FHOPE Machinery — Trusted Supplier for Steel Coil Packing Machines?

Are you constantly battling slow, manual packing processes that drag down your entire production line? Do safety risks from handling heavy steel coils keep you up at night, worrying about worker injuries and rising insurance costs? My name is Randal Liu, and I understand these challenges deeply. I have walked in your shoes, from a factory employee to building my own successful packing machine factory. I know the pressure to boost output, control costs, and keep your team safe. This is why I founded FHOPEPACK.

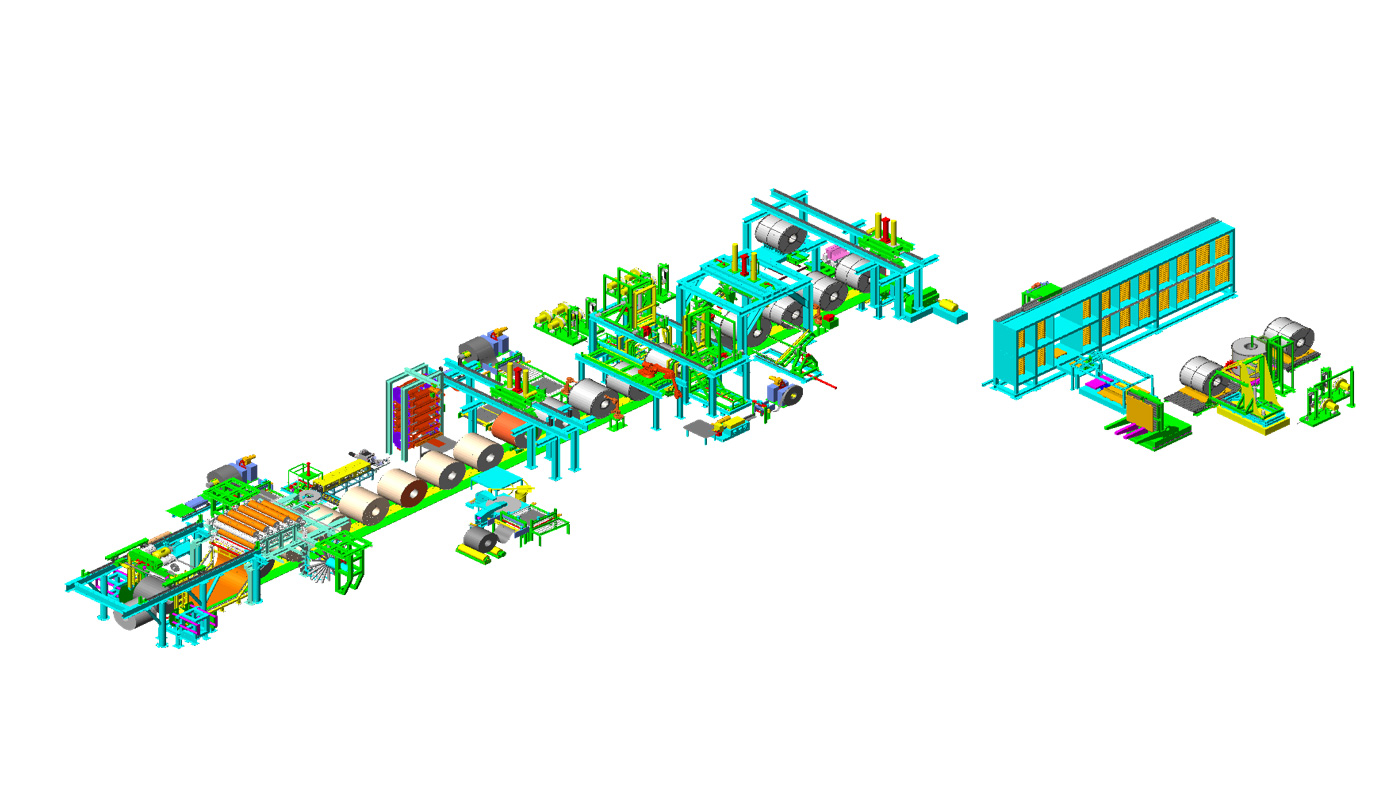

FHOPEPACK, with its MASTER PACKING MACHINE solutions, stands as a trusted supplier for steel coil packing machines because we offer more than just equipment; we provide reliable, efficient, and safe packaging automation, built on a foundation of real-world industry experience and a genuine commitment to client success.

Navigating the complexities of modern factory operations requires robust solutions and trusted partners. You need equipment that performs day in and day out, and a supplier who truly understands your operational bottlenecks and long-term goals. Let us explore how FHOPEPACK directly addresses the critical demands of today’s heavy manufacturing environment, offering real answers to your most pressing challenges.

1. How Can FHOPEPACK’s Steel Coil Packing Machines Boost Your Factory’s Efficiency?

Is your current steel coil and wire packing process a major bottleneck, slowing down deliveries and limiting your overall production capacity? The frustration of slow, labor-intensive end-of-line operations is a common pain point for factory managers like Michael Chen, who needs consistent, high-speed output.

FHOPEPACK’s steel coil packing machines dramatically boost factory efficiency by automating labor-intensive tasks, accelerating packing cycles, and ensuring consistent output, thus resolving production bottlenecks and enhancing overall throughput in heavy manufacturing operations.

Improving efficiency in a metal processing plant is not just about moving faster; it is about smarter processes that deliver consistent results. At FHOPEPACK, we design our steel coil packing lines to integrate seamlessly into your existing operations, transforming slow manual tasks into rapid, automated workflows. Consider the impact of automating the wrapping and strapping of heavy steel coils. What once took multiple workers and considerable time can now be completed in a fraction of the time with minimal human intervention. Our machines handle various coil sizes and weights with precision, ensuring each coil is wrapped securely and uniformly. This consistency not only speeds up the process but also reduces the chances of reworks, which are another silent drain on efficiency. For instance, our automatic strapping machines apply tension uniformly, securing the coil for transport without manual adjustments.

Imagine a scenario where your production line is no longer waiting for the packing stage. Our systems are built for high throughput, designed to keep pace with continuous production demands. This means more coils packed per hour, leading to increased daily and weekly output. For a factory manager like Michael, this directly translates to meeting production targets, reducing lead times, and improving delivery schedules. The automation also frees up valuable labor. Instead of assigning multiple workers to the repetitive and physically demanding task of packing, these employees can be redeployed to more skilled roles within the factory, optimizing your workforce allocation. We help factories move from a manual, bottleneck-prone process to a streamlined, automated system. This shift ensures every coil moves smoothly from the production floor to shipping, significantly enhancing overall operational flow.

Here is how our automation impacts your efficiency:

Efficiency Gains with FHOPEPACK Automation

| Aspect | Manual Process | Automated Process (FHOPEPACK) | Impact |

|---|---|---|---|

| Packing Speed | Slow, inconsistent, dependent on labor availability | Fast, consistent, high-throughput (up to 30 coils/hour) | 🚀 Increased daily output, faster delivery times |

| Labor Usage | High (multiple workers per shift) | Low (1-2 operators for supervision) | 👨🏭 Reduced labor costs, staff redeployment |

| Workflow | Prone to bottlenecks and stoppages | Smooth, continuous, integrated into production line | 📈 Streamlined operations, improved overall factory flow |

| Consistency | Varies with worker skill and fatigue | Uniform, precise wrapping and strapping | ✨ Reduced reworks, higher quality output |

| Setup/Changeover | Time-consuming for different coil sizes | Quick, often automated adjustments | ⏱️ Minimized downtime, greater production flexibility |

(long-tail keywords: automatic steel coil wrapping, high-speed packing solutions, factory throughput improvement, automated industrial packaging, coil packing line integration, reducing production bottlenecks)

2. What Solutions Do FHOPEPACK Offer to Enhance Safety in Coil Handling?

Are you facing serious safety concerns and high injury risks from manual handling of heavy items like steel coils or wire bundles in your factory? The physical demands and potential for accidents are a constant worry, impacting your team’s well-being and driving up insurance costs.

FHOPEPACK offers robust automated coil handling and packing solutions designed to significantly enhance worker safety by minimizing manual interaction with heavy loads, thereby reducing the risk of injuries and creating a much safer working environment in heavy manufacturing settings.

Safety is paramount in any heavy industrial setting, especially where large, weighty items like steel coils are moved and packaged. The traditional reliance on manual labor for these tasks poses significant risks, from muscle strains and sprains to severe crush injuries. At FHOPEPACK, we understand that protecting your workforce is not just a regulatory requirement; it is a fundamental responsibility. Our automated steel coil packing machines are engineered with safety as a core design principle. We replace dangerous manual tasks with mechanical precision.

For example, automated coil handling systems, such as specialized conveyors, transfer cars, and robotic manipulators, move coils without human hands needing to be in the immediate vicinity. This eliminates the need for workers to physically lift, push, or reposition heavy coils, drastically cutting down on the potential for accidents. Our machines often feature safety interlocks, emergency stop buttons, and protective barriers that prevent access to moving parts during operation. Remote control options also allow operators to manage the packing process from a safe distance. For a factory manager like Michael Chen, who grapples with high injury rates and the associated costs and worker turnover, these safety features offer a crucial solution. Investing in automation is not just about efficiency; it is an investment in your team’s health and safety, leading to a more secure and stable workforce. Our goal is to create an environment where your employees can focus on their tasks without constant fear of injury.

FHOPEPACK’s Key Safety Features

Here are some ways our solutions improve safety:

- Automated Conveyance Systems: Eliminate manual lifting and carrying of heavy coils. ➡️ Reduces back injuries and strains.

- Integrated Safety Sensors: Detect unexpected movements or personnel in hazardous zones, triggering immediate shutdowns. 🚨 Prevents collisions and entrapments.

- Protective Guarding and Barriers: Physical barriers prevent operators from reaching moving machinery during operation. 🛡️ Provides a physical shield against moving parts.

- Emergency Stop Mechanisms: Easily accessible E-stop buttons allow for immediate machine shutdown in critical situations. 🛑 Quick response to unforeseen dangers.

- Remote Operation Capabilities: Operators can control machines from a safe distance, away from direct contact with coils. 🎮 Enhances operator safety and comfort.

- Ergonomic Design: Reduces repetitive strain injuries by automating physically demanding tasks. 🧘♀️ Promotes long-term worker health.

(long-tail keywords: industrial safety solutions, automated heavy load handling, worker injury prevention, steel coil safety packing, reducing factory accidents, ergonomic packaging machines, secure steel coil transport)

3. Can FHOPEPACK Machines Help Reduce Product Damage and Operational Costs?

Are you constantly dealing with damaged products, like scuffed steel coil edges, during internal transfer and packaging, leading to frustrating customer complaints and lost profits? The hidden costs of product damage and inefficient operations can significantly erode your factory’s bottom line.

FHOPEPACK machines significantly reduce product damage through precise, automated handling and secure wrapping, while simultaneously cutting operational costs by minimizing labor, reducing material waste, and improving overall process efficiency, delivering clear ROI for your factory.

Product integrity is crucial for customer satisfaction and profitability. When steel coils suffer damage, even minor abrasions or bent edges, during internal handling or packing, it leads to rejects, rework, and costly customer complaints. Our FHOPEPACK packaging machines are designed with meticulous attention to detail to protect your valuable products. The automated process ensures gentle yet firm handling, preventing the kind of bumps and scrapes that often occur with manual methods. Our wrapping machines apply packaging materials with consistent tension, creating a uniform protective layer that shields the coil from external elements and impacts during storage and transit. This precise application prevents slack or overtightened wrapping, which can either leave parts exposed or deform the product.

Beyond preventing damage, FHOPEPACK solutions are engineered to deliver substantial operational cost savings. By automating the packing process, you dramatically reduce the need for manual labor, which is one of the most significant variable costs in manufacturing. Less labor means lower wages, fewer benefits, and reduced overheads. Our machines also optimize the use of packaging materials. Manual wrapping often leads to inconsistencies and waste, with operators using more material than necessary or creating uneven wraps that need redoing. Automated systems, however, are programmed for optimal material usage, ensuring every inch of film or strapping is applied effectively, minimizing waste and procurement costs. Furthermore, by eliminating product damage, you save on replacement costs, return logistics, and the invaluable cost of maintaining a strong customer relationship. The return on investment (ROI) for an FHOPEPACK machine becomes clear as you quantify these reductions in labor, materials, and damage.

Cost-Saving Impact of FHOPEPACK Solutions

| Cost Factor | Manual Operations | FHOPEPACK Automated Solutions | Estimated Savings (Example) |

|---|---|---|---|

| Labor Costs | High, multiple operators for packing & handling | Low, 1-2 operators for supervision | 📉 60-80% reduction in direct labor |

| Packaging Material | Inconsistent usage, potential for waste | Optimized, precise application, reduced waste | ♻️ 10-25% reduction in material use |

| Product Damage | Frequent, due to manual handling and inconsistent wrap | Minimal, due to gentle handling and uniform protection | 💲 90%+ reduction in damage-related losses |

| Worker’s Comp/Safety | High risk of injuries, elevated insurance premiums | Significantly reduced, improved safety record | 🏥 Lower insurance and liability costs |

| Rework/Returns | Common, due to inconsistent quality or damage | Rare, consistent high-quality packaging | 🔄 Minimized rework and customer complaints |

| Throughput Bottleneck | Slow end-of-line, impacting overall production | High-speed, continuous flow, enhancing overall output | 🚀 Increased revenue potential |

(long-tail keywords: reduce steel coil damage, cost-effective packing machines, packaging material optimization, lower operational expenses, return on investment in automation, automatic steel coil strapping, preventing product loss, industrial packaging cost reduction)

4. Why Should Michael Chen Choose FHOPEPACK as a Long-Term Packing Machine Partner?

Have you experienced the frustration of dealing with equipment suppliers who vanish after the sale, leaving you unsupported and disillusioned? Michael Chen, like many factory managers, seeks more than just a vendor; he needs a truly collaborative partner who understands his unique challenges and stands by him for the long haul.

Michael Chen should choose FHOPEPACK as a long-term packing machine partner because my journey as a packing machine engineer, from factory floor to owner, imbues our company with deep, practical industry expertise, ensuring we provide not just machines, but tailored solutions, comprehensive support, and a commitment to shared success that goes beyond a mere transaction.

Choosing a packing machine supplier is a significant decision, and trust is built on much more than just the initial sale. As Randal Liu, the founder of FHOPEPACK, I built this company on a foundation of firsthand experience in the packing machine industry. I started as an employee, learned the ins and outs, and then successfully established my own factory. This journey means I truly understand the pressures Michael Chen faces—from production bottlenecks and safety concerns to the need for durable equipment that performs in demanding environments. We do not just sell machines; we offer insights and solutions derived from years of practical knowledge. My team and I speak your language, understanding the nuances of coil packing and steel wire packing.

Our partnership model focuses on understanding your specific operational challenges and customizing solutions that genuinely address them. This includes thorough consultation, equipment design tailored to your factory layout, professional installation, and comprehensive training for your operators. We believe that proper training empowers your team to maximize the efficiency and longevity of our machines. Furthermore, our commitment extends to robust after-sales support. This means readily available spare parts, prompt technical assistance, and preventative maintenance guidance to ensure your operations run smoothly without unexpected downtime. We are here to help you grow your business, just as I helped many clients achieve their goals. For Michael, who has experienced supplier trust crises, FHOPEPACK offers a refreshing change: a partner dedicated to delivering long-term value, reliability, and expert guidance. We aim to be an extension of your team, a trusted advisor in your pursuit of operational excellence.

Why Partner with FHOPEPACK?

Here are key reasons FHOPEPACK stands out as a long-term partner:

- 🛠️ Deep Industry Expertise: Founded by Randal Liu, a packing machine engineer with hands-on factory experience. This means practical, proven solutions.

- 🤝 Collaborative Problem-Solving: We listen to your specific challenges (like Michael’s efficiency bottlenecks or safety risks) and design tailored solutions, not just off-the-shelf products.

- 💡 Customization & Integration: Our machines are designed to fit your unique production line and factory environment, ensuring seamless integration.

- 👨🏫 Comprehensive Training: We provide thorough training for your operators, ensuring they are proficient and confident in using our equipment for optimal performance.

- ⚙️ Robust After-Sales Support: Expect reliable technical assistance, readily available spare parts, and proactive maintenance advice to minimize downtime.

- 📈 Proven Track Record: My personal history includes helping many clients grow their businesses through effective packing solutions.

- 🌍 Global Reach, Local Understanding: While we serve clients globally, we strive to understand local market needs and operational specifics, offering relevant support.

(long-tail keywords: trusted packaging machine partner, packing machine engineering expertise, long-term supplier relationship, custom industrial packing solutions, comprehensive after-sales support, reliable packing machine supplier Mexico, factory automation consultant, expert packing machine guidance)

Conclusion

FHOPEPACK offers more than just machines; we provide trusted, efficient, and safe steel coil packing line solutions, backed by real-world expertise for your factory’s success.