What Are the Future Trends in Steel Coil Packing Machines: AI, Automation, and Robotics?

For years, I have seen countless factory managers like Michael Chen struggle with outdated, labor-intensive packing processes. They face constant pressure to increase output, cut costs, and ensure worker safety, often battling slow lines, damaged products, and high injury risks. The traditional methods simply cannot keep up with today’s demands. (manual packing challenges, factory efficiency bottlenecks, operational pressures)

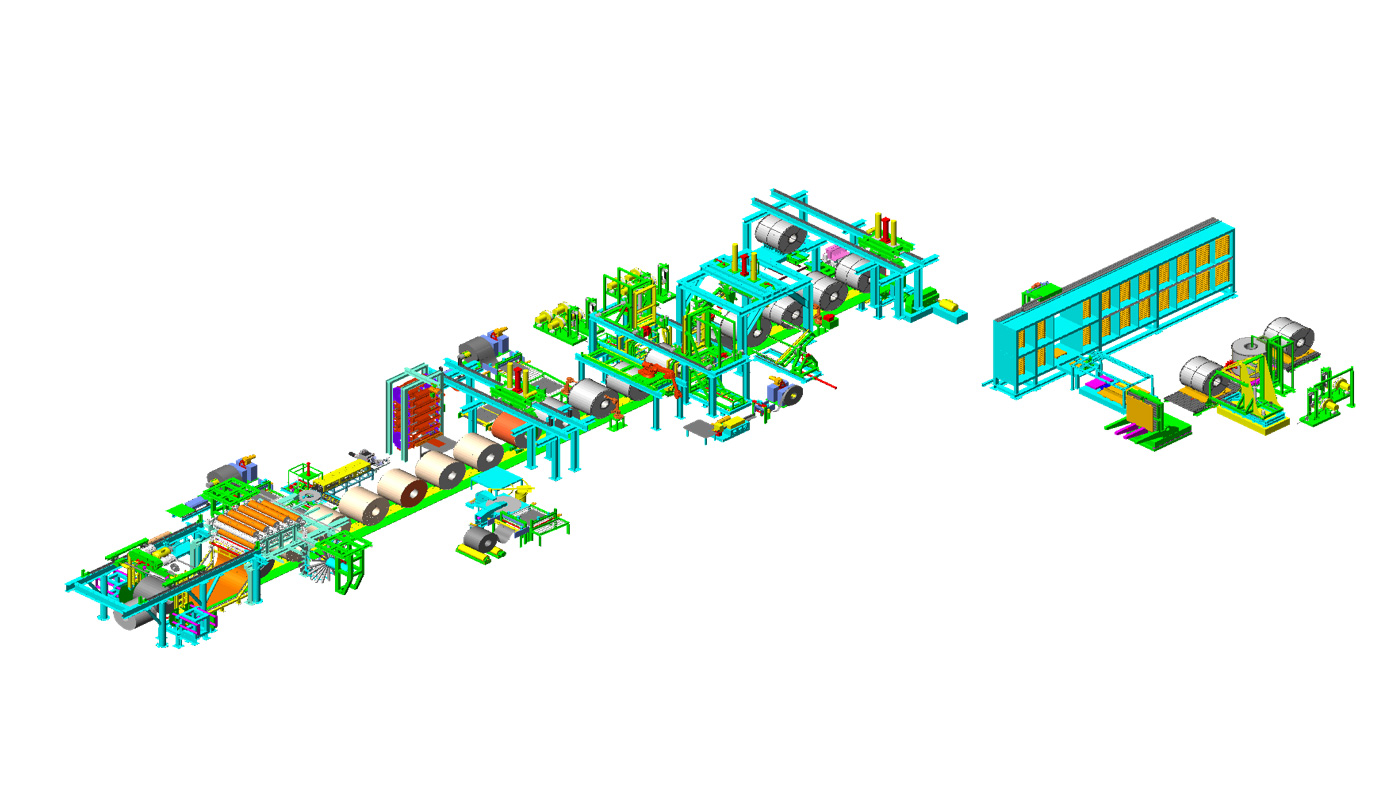

The future of steel coil packing is rapidly evolving, driven by the integration of Artificial Intelligence (AI), advanced automation, and sophisticated robotics, which together promise to revolutionize efficiency, enhance safety, and drastically reduce operational costs for heavy-duty manufacturing facilities worldwide. These technologies are moving beyond mere upgrades, offering complete transformations for packing lines, from input to final output. (future packing trends, smart packing solutions, industrial packaging innovation)

The challenges Michael faces daily are real, and I’ve experienced them myself during my journey building FHOPEPACK. That’s why I’m passionate about sharing how these emerging technologies are not just theoretical concepts but practical solutions ready to empower businesses and overcome these critical obstacles. Let’s dive deeper into how AI, automation, and robotics are paving the way for a smarter, safer, and more profitable future in steel coil packing. (packing machine expertise, operational improvement, manufacturing solutions)

1. How is Artificial Intelligence (AI) Reshaping Steel Coil Packing?

Many factory managers view AI as a complex, distant concept. But the reality is that AI is already providing tangible benefits, solving real-world packing challenges that have plagued factories for decades. Are you still making critical packing decisions based on guesswork or historical data alone? (AI in manufacturing, packing process optimization, data-driven decisions)

Artificial Intelligence (AI) is transforming steel coil packing by enabling predictive maintenance, optimizing material flow, and enhancing quality control through real-time data analysis, moving operations from reactive to proactive and significantly improving overall line efficiency and product integrity. This smart oversight helps anticipate problems before they occur, reducing downtime and waste across the entire packing process. (AI applications in packaging, predictive maintenance solutions, smart quality control)

AI brings an unprecedented level of intelligence to packing machines. When I started FHOPEPACK, even advanced machines were reactive. Today, AI allows machines to learn and adapt. For example, my clients, including those shipping steel coils and wire, often struggled with inconsistent wrapping quality or unexpected machine breakdowns. AI algorithms can analyze vast amounts of data from sensors embedded in the packing line. This data includes parameters like coil size, weight, material type, wrapping tension, and machine performance metrics. By crunching these numbers, AI can detect subtle patterns that human operators might miss. This leads to predictive maintenance, where the system alerts you to potential equipment failures long before they happen. Imagine knowing a specific part is about to wear out weeks in advance. You can schedule maintenance during planned downtime, avoiding costly, unscheduled stops. This proactive approach saves thousands in repair costs and prevents significant production delays. Furthermore, AI enhances quality control. It can use computer vision to inspect each coil for damage or imperfect wrapping in real time. If a defect is found, the system can flag it immediately, or even adjust machine settings to correct the issue. This reduces product loss and customer complaints, which Michael Chen knows can hurt profits. For example, if a steel coil’s edge is consistently getting damaged during a specific stage, AI can identify the exact cause and suggest adjustments to the conveyor speed or handling mechanism. This level of insight makes the packing process much more reliable and efficient. (AI for predictive maintenance, intelligent quality control, operational efficiency with AI, data analytics in packing)

- Key Benefits of AI in Packing:

- 📊 Predictive Analytics: AI forecasts potential machine failures, allowing for scheduled maintenance and minimizing unexpected downtime.

- ⚙️ Process Optimization: It continuously analyzes packing parameters (speed, tension, material flow) to ensure peak performance and minimize waste.

- 🔍 Enhanced Quality Control: AI-powered vision systems detect defects in real-time, preventing damaged products from reaching customers.

- 💡 Adaptive Learning: The system learns from new data, improving its recommendations and performance over time, making your packing line smarter.

2. Can Automation Significantly Improve Efficiency and Safety in Packing Lines?

For many years, factories relied heavily on manual labor for packing steel coils. This approach comes with inherent risks and limitations. If you are still moving heavy coils by hand or with outdated equipment, you know the struggle: slow speeds, high labor costs, and constant worry about worker injuries. Is there a better way to protect your team and boost your output? (manual labor challenges, worker safety concerns, inefficient packing methods)

Automation significantly improves efficiency and safety in steel coil packing lines by replacing hazardous manual tasks with precise, high-speed machinery, leading to faster throughput, reduced labor costs, and a drastic decrease in workplace accidents and product damage. From automatic strapping to intelligent conveying systems, automation ensures consistent quality and a safer environment for your entire operation. (automated packing solutions, industrial safety improvements, cost-effective manufacturing)

When I first started in the packing machine industry, automation was largely about simple mechanical systems. Today, it’s about intelligent, integrated processes that handle everything from coil reception to final dispatch. Michael Chen’s concern about efficiency bottlenecks and safety hazards from manual handling resonates deeply with my experience. Automation addresses these directly. For instance, automatic strapping machines can apply steel or plastic straps with consistent tension much faster and more reliably than manual labor. This reduces the risk of human error and ensures coils are securely bundled for transport, minimizing product damage during transit. Consider the sheer weight of steel coils; manually moving or turning them is incredibly dangerous, a major cause of serious injuries in factories. Automated coil handling systems, like specialized conveyors and coil cars, take humans out of harm’s way. These systems are designed to safely transport and orient coils, even those weighing several tons, with precision. This not only eliminates the risk of strains, crushes, and falls but also frees up your workforce to focus on more complex, value-added tasks. By automating these repetitive, heavy-lifting tasks, factories can see a direct reduction in insurance costs and employee turnover rates, creating a more stable and productive work environment. My own experience building FHOPEPACK taught me that investing in robust, automated equipment is not just about throughput, but about creating a sustainable and ethical workspace. This leads to a healthier bottom line and a happier workforce. (automated strapping machines, safe coil handling systems, labor cost reduction, workplace accident prevention, industrial automation benefits)

- Impact of Automation on Operations:

- 🔄 Increased Throughput: Machines operate continuously at higher speeds than human workers, dramatically speeding up the packing process.

- 🛡️ Enhanced Safety: Eliminates human interaction with heavy machinery and materials, drastically reducing the risk of injuries.

- 💰 Reduced Labor Costs: Fewer workers are needed for repetitive, heavy tasks, leading to significant savings over time.

- 📈 Consistent Quality: Automated systems perform tasks with uniform precision, ensuring consistent packing quality every time.

3. What Impact Do Robotics Have on Heavy-Duty Material Handling and Packaging?

The image of robots might still feel futuristic for some factory managers, yet these machines are increasingly becoming indispensable in heavy industrial settings. Are you still relying on traditional methods that limit flexibility and expose your workers to unnecessary risks when handling massive, unwieldy materials like steel coils? (robotics in heavy industry, material handling challenges, outdated handling methods)

Robotics are fundamentally changing heavy-duty material handling and packaging by providing unparalleled precision, strength, and flexibility, allowing for the safe and efficient movement, stacking, and palletizing of even the heaviest steel coils and wire products, far surpassing human capabilities in terms of speed and consistency. These robotic systems can operate in harsh environments, reducing human exposure to danger and significantly improving overall operational capacity. (industrial robotics, heavy material packaging, automated palletizing, robotic handling systems)

Robots are the muscle and precision of the modern packing line. Unlike fixed automation, which performs a specific, repetitive task, industrial robots offer incredible versatility. They can be programmed to perform a wide array of functions, from picking and placing heavy steel coils onto pallets to precise stacking patterns and even intricate wrapping procedures. This adaptability is crucial in an industry where product sizes and packing requirements can vary significantly. Michael Chen mentioned product loss due to damage during internal transfer. Robots, with their consistent movements and programmed precision, drastically reduce the likelihood of such incidents. They can handle delicate edges of steel coils or precise placement of wire bundles with a gentleness and accuracy that human operators cannot consistently match, especially over long shifts. Consider a large steel coil weighing several tons. A robotic arm, equipped with specialized grippers or vacuum lifters, can pick up, rotate, and place this coil exactly where it needs to be, hour after hour, without fatigue or error. This not only speeds up the process but also eliminates the most dangerous aspects of coil handling, making the workplace dramatically safer. When I was building my factory, I saw firsthand how much human energy was spent on heavy lifting. Robotics allows that energy to be redirected, enhancing productivity and creating a safer work environment for everyone. These systems are also designed to withstand harsh factory conditions, operating reliably in dusty, hot, or noisy environments where human presence would be challenging or dangerous. (robotic coil handling, industrial robot applications, precision material placement, workplace safety with robots, flexible packaging solutions)

- Why Robotics is a Game-Changer:

- 💪 Unmatched Strength & Endurance: Robots can handle extremely heavy loads continuously, without fatigue or injury risk.

- 🎯 High Precision & Repeatability: They perform tasks with exact movements every time, reducing errors and product damage.

- 🔄 Flexibility & Adaptability: Easily reprogrammable for different coil sizes, weights, and packing configurations.

- 🌡️ Harsh Environment Operation: Can work safely and reliably in conditions unsuitable or dangerous for human workers.

4. Why Should Factories Like Yours Invest in Smart Packing Technology?

After learning about AI, automation, and robotics, you might be asking: "Is this really worth the investment for my factory?" The initial cost might seem high, but what about the long-term benefits? Are you prepared to stay competitive and meet rising industry demands without these advancements? (smart technology investment, competitive manufacturing, future-proofing operations)

Factories should invest in smart packing technology because it delivers a compelling return on investment (ROI) through significant reductions in operational costs, dramatic improvements in worker safety, enhanced product quality, and the ability to scale production to meet increasing market demands, ultimately securing a more sustainable and profitable future. These integrated systems address critical pain points like efficiency bottlenecks, safety hazards, and product loss, as experienced by factory managers like Michael Chen. (ROI in automation, sustainable manufacturing, scalable production, future of industrial packing)

Investing in smart packing technology isn’t just about buying new machines; it’s about making a strategic decision to future-proof your business. From my journey starting FHOPEPACK and helping numerous clients grow, I’ve seen firsthand that the upfront investment quickly pays for itself through tangible savings and new opportunities. Consider Michael Chen’s challenges: high labor costs from manual processes, huge expenses from worker injuries, and profit loss from product damage. AI-driven automation and robotics directly address all these. By reducing reliance on manual labor, you cut down on wages, benefits, and the hidden costs associated with high turnover. More importantly, eliminating hazardous tasks protects your employees, leading to fewer insurance claims, lower medical expenses, and a more stable, motivated workforce. This creates a positive work environment, which is something I always strived for at FHOPEPACK. The precision of automated and robotic systems minimizes product damage, saving money on rework, scrap, and customer returns. Imagine Michael’s factory eliminating those costly complaints about damaged steel coil edges. Beyond cost savings, these technologies boost your capacity and consistency. You can process more coils faster and with uniform quality, meeting tighter deadlines and expanding your market reach. This enhanced efficiency means you can take on more orders and improve customer satisfaction, directly impacting your bottom line. Partnering with experts like me at FHOPEPACK, who understand these intricate systems and the specific challenges of coil packing, ensures you select the right solutions that truly drive business growth and offer a clear, measurable ROI. (packing line ROI, operational cost reduction, workforce safety, enhanced product quality, production scalability, expert partnership)

- Compelling Reasons to Invest:

- 💰 Strong ROI: Reduced labor, injury, and damage costs quickly offset the initial investment.

- ✅ Enhanced Competitiveness: Stay ahead by meeting demands for speed, quality, and reliability.

- 👷♀️ Improved Safety Record: Protect your most valuable asset—your employees—and reduce liabilities.

- 🌍 Sustainable Growth: Scalable and efficient operations support long-term business expansion and market leadership.

- 🤝 Strategic Partnership: Work with experienced providers to ensure the right solutions for your specific needs.

Conclusion

The future of steel coil packing is here, driven by AI, automation, and robotics, offering unparalleled efficiency, safety, and profitability. Investing in these advanced technologies with a reliable steel coil packing line is not just an upgrade; it’s a strategic move for sustainable growth.