Future-Ready Solutions in France | FHOPE’s Automatic Steel Coil Packing Line Powers Sustainable Steel Production?

Are you a factory manager, perhaps like Michael Chen, constantly battling production bottlenecks, rising operational costs, and the pressing need for safer work environments in your heavy industry plant? I know the pressure well. Every day brings new challenges to boost output, control expenses, and ensure every product leaves your facility in perfect condition. The steel industry, especially in dynamic markets like France, demands not just good, but exceptional, future-proof solutions. (Operational Challenges, Production Efficiency, Steel Industry France)

FHOPEPACK’s automatic steel coil packing lines are the answer, offering comprehensive, future-ready solutions that directly address the core challenges of modern steel production by significantly enhancing automation, safety, and efficiency across your entire operation, ensuring sustainable growth and competitive edge in demanding markets like France.

I have seen firsthand how the right technology can transform a factory. From my early days as an employee to building my own successful packing machine factory, I understand the critical decisions you face. This isn’t just about buying a machine; it’s about investing in a partnership that understands your pain points and delivers tangible results. Let’s explore how FHOPEPACK is leading this transformation.

1. How Can Automatic Packing Lines Solve Efficiency Bottlenecks in Steel Production?

Imagine your steel coils moving seamlessly from the production line to the packing station, without manual delays or bottlenecks. For many years, manual handling has been the biggest choke point in steel factories, slowing down delivery and eating into profits. This inefficiency creates a domino effect, impacting everything from lead times to customer satisfaction. (Manual Packing Issues, Production Delays, Steel Coil Throughput)

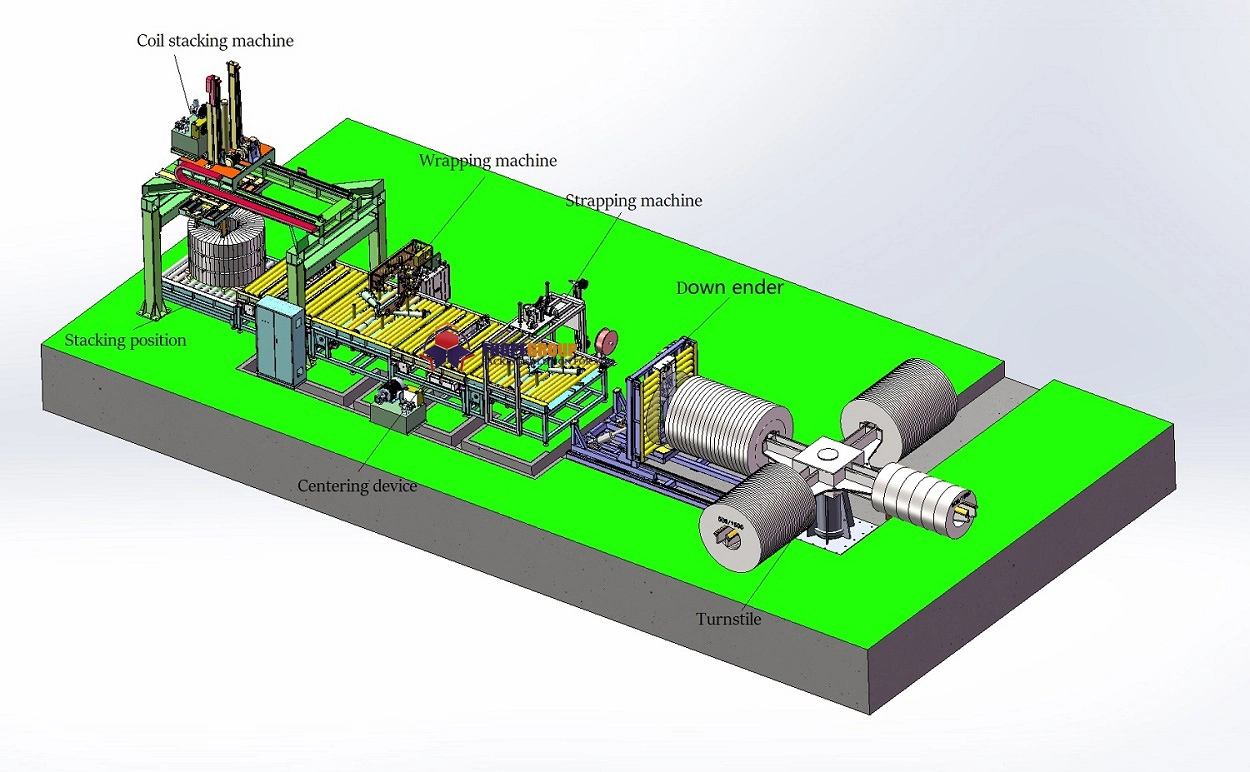

FHOPEPACK’s automatic steel coil packing lines eliminate these bottlenecks by automating the entire end-of-line process, from wrapping and strapping to conveying, drastically increasing throughput, reducing cycle times, and ensuring a continuous, high-speed flow of finished goods, vital for competitive markets in France and globally.

Solving efficiency bottlenecks is often the first step towards a truly modern and competitive factory. In France, as in many industrialized nations, the demand for higher output and faster delivery is constant. Our automatic packing lines are designed with this in mind. They integrate advanced robotics and intelligent control systems to manage the entire packing sequence. For instance, think about the time saved when a machine automatically detects coil dimensions, applies the correct amount of wrapping material, and securely straps the coil, all in a fraction of the time a human crew would take. This means more coils are ready for shipment each hour.

- Manual Process: Requires multiple operators, significant physical effort, prone to inconsistencies, and highly susceptible to fatigue-related slowdowns. Each coil might take 5-10 minutes for wrapping and strapping, depending on size and complexity.

- Automated Process: Needs minimal supervision, performs tasks with precision and repeatability, operates continuously without fatigue, and can complete the same tasks in 1-2 minutes per coil.

This speed increase isn’t just theoretical. I’ve witnessed factories struggling with dozens of workers dedicated solely to packing, yet still falling behind. By introducing an automated system, these factories can reallocate their valuable human resources to more complex tasks, like quality control or machine maintenance, rather than repetitive, heavy lifting. This shift not only accelerates production but also elevates the overall skill level within the workforce. Automation means fewer pauses, fewer errors, and a steady, predictable output, which is crucial for meeting tight deadlines and fulfilling large orders efficiently. The result is a significant boost in overall operational efficiency and a stronger competitive position, especially for facilities aiming to meet high European production standards. (Automated Production Flow, Cycle Time Reduction, Labor Optimization, European Manufacturing Standards)

2. What Role Do Automated Systems Play in Enhancing Worker Safety in Heavy Industries?

The heavy industry is inherently risky. Manual handling of bulky steel coils and wire rods puts workers at constant risk of severe injuries. Factory managers like Michael Chen bear the heavy responsibility of ensuring a safe workplace, but traditional methods often make this a daunting, if not impossible, task. Worker safety isn’t just a compliance issue; it’s a moral imperative and a critical factor in employee retention and insurance costs. (Workplace Hazard, Manual Handling Risk, Industrial Safety Regulations)

Automated packing systems are pivotal in transforming safety standards within heavy industries by eliminating the need for human intervention in hazardous tasks like lifting, moving, and securing heavy materials, thereby drastically reducing the incidence of musculoskeletal injuries, crushed limbs, and other severe accidents, ensuring a much safer environment for factory workers in facilities throughout France.

Dive deeper Paragraph:

Improving worker safety is one of the most compelling reasons to adopt automated packing solutions. In my journey through the packing machine industry, I have seen too many preventable accidents caused by manual handling of heavy items. Automatic systems remove workers from the direct vicinity of heavy, moving machinery and bulky products, fundamentally altering the risk profile of the packing area.

Consider these critical safety enhancements:

- Reduced Manual Lifting: Automated overhead cranes, conveyors, and robotic arms handle the heavy lifting of steel coils and wire rods. This eliminates strain injuries, back problems, and dropped loads, which are common in manual operations.

- Controlled Movements: Machines operate with precise, predictable movements, unlike human operators who can make errors due to fatigue or distraction. Safety sensors and interlocks further prevent unintended contact.

- Ergonomic Design: Workstations are designed to minimize repetitive motions and awkward postures, protecting workers from long-term occupational injuries.

- Compliance with Standards: Modern automated systems are built to meet rigorous international safety standards, providing factory managers like Michael with peace of mind regarding regulatory compliance. In France, adherence to EU safety directives is paramount, and our machines are engineered to exceed these expectations.

- Lower Insurance Premiums: A safer workplace directly translates to fewer compensation claims and lower insurance costs, offering a tangible financial benefit alongside the invaluable human benefit.

| Safety Aspect | Manual Packing | Automated Packing |

|---|---|---|

| Injury Risk | High (strains, crushed limbs) | Very Low (machine-human separation) |

| Fatigue Factor | Significant (leading to errors) | None (consistent operation) |

| Exposure to Hazards | Direct (moving loads, sharp edges) | Minimal (remote operation, safety zones) |

| Training Needs | Physical handling techniques | Monitoring, maintenance, safety protocols |

By integrating FHOPEPACK’s automated solutions, factories can foster a culture of safety that protects their most valuable asset – their people. This not only fulfills ethical obligations but also creates a more stable, productive, and attractive work environment. (Workplace Accident Prevention, Occupational Health, Regulatory Compliance France, Insurance Cost Reduction)

3. Can Modern Packing Technology Significantly Reduce Product Damage and Boost Profitability?

Product damage during internal transfer and packing is a silent drain on profitability. Nicks on steel coil edges, bent wire rods, or compromised packaging lead to customer complaints, returns, and ultimately, lost revenue. This issue often goes unnoticed until the cumulative cost becomes unbearable, affecting a factory’s reputation and bottom line. (Product Damage Costs, Customer Dissatisfaction, Profit Margin Erosion)

Modern automatic packing technology from FHOPEPACK is engineered to minimize product damage through precision handling, consistent wrapping, and secure bundling, ensuring that steel coils and wire rods arrive at their destination in pristine condition, thereby reducing waste, enhancing customer satisfaction, and directly boosting a factory’s overall profitability, a crucial factor for operations in France and beyond.

Protecting your product from damage is not just about aesthetics; it’s about preserving your profit margins and maintaining customer trust. In my experience, even minor damage can lead to significant financial repercussions, from reprocessing costs to damaged client relationships. FHOPEPACK’s automatic packing lines are designed with a keen focus on product integrity throughout the entire end-of-line process.

Here’s how our technology achieves this:

- Gentle and Precise Handling: Our systems utilize advanced gripping, lifting, and conveying mechanisms that minimize contact points and apply controlled force. This prevents dents, scratches, or deformation, especially crucial for sensitive coil edges or finished surfaces.

- Consistent Wrapping and Protection: Automated wrapping machines apply protective layers (like stretch film, VCI paper, or woven fabric) with consistent tension and overlap. This ensures uniform coverage, safeguarding against moisture, dust, and physical impact during storage and transit. This consistency is hard to achieve manually, where wrapping can be uneven or insufficient.

- Secure Bundling and Strapping: High-strength strapping machines apply uniform tension to secure coils and bundles, preventing shifting or unraveling during handling and transportation. This stability is key to avoiding impact damage.

- Automated Quality Checks: Integrated sensors can detect packaging anomalies, ensuring that every packaged product meets stringent quality standards before it leaves the factory.

Consider the Return on Investment (ROI) from reducing product damage:

- Reduced Scrap and Rework: Fewer damaged products mean less material waste and no need for costly re-processing.

- Fewer Customer Complaints: High-quality deliveries lead to satisfied customers and repeat business, strengthening your market position.

- Lower Logistics Costs: Fewer returns or warranty claims translate to reduced shipping and administrative expenses.

- Enhanced Brand Reputation: A reputation for delivering perfect products helps attract new clients and command premium pricing.

For a factory manager like Michael, understanding this ROI is vital. Investing in a machine that prevents even a small percentage of damage can quickly pay for itself. For example, if 2% of your steel coils are currently damaged during packing, and each coil is valued at $1000, reducing damage to 0.5% for an output of 1000 coils daily saves $15,000 per day. These are real numbers that speak directly to the bottom line, making the case for automation clear and compelling for any business striving for excellence, including those in competitive European markets. (Damage Prevention, Packaging Integrity, Cost Savings ROI, Customer Loyalty)

4. Why is Partnering with an Experienced Packing Machine Expert Crucial for Long-Term Success?

Many factory managers, including Michael, have faced the frustration of dealing with equipment suppliers who are only interested in making a sale. After-sales support is often lacking, leaving companies with complex machinery but no genuine guidance. This creates a deep trust crisis, making the decision to invest in new equipment a risky one. (Supplier Trust Issues, Post-Sale Support Gaps, Equipment Investment Risks)

Partnering with an experienced packing machine expert, like FHOPEPACK, is crucial because it ensures you receive not just state-of-the-art equipment but also invaluable industry insights, customized solutions, and robust, long-term support from a team led by professionals like me, Randal Liu, who understand the entire manufacturing lifecycle, providing the true partnership necessary for sustainable growth and overcoming operational challenges in France and globally.

Choosing a packing machine is more than a transaction; it’s a strategic decision that impacts your factory’s future for years to come. I built FHOPEPACK on the principle of partnership because I know what it’s like to be on both sides – as an employee and as a factory owner. I’ve personally navigated the complexities of the packing machine industry, from raw material handling (like coil packing) to delivering finished products (like steel wire packing). This journey gave me financial independence and helped many clients grow their businesses, and now I want to share that knowledge.

Here’s why a true expert partnership makes all the difference:

- Deep Industry Knowledge: An experienced partner possesses a profound understanding of industry-specific challenges, production flows, and regulatory requirements. We don’t just sell machines; we offer solutions tailored to your unique operational context, considering factors like material type, production volume, and factory layout.

- Customized Solutions: Your factory is unique, and a one-size-fits-all approach rarely works. A knowledgeable partner will conduct a thorough assessment of your current operations, identify specific pain points, and design a customized packing line that integrates seamlessly with your existing infrastructure. This might involve adapting machine configurations, control systems, or material handling processes.

- Reliable After-Sales Support: This is where many suppliers fall short. A true partner provides comprehensive training for your staff, readily available spare parts, and responsive technical support. This minimizes downtime and ensures your equipment operates at peak performance throughout its lifespan. For international operations, especially in France, quick and efficient support is non-negotiable.

- Long-Term Vision and Growth: An expert partner looks beyond the immediate sale. We aim to understand your long-term goals for automation, expansion, and sustainability. This allows us to recommend scalable solutions that can adapt as your business evolves, providing a future-proof investment rather than a temporary fix. My personal experience establishing and growing a factory means I can offer insights that purely sales-driven companies cannot.

When Michael looks for a supplier, he’s looking for someone who "gets it." He needs someone who understands production bottlenecks, safety hazards, and efficiency challenges. That’s exactly what FHOPEPACK offers: not just machines, but insights, solutions, and a commitment to your success, rooted in real-world factory experience. (Expert Consultation, Customized Machinery, Technical Support, Long-Term Business Partnership)

Conclusion

FHOPEPACK delivers future-ready, automated solutions that boost efficiency, enhance safety, reduce damage, and drive profitability, solidifying our role as a trusted partner in sustainable steel production through advanced steel coil packaging line.