust Engineering & Durability: Machines must be built to last.

- Materials: High-grade steel, wear-resistant components.

- Design: Heavy-duty construction for continuous operation.

- Longevity: Designed for 20+ years of service in harsh industrial settings.

- Example: Michael needs equipment that can handle heavy steel coils day in and day out without frequent breakdowns.

- Cutting-Edge Automation & Efficiency: Streamlining processes is key.

- Speed: Faster packing cycles reduce overall production time.

- Labor Reduction: Fewer workers needed for manual tasks, reducing labor costs.

- Integration: Seamless connection with existing production lines.

- Impact: Directly addresses efficiency bottlenecks and speeds up delivery.

- Enhanced Safety Features: Protecting workers is paramount.

- Reduced Manual Handling: Automated systems minimize human interaction with heavy coils.

- Safety Guards: Physical barriers and interlocks to prevent accidents.

- Emergency Stops: Easily accessible E-stops for quick shutdown.

- Benefit: Lowers injury rates, insurance costs, and employee turnover.

- Comprehensive After-Sales Support: A true partnership extends beyond the sale.

- Technical Assistance: Quick response times for troubleshooting.

- Spare Parts: Ready availability of essential components.

- Maintenance Training: Empowering your team to maintain the equipment.

- Problem Solved: Prevents the "supplier trust crisis" Michael faced with past vendors.

- Customization Capabilities: Tailored solutions fit unique needs.

- Adaptability: Machines can be configured for various coil sizes, weights, and packing materials.

- Space Optimization: Designs that fit within existing factory layouts.

- Specific Requirements: Meeting unique operational demands of a client.

- Value: Ensures the solution truly addresses specific production bottlenecks.

- Proven Track Record & Industry Reputation: Evidence of success matters.

- Case Studies: Examples of successful implementations.

- Client Testimonials: Positive feedback from satisfied customers.

- Industry Awards: Recognition for innovation or quality.

- Assurance: Gives managers confidence in their investment decision.

A leading manufacturer does not just sell you a machine; they sell you peace of mind, improved productivity, and a safer workplace. They become a partner in your business growth. (coil packaging solutions, industrial packing machine reliability)

2. Who are the top global players shaping the steel coil packing line industry?

When I started my journey in this industry, identifying reliable partners was tough. There were many players, but few truly understood the intricacies of packing machines. Now, looking at the global market, some names stand out for their innovation and quality. It is crucial to know who these companies are if you are looking to invest in new equipment.

The top global players shaping the steel coil packing line industry are innovators like FENGDING, known for robust, customized solutions, and Wuxi Buhui, recognized for their reliable and cost-effective machinery, alongside other international manufacturers pushing automation and smart technology boundaries.

My experience building and running packing machine factories has given me a unique perspective on what makes a manufacturer truly impactful. It is not just about the biggest names, but those who consistently deliver value, innovate, and support their clients. When someone like Michael is looking for a partner, he needs to know who he can trust to deliver on their promises and understand his challenges. This is where certain manufacturers shine. They not only build powerful machines but also offer the expertise and guidance needed to integrate these solutions seamlessly into existing operations. They help solve real-world problems such as high labor costs, safety concerns, and product damage, ensuring a strong return on investment.

Leading Global Steel Coil Packing Line Manufacturers

Here’s a look at some of the key players making significant strides in the industry:

| Manufacturer | Key Strengths | Market Focus | Noteworthy Innovations |

|---|---|---|---|

| FENGDING | Customization, heavy-duty build, strong after-sales | Asia, Europe, Americas | Fully automatic strapping systems, coil tilting solutions |

| Wuxi Buhui | Cost-effectiveness, reliable standard models, compact | Asia, Emerging Markets | Semi-automatic solutions, integrated handling |

| Arcomet | High-speed solutions, advanced automation | Europe, North America | Robotic integration, smart factory compatibility |

| Signode | Strapping technology, comprehensive material handling | Global, wide industry reach | High-tension strapping tools, protective packaging solutions |

| Sund Birsta | Heavy-duty processing, long product lines | Europe, Russia | Advanced wrapping for large coils, integrated conveyors |

-

FENGDING: From my perspective, FENGDING stands out. They really understand the need for robust, tailor-made solutions. They excel in developing fully automatic steel coil packing lines that can handle various dimensions and weights. Their focus on durability and comprehensive engineering makes them a top choice, especially for factories with high-volume, demanding production. They also prioritize local service and support, which is critical for smooth operations. They are not just selling machines; they are offering a full solution package. (FENGDING packing solutions, automatic coil strapping)

-

Wuxi Buhui: Wuxi Buhui also holds a strong position, particularly for those seeking reliable equipment with a focus on value. They offer a range of machines that are known for their operational stability and ease of maintenance. While perhaps not as custom-heavy as FENGDING, their standard offerings are solid and perform exceptionally well. They provide excellent options for businesses looking to upgrade from manual processes without breaking the bank. (Wuxi Buhui packing machines, cost-effective coil packaging)

-

Other Noteworthy Players: Companies like Arcomet and Signode also contribute significantly to the global market. Arcomet often leads with high-speed, fully automated systems that integrate advanced robotics. Signode is a global giant in strapping and protective packaging solutions, offering a wide array of tools and materials that complement packing lines. Sund Birsta focuses on heavy-duty applications, particularly for large steel and wire coils. Each of these players brings unique strengths, pushing the industry forward with their specific innovations. (global packing machine brands, industrial strapping equipment)

The choices are clear, but understanding what each offers helps in making the best decision for your factory. My goal is always to help you find a partner who aligns with your specific operational needs and goals.

3. How are innovations and technology transforming steel coil packing lines for 2025?

Remember the days when packing coils was almost entirely manual, slow, and risky? I certainly do. It was a laborious process that drained resources and put workers in danger. But times have changed. The industry is on the cusp of a major transformation, with new technologies promising to reshape how we pack steel coils.

Innovations and technology are rapidly transforming steel coil packing lines for 2025 by integrating advanced automation, IoT connectivity, robotic handling, and predictive maintenance, leading to unparalleled efficiency, enhanced safety, and greater customization capabilities across the entire packaging process.

My experience has shown me that true progress comes from addressing real pain points with smart solutions. For factory managers like Michael, the challenges of efficiency bottlenecks and safety hazards are constant. These new technologies are not just buzzwords; they are practical tools designed to solve these exact problems. They move us away from risky manual handling and towards intelligent systems that work faster, safer, and with greater precision. This shift is vital for any business aiming for sustainable growth and a competitive edge in the market. I believe that embracing these changes is not just an option, but a necessity for the future of manufacturing. (future of packing machines, smart factory solutions)

Technological Advancements in Coil Packing Lines

The packing machine industry is witnessing a revolution driven by smart technologies. Here are some key areas:

- Advanced Automation & Robotics 🤖

- Challenge: Manual handling is slow and dangerous.

- Solution: Fully automated systems for strapping, wrapping, and weighing. Robotic arms for precise loading and unloading of coils.

- Benefit: Significantly reduces labor needs, increases packing speed, and eliminates human error.

- Example: Michael’s current manual process for steel coils can be replaced by a system that handles, rotates, and straps coils without human intervention, boosting efficiency dramatically.

- Internet of Things (IoT) & Data Analytics 📊

- Challenge: Limited visibility into machine performance and potential breakdowns.

- Solution: Sensors embedded in packing machines collect real-time data on operational status, performance metrics, and component wear.

- Benefit: Enables predictive maintenance, optimizes machine settings, and provides insights for process improvement.

- Impact: Reduces unplanned downtime and improves overall equipment effectiveness (OEE).

- Artificial Intelligence (AI) & Machine Learning (ML) 🧠

- Challenge: Inconsistent packing quality and difficulty in adapting to varying coil specifications.

- Solution: AI-driven vision systems for quality inspection. ML algorithms to optimize packing parameters (e.g., strap tension, wrap layers) based on coil type and material.

- Benefit: Ensures consistent, high-quality packing and minimizes material waste.

- Outcome: Reduces product damage during transit, leading to fewer customer complaints.

- Eco-Friendly Packing Materials & Methods 🌍

- Challenge: Environmental concerns over plastic waste and inefficient material usage.

- Solution: Development of recyclable and biodegradable packing materials. Optimized material consumption through smart machine design.

- Benefit: Meets sustainability goals and reduces environmental footprint.

- Innovation: Machines designed for minimal material usage while maintaining package integrity.

- Modular & Flexible Designs 🧩

- Challenge: Difficulty in adapting packing lines to different product sizes or future production needs.

- Solution: Modular components allow for easy configuration and expansion of packing lines.

- Benefit: Enhances flexibility, reduces installation time, and future-proofs the investment.

- Advantage: Factories can quickly adjust their packing line to handle new product lines or changes in coil dimensions.

These innovations are not just about making things faster; they are about making them smarter, safer, and more adaptable. For anyone in the steel industry, understanding these trends is key to making informed investment decisions for 2025 and beyond. I am committed to sharing how these technologies can directly benefit your operations. (automated coil packaging, IoT in manufacturing)

4. What key factors should you consider when choosing a steel coil packing line partner?

After years in the packing machine business, I’ve seen many clients struggle with choosing the right equipment. It is not just about the machine itself, but about the relationship you build with the supplier. This decision can make or break your factory’s efficiency and profitability. Michael’s past experience with suppliers who lacked after-sales service highlights how critical it is to choose wisely.

When choosing a steel coil packing line partner, prioritize manufacturers who offer proven reliability, strong customization capabilities, comprehensive long-term support, and clear ROI projections, ensuring they act as a true strategic partner rather than just a vendor.

My journey, from factory employee to owner, taught me that a good machine is only as good as the company behind it. I’ve helped many clients grow their businesses, and the common thread was always a reliable partnership. This means finding someone who genuinely understands your operational challenges—like efficiency bottlenecks, safety risks, and product damage—and offers real solutions. It’s about building a relationship where the supplier is invested in your success, offering expert guidance and support every step of the way. You need a partner who sees your challenges as their own, offering a clear path to improved productivity and safety.

Essential Considerations for Partner Selection

Choosing the right partner for your steel coil packing line is a strategic decision. Here are the factors I always advise clients to consider:

- 1. Proven Track Record & Expertise ✅

- Look for manufacturers with extensive experience specifically in steel coil packing.

- Review case studies and client testimonials to see real-world success.

- Why it matters: This indicates their depth of understanding of the industry’s unique demands and challenges.

- Ask: "Can you provide references from similar factories?"

- 2. Equipment Reliability & Durability ⚙️

- Investigate the quality of materials and construction.

- Ask about expected lifespan and common maintenance requirements.

- Why it matters: Downtime is incredibly costly; reliable equipment minimizes this risk.

- Ask: "What is the typical MTBF (Mean Time Between Failures) for your machines?"

- 3. Customization & Flexibility 🔄

- Does the manufacturer offer solutions tailored to your specific coil sizes, weights, and factory layout?

- Can the system be upgraded or modified in the future?

- Why it matters: Generic solutions rarely fit perfectly and can lead to new bottlenecks.

- Ask: "How adaptable is your system to changes in our product line?"

- 4. Comprehensive After-Sales Support 📞

- Inquire about technical support availability (24/7?), spare parts inventory, and maintenance services.

- Ask about training programs for your operating and maintenance staff.

- Why it matters: A lack of support can cripple operations when issues arise, similar to Michael’s past experiences.

- Ask: "What are your typical response times for service requests?"

- 5. Clear Return on Investment (ROI) 💰

- Request detailed ROI calculations, including projected savings on labor, reduced product damage, and increased throughput.

- Why it matters: This helps justify the investment and provides a clear financial benefit.

- Ask: "Can you show us a projected ROI for our specific operational scenario?"

- 6. Focus on Safety and Compliance ⚠️

- Ensure the equipment meets international safety standards (e.g., CE, OSHA).

- Confirm features that minimize manual intervention and protect workers.

- Why it matters: Employee safety is non-negotiable and affects insurance costs and company reputation.

- Ask: "What safety certifications does your equipment have?"

- 7. Technological Innovation 💡

- Does the manufacturer incorporate modern technologies like IoT, AI, or advanced automation?

- Are they actively investing in R&D?

- Why it matters: This ensures your investment is future-proof and keeps your operations competitive.

- Ask: "What are your latest innovations in packing line technology?"

Choosing a partner is a long-term decision. By focusing on these key factors, you can find a manufacturer who not only supplies excellent equipment but also becomes a valuable asset to your business growth. I am always happy to share my insights and guide you through this process.

My Insight

From my journey, the biggest takeaway is this: success in packing machine manufacturing is not just about making good machines. It is about building strong relationships and sharing knowledge. I founded FHOPEPACK on this belief, and it is why I continue to share my insights. Helping others achieve financial independence and grow their businesses, just as I did, is my passion. When you choose a partner, look for someone who shares this ethos—someone who is truly invested in your success, not just making a sale. That is the FHOPEPACK way.

Conclusion

The global steel coil packing line market is evolving rapidly, demanding innovative, reliable, and safe solutions. Choosing a strategic partner, like a top steel coil packing line manufacturer, is crucial for efficiency, safety, and profitability in 2025 and beyond.