Future Trends in Steel Coil Strapping and Packing Lines | Automation, AI, and Sustainability

As a factory manager like Michael in Mexico, you probably feel the constant pressure. You are battling slow, manual packing processes, facing high risks of worker injury, and seeing valuable products damaged during internal transfers. These aren’t just operational headaches; they are direct hits to your bottom line and your team’s morale. The truth is, relying on outdated methods for steel coil and wire packing means you are losing money, risking safety, and struggling to keep up.

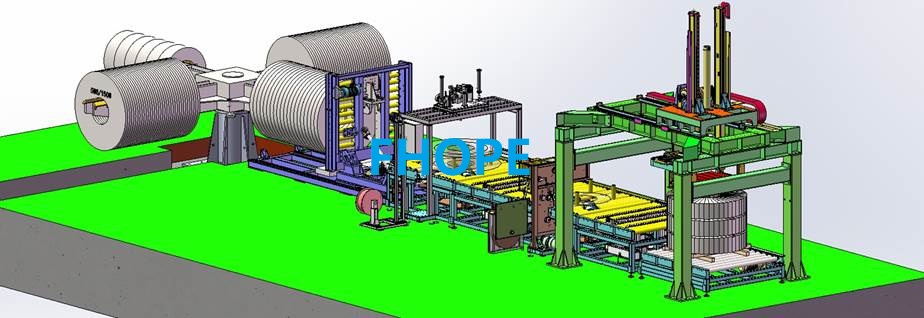

The future of steel coil strapping and packing lines is rapidly advancing towards intelligent, automated, and environmentally conscious solutions. This shift involves a significant move to advanced automation for greater speed and precision, the integration of AI for predictive maintenance and operational optimization, and a strong focus on sustainable practices like eco-friendly materials and energy efficiency. These innovations are set to boost operational efficiency, enhance worker safety, and reduce the environmental footprint of heavy industry. (future steel coil packing trends, automated strapping solutions)

The challenges you face today with efficiency, safety, and product loss are not unique. Many operations are looking for better ways. Understanding these trends is not just about staying current. It is about making smart choices for your factory’s future. Let us explore how these advancements can directly benefit your business, solve your current pain points, and drive long-term success.

1. How is Automation Reshaping Steel Coil Packing Lines for Efficiency and Safety?

Are you still relying on a large workforce for heavy-duty coil packing and handling? This approach is slow, costly, and dangerous. The risk of injury, slow production speeds, and inconsistent package quality are major problems. It stops your factory from reaching its full potential.

Automation is fundamentally changing steel coil packing by replacing manual processes with high-speed, precision machinery for strapping, wrapping, and handling. This shift dramatically improves operational efficiency, reduces labor costs, minimizes human error, and, most importantly, eliminates the high safety risks associated with manually handling heavy steel coils and wires. Automated systems ensure consistent, secure packaging, leading to fewer product damages and higher customer satisfaction. (automated steel coil packing, industrial safety solutions)

Key Automated Technologies Transforming Packing

In my journey, from working in a packing machine factory to building my own, I have seen first-hand the incredible difference automation makes. We are moving away from manual labor. We are embracing machines that do the heavy lifting, the precise strapping, and the secure wrapping. For example, manual coil handling is slow and dangerous. Workers struggle with heavy steel coils, leading to high injury rates and slow processing. Automated coil handling systems, like coil tilters and transfer carts, can move these massive loads safely and quickly. This reduces the risk of injury to almost zero. It also speeds up the entire packaging process.

Here are some core automation technologies:

- Automatic Strapping Machines: These machines apply steel or PET straps quickly and consistently around coils. They replace manual strapping, which is slow and often inconsistent. This improves package integrity and reduces material waste. ⚙️

- Horizontal and Orbital Wrappers: These systems tightly wrap coils with protective film or paper. They ensure comprehensive coverage, protecting against rust, dust, and damage during transport. Manual wrapping is time-consuming and often leaves gaps. 🛡️

- Robotic Handling Systems: Robots can pick, place, and stack coils. They work with high precision and speed. This frees up human workers from repetitive and dangerous tasks. They also reduce product damage during internal transfers. 🤖

- Integrated Packing Lines: These are complete systems that link multiple machines. They can handle an entire coil packing process from start to finish. This includes entry, weighing, strapping, wrapping, and exiting the line. Such integration reduces bottlenecks and increases overall factory throughput. 📈

Impact on Workforce and Safety

The most direct and welcome impact of automation is on worker safety. For factory managers like Michael, reducing accidents is a top priority. Manual handling of heavy coils or steel wire bundles carries immense risk. Automated systems remove human workers from these dangerous zones. This significantly lowers the chance of strains, crushes, and other severe injuries. Less injuries mean lower insurance costs and a more stable workforce. Beyond safety, automation makes the workforce more productive. Workers can focus on tasks that require critical thinking or oversight, rather than repetitive physical labor. This transformation creates a safer, more efficient work environment for everyone. It helps companies like Michael’s grow without sacrificing employee well-being. (automatic coil strapping machines, safer packing operations, reduced labor costs)

2. What Role Will AI and Data Analytics Play in Optimizing Coil Strapping Operations?

Have you ever faced unexpected machine breakdowns that halted your entire production? Do you struggle to find ways to squeeze more efficiency out of your current packing line? Relying on guesswork or scheduled maintenance often leads to costly downtime and missed opportunities. This traditional approach limits your factory’s potential.

Artificial Intelligence (AI) and data analytics are set to revolutionize coil strapping operations by enabling predictive maintenance, optimizing machine performance through real-time adjustments, and enhancing quality control. AI systems analyze vast amounts of operational data to forecast potential equipment failures, fine-tune packing parameters for optimal material usage, and identify efficiency bottlenecks, leading to significant cost savings and reduced downtime. This proactive approach ensures maximum uptime and consistent output. (AI in industrial packing, data analytics for manufacturing efficiency)

Predictive Maintenance Power

In the past, factories either waited for a machine to break down or performed maintenance on a fixed schedule. Both methods are inefficient. Waiting for a breakdown causes sudden production halts and rush repairs. Fixed schedules often mean servicing machines that do not need it, wasting time and resources. AI changes this. By collecting data from sensors on packing machines – things like vibration levels, motor temperatures, and power consumption – AI algorithms can learn the normal operating patterns. They can detect subtle changes that indicate an upcoming problem.

Imagine a scenario where your coil strapping machine shows slight increases in motor temperature or abnormal vibration. An AI system can analyze this data in real-time. It can then alert maintenance teams to a potential bearing failure days or weeks before it actually happens. This allows for scheduled maintenance during non-production hours. This minimizes downtime and avoids costly, emergency repairs. This predictive capability transforms maintenance from a reactive cost to a strategic advantage. It ensures continuous operation and extends the lifespan of expensive equipment. (smart packing machine, operational data insights, reduced machine downtime)

Optimizing Operational Efficiency with Data

AI and data analytics do more than just predict failures. They actively optimize the packing process. Modern packing lines generate massive amounts of data. This data includes strapping tension, wrapping speed, material usage, and cycle times. AI algorithms can process this data to find patterns and suggest improvements.

Here is how data analytics helps:

- Parameter Adjustment: AI can recommend optimal settings for strap tension or wrapping patterns. This ensures secure packaging while using the least amount of material. This reduces waste and costs.

- Bottleneck Identification: By analyzing the flow of coils through the entire packing line, AI can pinpoint specific areas where delays occur. This allows managers to address these bottlenecks directly.

- Quality Control: AI-powered vision systems can detect flaws in packaging or product damage much faster and more accurately than human eyes. This ensures only high-quality products leave the factory.

- Energy Management: AI can monitor energy consumption across the packing line. It can suggest ways to reduce power usage, for example, by optimizing machine start-up sequences or identifying inefficient components.

By harnessing the power of AI, factories can move from simply producing to intelligently optimizing. This means lower operational costs, consistent product quality, and a significant competitive edge in the market. (AI-driven optimization, smart factory solutions, predictive analytics)

3. Why is Sustainability Becoming a Critical Factor in Modern Coil Packing Solutions?

Are you concerned about your factory’s environmental footprint? Do you face rising costs for packing materials and increasing pressure to comply with environmental regulations? Ignoring sustainability can lead to higher operational costs, negative public image, and regulatory fines. This shortsighted approach can hurt your business in the long run.

Sustainability is increasingly vital in modern coil packing, driven by stricter environmental regulations, consumer demand for eco-friendly practices, and the economic benefits of reduced material consumption and waste. Packing solutions are evolving to incorporate recyclable materials, optimize energy use in machinery, and minimize packaging waste, contributing to a greener supply chain and improved corporate responsibility. This focus not only benefits the planet but also offers long-term cost savings and enhances brand reputation. (eco-friendly packing solutions, sustainable industrial packaging)

Greener Materials and Energy

The push for sustainability starts with the materials we use and the energy we consume. For steel coil packing, this means rethinking traditional packaging choices. Many factories are now moving towards materials that are either recyclable, reusable, or made from recycled content.

Consider these sustainable material options:

- Recycled PET Straps: These straps offer similar strength to steel straps but are made from recycled plastics. They reduce reliance on virgin resources and are often recyclable themselves. ♻️

- Biodegradable or Compostable Films: While still developing for heavy-duty applications, these films aim to reduce plastic waste that ends up in landfills.

- Optimized Paper-based Wraps: Innovations in paper and cardboard materials offer robust protection with a lower environmental impact compared to some plastics.

Beyond materials, energy efficiency in packing machinery is crucial. Modern machines are designed to consume less power during operation and even in standby mode. Features like energy-efficient motors, intelligent power management systems, and regenerative braking can significantly reduce the overall energy footprint of a packing line. This not only benefits the environment but also reduces operational costs. It is a win-win for factories aiming for greener operations and lower utility bills. (reduced waste packing, energy efficient machinery, recycled packing materials)

Long-Term Business Advantages

Embracing sustainability in your packing operations is not just about being environmentally friendly; it is a smart business strategy. Michael, as a factory manager, understands the importance of cost control and market competitiveness. Sustainable practices offer clear financial and reputational benefits:

- Cost Savings:

- Reduced Material Consumption: Optimized packing patterns and precise application by automated machines minimize waste.

- Lower Energy Bills: Energy-efficient equipment directly translates to reduced electricity costs.

- Waste Management Costs: Less waste means lower disposal fees.

- Regulatory Compliance: Governments worldwide are implementing stricter environmental regulations. Adopting sustainable practices proactively helps factories comply with these rules. This avoids potential fines and legal issues.

- Enhanced Brand Reputation: Consumers and business partners increasingly prefer working with companies that demonstrate environmental responsibility. A commitment to sustainability can be a powerful marketing tool. It attracts new clients and strengthens existing relationships.

- Attracting Talent: Employees, especially younger generations, are often drawn to companies with strong sustainability initiatives. This helps in recruiting and retaining skilled workers.

By investing in sustainable packing solutions, factories position themselves for long-term resilience and success. It is an investment in the planet and in the profitability and reputation of the business. (sustainable industrial practices, green manufacturing benefits, environmental compliance)

4. How Can Manufacturers Choose the Right Future-Proof Packing Line for Long-Term ROI?

Making a large investment in new packing machinery is a big decision. You want to be sure it will pay off in the long run. If you focus only on the initial purchase price, you risk ending up with a system that quickly becomes outdated, unreliable, or unable to adapt to your changing needs. This can lead to costly upgrades and missed opportunities.

To select a future-proof packing line, manufacturers must prioritize adaptability to new technologies, scalability to meet changing production demands, and robust after-sales support from a knowledgeable partner. Focusing on total cost of ownership (TCO) over initial price, evaluating a supplier’s track record, and ensuring the system integrates with existing factory operations are key to maximizing long-term Return on Investment (ROI) and avoiding costly upgrades and operational disruptions. (future-proof packing investment, choosing industrial packing supplier)

Beyond the Purchase Price

When considering a new packing line, the upfront cost is only one piece of the puzzle. As Randal, I have seen many companies regret making decisions based solely on the lowest bid. The real value comes from understanding the Total Cost of Ownership (TCO). This includes the purchase price, yes, but also installation, training, energy consumption, maintenance, spare parts, and the potential cost of downtime over the machine’s lifespan. A cheaper machine might have higher energy usage, require more frequent maintenance, or break down more often. This would quickly erode any initial savings.

Here are factors to consider for TCO:

- Energy Efficiency: How much power does the machine consume during operation and standby?

- Maintenance Requirements: What is the recommended maintenance schedule, and how much do parts cost?

- Spare Parts Availability: Are spare parts readily available, or will there be long lead times for critical components?

- Operator Training: Is comprehensive training provided for your staff?

- Expected Lifespan: How long is the machine expected to perform reliably?

Choosing a packing line with a strong track record of reliability and efficiency, even if it costs a bit more initially, nearly always offers a better long-term ROI. It is about investing in consistent performance, not just a machine. (total cost of ownership, long-term packing solutions, reliable packing equipment)

The FHOPEPACK Advantage

When Michael seeks a true partner, not just a vendor, he is looking for someone with deep industry knowledge and a commitment to long-term support. This is where my experience, as someone who started on the factory floor and built a successful packing machine factory, becomes valuable. I understand the challenges you face every day.

At FHOPEPACK, we believe in providing not just machines but comprehensive solutions. Here is what a knowledgeable partner offers:

- Customization: Every factory has unique needs. We work with you to design a packing line that fits your specific coil dimensions, production volume, and factory layout. This ensures maximum efficiency and seamless integration.

- Scalability: Your factory will grow. A good packing line should be able to grow with you. We offer modular designs that allow for future upgrades or additions, so your investment remains relevant.

- After-Sales Service and Support: What happens when a machine needs service? Reliable technical support, readily available spare parts, and expert assistance are crucial. This minimizes downtime and keeps your operations running smoothly. We pride ourselves on building lasting relationships with our clients, providing the guidance needed to succeed.

- Industry Insights: We share our expertise on the latest technologies and best practices. This ensures you are always ahead of the curve, making informed decisions for your business.

By choosing a partner like FHOPEPACK, you are not just buying a machine. You are gaining an expert ally who understands your business. We help you navigate the complexities of automation, AI, and sustainability. We ensure your investment in a new packing line delivers exceptional long-term ROI and supports your factory’s growth. (packing line customization, reliable packing equipment support, expert packing machine guidance)

Conclusion

The future of steel coil packing line is dynamic. Embracing automation, AI, and sustainability ensures efficiency and growth. We are here to guide your journey.