FHOPE Expands in Mexico with Intelligent Steel Coil Packing System: What Does This Mean for Your Factory?

Do you ever feel the relentless pressure to boost production, slash costs, and keep your team safe, all while managing a complex metal processing operation in Mexico? Many factory managers, like Michael Chen, grapple with these daily challenges. They are constantly looking for reliable, efficient equipment that can withstand the demands of heavy industry.

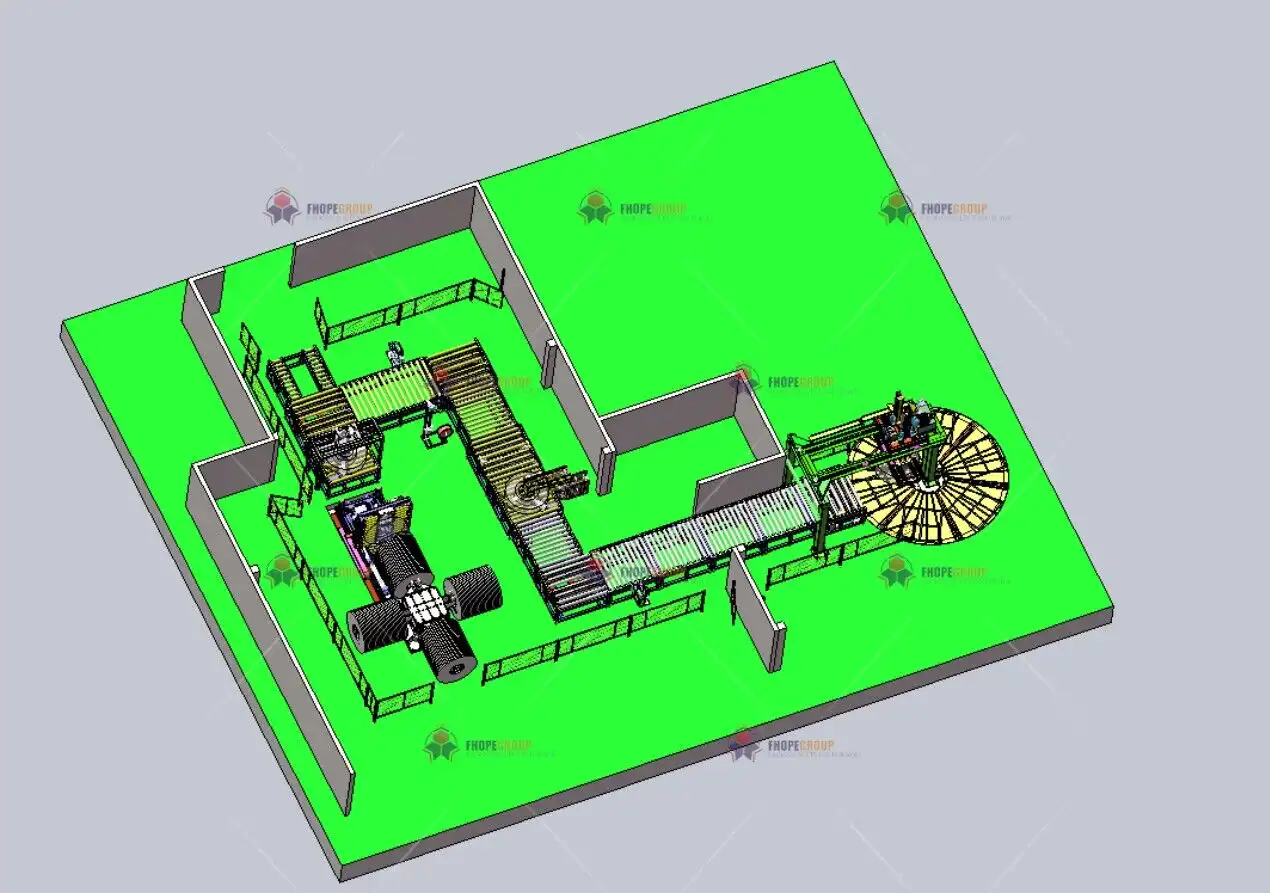

FHOPEPACK is expanding its reach in Mexico with advanced intelligent steel coil packing systems, offering a robust solution designed to address critical operational bottlenecks, enhance worker safety, and significantly reduce product damage in busy manufacturing plants like yours. This expansion means easier access to cutting-edge automation, tailored to the unique needs of the Mexican heavy industry, helping local factories achieve higher efficiency and a stronger competitive edge. (Mexican manufacturing solutions, automated coil packaging, industrial efficiency Mexico)

This isn’t just about selling machinery; it is about building partnerships and providing real solutions. I want to share my journey and FHOPEPACK’s mission to show you how this expansion can benefit your operations. Let’s explore how these intelligent systems are set to transform the steel processing landscape across Mexico.

1. Why is an Intelligent Steel Coil Packing System a Game-Changer for Mexican Factories?

Is your current packing process a bottleneck, holding back your entire production line and slowing down deliveries? Many Mexican factories are still relying on labor-intensive methods for coil and wire packaging. This often leads to slow speeds and low efficiency, which impacts overall output. The frustration of missed deadlines and operational slowdowns is a common experience.

An intelligent steel coil packing system is a game-changer for Mexican factories because it directly addresses the critical issues of slow, manual processes, which are major bottlenecks in production and delivery speed. By automating the end-of-line operations, these systems boost throughput, ensure consistent quality, and reduce the heavy reliance on manual labor, leading to faster, more efficient, and more reliable packaging of steel coils and wire products, making a significant impact on profitability. (steel coil packaging automation, factory bottlenecks Mexico, efficient production lines)

For years, I saw firsthand the struggles in packing machine factories, from the shop floor to managing a successful operation. I know the pain of inefficient processes. That is why FHOPEPACK focuses on intelligent solutions. We understand that in Mexico’s dynamic industrial landscape, every minute of downtime and every slow step costs money. Our systems are designed to integrate seamlessly, turning your packing process from a liability into a competitive advantage. This means less manual effort and more consistent, high-speed output.

The Impact of Automation on Throughput and Delivery

Automation is not just about replacing human hands; it is about optimizing the entire workflow. When I started my own packing machine factory, I quickly learned that manual handling of heavy coils was not only slow but also inconsistent. An intelligent system brings precision and speed that human labor simply cannot match over long periods.

- Increased Speed: Automated systems can pack coils much faster than manual methods. This directly translates to higher daily output.

- Consistent Quality: Machines perform repetitive tasks with exact precision. This means every coil is packed to the same standard.

- Reduced Rework: Manual errors often lead to poorly packed coils that need to be redone. Automation drastically cuts down on these mistakes.

- Optimized Flow: Intelligent systems can communicate with other machines on the line. This creates a smoother, continuous production flow.

- Faster Deliveries: With a quicker packing process, products are ready for shipment sooner. This improves customer satisfaction and helps you meet tight deadlines.

Think about a typical day in a metal processing plant. Michael Chen, for example, is always looking for ways to speed up his operations. If the packing stage is the slowest part, then automating it directly tackles his biggest pain point. This not only makes the factory more productive but also more agile, able to respond to market demands faster. It is about unlocking the true potential of your production line. (industrial automation benefits, faster delivery times, production optimization)

2. How Can Automation Improve Safety and Reduce Product Loss in Steel Processing Plants?

Do your employees face high risks of injury when manually handling heavy steel coils or flipping pallets? This is a serious problem in many heavy industries, leading to soaring insurance costs and high employee turnover. The thought of an accident keeps many factory managers up at night. Beyond safety, are you losing profits due to damaged products during internal transfers and packaging?

Automation significantly improves safety in steel processing plants by minimizing the need for manual handling of heavy and awkward materials like steel coils, drastically reducing the risk of workplace injuries and associated costs. Furthermore, automated systems reduce product loss by providing consistent, gentle, and precise handling during internal transfers and packaging, preventing damage to sensitive areas like coil edges and ensuring products reach customers in perfect condition. (industrial safety solutions, automated material handling, reduce product damage heavy industry)

My journey through the packing machine industry taught me that safety and quality are not just buzzwords; they are fundamental to a successful operation. I have seen the devastating impact of workplace injuries and the financial hit from damaged goods. When I established my factory, prioritizing robust and safe equipment was non-negotiable. FHOPEPACK’s intelligent systems are built on this principle. We aim to protect your most valuable assets: your employees and your products. This means less risk, fewer complaints, and more profit for your business.

Addressing Safety Hazards with Automated Solutions

Worker safety should always be the top priority. Manual handling of heavy coils, especially with traditional methods, is inherently dangerous.

| Safety Hazard | Manual Handling Risks | Automated Solution Benefits |

|---|---|---|

| Ergonomic Strain | Back injuries, muscle strains from lifting/twisting | Robotic arms, conveyors eliminate direct physical lifting |

| Crushing Injuries | Coils falling, hands caught between objects | Sensor-guided movements, restricted access zones |

| Falling Objects | Improper stacking, unsecured loads | Consistent, stable placement, secure clamping mechanisms |

| Repetitive Motion | Carpal tunnel, tendonitis from repetitive tasks | Machines perform monotonous movements tirelessly |

| Fatigue-Related Errors | Accidents due to tired workers | Systems operate consistently without fatigue |

By investing in automated equipment, factories can drastically cut down on these risks. Imagine Michael Chen, overseeing his plant. He constantly worries about his team’s well-being. Implementing automated coil handling and packaging reduces direct human interaction with heavy loads. This creates a much safer work environment, lowers injury rates, and in turn, reduces insurance premiums and employee turnover. It is a win-win for both the business and its people. (workplace safety automation, heavy equipment injury prevention, employee well-being manufacturing)

Minimizing Product Loss and Enhancing Quality

Product damage during handling is a silent killer of profits. Scratched surfaces, dented edges, or misshapen coils lead to customer complaints, returns, and ultimately, lost revenue.

Consider the precision of a machine versus human handling. Even the most careful worker can make a mistake, especially when dealing with heavy, awkward shapes. Automated systems apply consistent force and follow precise pathways.

- Gentle Handling: Automated grippers and conveyors are designed to move coils without dropping or scraping them.

- Consistent Positioning: Every coil is placed exactly where it should be, preventing collisions or uneven stacking.

- Optimized Wrapping: Intelligent systems ensure uniform wrapping tension and coverage. This protects the product from environmental factors and physical damage during transit.

- Reduced Human Error: Less human intervention means fewer chances for accidental drops, bumps, or improper packaging.

I have seen clients struggle with damaged goods, especially steel coil edges. This leads to costly rejections. FHOPEPACK’s systems are engineered to minimize this. For instance, our wrapping machines apply film with controlled tension, protecting the coil without deforming it. This not only saves money but also builds customer trust, a valuable asset for any business, especially for a factory manager like Michael who values long-term partnerships. (product quality control, reduce material waste, automated packaging benefits)

3. What Specific Features Make FHOPEPACK’s Systems Truly "Intelligent" for Heavy Industry?

Have you ever dealt with equipment suppliers who only care about making a sale and then disappear when you need after-sales service? This creates a trust crisis, making factory managers like Michael Chen very cautious when seeking new partners. You need solutions that are truly robust, reliable, and backed by expert support. What makes FHOPEPACK stand out as a trusted partner with intelligent solutions?

FHOPEPACK’s systems are truly "intelligent" for heavy industry because they integrate advanced automation with user-friendly controls, robust construction for demanding environments, and predictive maintenance capabilities, all designed for continuous operation and optimal performance. We build machines that not only automate tasks but also provide data for better decision-making, offering remote diagnostics and customization, ensuring maximum uptime and efficiency in challenging industrial settings. (intelligent industrial machinery, advanced packing automation, heavy-duty equipment features)

When I started FHOPEPACK, I knew we had to be different. My background, from a factory employee to factory owner, taught me the immense value of reliable equipment and genuine partnership. I built my business on trust and delivering real value. This means our "intelligent" systems are not just loaded with technology; they are engineered for the harsh realities of factories like Michael’s. We focus on durability, ease of use, and comprehensive support, making sure your investment truly pays off.

Key Intelligent Features of FHOPEPACK Systems

Our intelligent systems are designed with the unique needs of heavy industry in mind, focusing on reliability, efficiency, and smart operation.

Smart Automation & Integration:

- ⚙️ PLC Control: Siemens or Allen-Bradley PLCs ensure precise and reliable operation. This allows for complex motion control and seamless integration with existing factory lines.

- 📊 HMI Touchscreen: Intuitive interfaces make operation easy. Operators can monitor status, adjust settings, and diagnose issues quickly.

- 🔗 IoT Connectivity: Machines can connect to the internet, allowing for remote monitoring, data collection, and software updates. This is crucial for proactive maintenance.

- 🤖 Robotic Integration: Our systems can incorporate robotic arms for specific tasks like coil handling or label application, increasing flexibility and reducing human intervention.

Robust Design for Harsh Environments:

- 💪 Heavy-Duty Construction: Built with reinforced steel frames and industrial-grade components to withstand continuous operation in harsh conditions.

- 🛡️ Dust and Water Resistance: Enclosures and components are protected against dust, moisture, and corrosive elements commonly found in metal processing plants.

- 🌡️ Temperature Resilience: Designed to perform reliably across a wide range of operating temperatures, ensuring stability even in challenging factory environments.

Data-Driven Optimization & Support:

- 📈 Production Data Logging: Systems record operational data such as coils packed per hour, film consumption, and error logs. This data is vital for performance analysis and continuous improvement.

- 🚨 Predictive Maintenance: Sensors monitor component wear and tear. The system can predict potential failures before they happen, scheduling maintenance proactively.

- 📞 Remote Diagnostics & Support: Our team can remotely access the machine’s control system for troubleshooting and support. This minimizes downtime and travel costs.

- 🔧 Customization: We don’t just sell standard machines. We work with clients like Michael to customize solutions that fit their exact production needs and facility layout.

Michael Chen values equipment reliability above all else. He has seen the cost of downtime. Our intelligent features like predictive maintenance and remote diagnostics directly address this. By providing tools to prevent failures and quickly resolve issues, FHOPEPACK builds the trust that many suppliers have lost. This proactive approach ensures continuous operation and maximum return on investment. (predictive maintenance solutions, industrial IoT packing, customizable packaging machinery)

4. How Does FHOPEPACK Partner with Factories Like Michael’s to Ensure a High ROI?

Are you looking for a partner who truly understands your production challenges, safety concerns, and efficiency needs? Do you want more than just a machine; you want a reliable solution provider? Michael Chen, like many factory managers, seeks professional guidance from experts with deep industry knowledge and proven experience. He wants to ensure that his investment in new equipment yields a clear and significant return.

FHOPEPACK partners with factories like Michael’s by offering comprehensive, expert guidance rooted in deep industry experience, ensuring that every investment in our intelligent steel coil packing systems delivers a high Return on Investment (ROI). We provide tailored solutions, conduct thorough site assessments, offer robust after-sales support, and focus on long-term value, moving beyond just selling equipment to truly understanding and solving client-specific production bottlenecks and safety challenges. (ROI industrial equipment, expert packing solutions, factory partnership program)

When I started FHOPEPACK, I aimed to be more than just a vendor. Having built and run my own packing machine factory, I understand the client’s perspective deeply. I know that a machine is only as good as the support and expertise behind it. We listen to your challenges, like Michael’s need for greater automation and improved safety. Our goal is to provide solutions that not only solve immediate problems but also drive long-term business growth and profitability. This is about trust, shared success, and a commitment to your factory’s future.

FHOPEPACK’s Partnership Approach for Maximizing ROI

Our approach to partnership goes beyond the initial sale. We view ourselves as an extension of your team, committed to your success.

-

In-depth Consultation & Needs Assessment:

- Understanding Your Operations: We start by deeply understanding your current processes, bottlenecks, and specific challenges, just like Michael’s struggles with efficiency and safety.

- Site Visits & Analysis: Our experts can visit your Mexican factory to assess the layout, existing equipment, and operational flow.

- ROI Projections: We work with you to calculate the potential return on investment, detailing how our solutions will reduce labor costs, minimize waste, and increase throughput.

- Custom Solution Design: We don’t offer one-size-fits-all. Instead, we design a system tailored to your unique requirements, ensuring it integrates perfectly with your production line.

-

Turnkey Project Management:

- Installation & Commissioning: Our skilled engineers handle the complete installation and ensure the system is commissioned correctly and safely.

- Operator Training: We provide thorough training for your factory staff, ensuring they can operate and maintain the new equipment efficiently and safely.

- Production Ramp-up Support: We stay with you during the initial production phase to optimize settings and address any unforeseen issues, guaranteeing a smooth transition.

-

Comprehensive After-Sales Support:

- Technical Assistance: Our support team is available to help with any technical queries or operational issues that arise.

- Spare Parts Availability: We ensure a ready supply of spare parts, minimizing downtime during maintenance or repairs.

- Preventative Maintenance Plans: We offer tailored maintenance plans to keep your equipment running at peak performance, prolonging its lifespan and preventing costly breakdowns.

- Continuous Improvement: We provide ongoing advice and updates, helping you evolve your system as your factory’s needs change.

Michael Chen explicitly seeks a partner with deep industry background and successful factory-building experience. That’s exactly what I offer with FHOPEPACK. My experience has shown me that true ROI comes from a combination of excellent machinery and an unwavering commitment to the client’s success. We ensure that our intelligent systems not only solve today’s problems but also lay the groundwork for future growth and profitability. (long-term equipment partnership, factory efficiency consulting, industrial machinery ROI calculation)

Conclusion

FHOPEPACK’s intelligent steel coil packing systems offer Mexican factories a clear path to enhanced efficiency, safety, and profitability. Partnering with us means investing in solutions designed for high ROI and backed by expertise, ensuring your operations thrive with our steel coil packaging line.