Ever Found Yourself Wondering How to Safely Turn Over Massive Dies or Molds?

Ah, the workshop floor. For three decades, I’ve navigated the hum and clatter of mechanical and electrical automation, witnessing firsthand the evolution of manufacturing processes. One persistent challenge, particularly in metal stamping, die casting, and plastic injection molding, has always been the handling of heavy, cumbersome dies and molds. These aren’t just lumps of metal; they’re precision instruments, often representing significant investment. Flipping them for maintenance, setup, or storage using cranes and chains? It’s always struck me as a precarious ballet, fraught with risks – risks to personnel and risks to the tooling itself. That’s where dedicated equipment, specifically designed for this task, becomes not just a convenience, but a cornerstone of safe and efficient operation. We’re talking about die upenders, sometimes called mold flippers or tippers. They are the unsung heroes that simplify what can otherwise be a nerve-wracking procedure. Let’s delve into why these machines are so pivotal.

So, What Exactly Does a Die Upender Achieve?

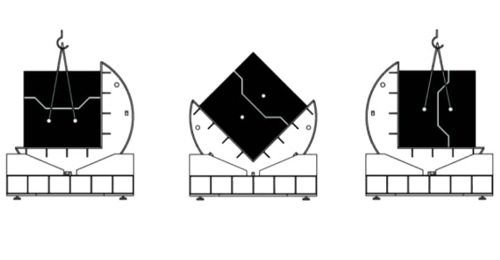

Imagine needing to inspect or work on the underside of a multi-ton die. Traditionally, this involved complex rigging, multiple personnel, and a significant element of hope that nothing slips. A die upender fundamentally changes this dynamic. Its core purpose is elegantly simple: to rotate a heavy load, typically a die or mold, through a full 90 degrees, smoothly and safely.

See What This Die Upender Has to Offer.

Take a moment to visualize this in action. The video below gives a great sense of the controlled power involved.

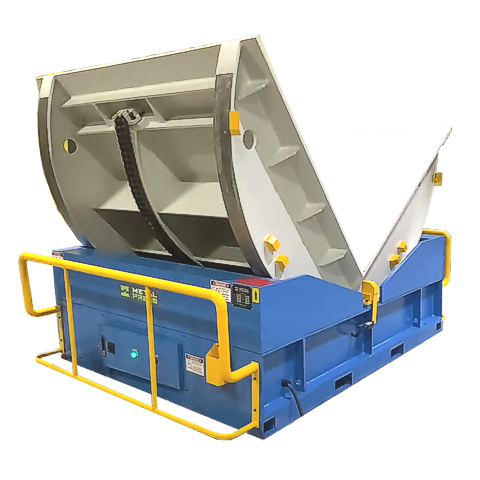

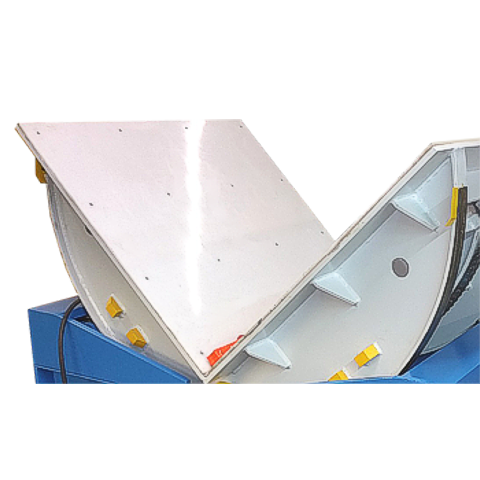

Notice the robust design, the controlled motion. It’s not just about turning something over; it’s about doing so with precision and repeatability. Operator safety, minimizing setup time, and delivering tangible value – these are the driving forces behind effective upender design. They come in various sizes, naturally, to accommodate the vast spectrum of tooling weights and dimensions found across industries.

How Does It Manage a Full 90° Rotation So Smoothly?

The magic lies in the mechanics and thoughtful engineering. These machines are designed for flexibility – a full 90-degree rotation isn’t just a target, it’s a precisely controlled journey. Critically, the rotation is smooth and can be initiated, paused, or stopped at any point along its arc, in either direction. This level of control is paramount when dealing with potentially unbalanced or extremely heavy loads. You don’t want sudden jerks or uncontrolled momentum; you need deliberate, predictable movement. This capability allows for inspection or minor adjustments even mid-rotation, offering a degree of operational flexibility that traditional lifting methods simply can’t match safely.

What Makes These Machines a Smart Choice for Heavy-Duty Tasks?

From my years on the floor, I can tell you that equipment ROI isn’t just about purchase price; it’s about reliability, ease of use, maintenance, and, crucially, safety. Die upenders tick these boxes compellingly. They represent a significant leap in productivity simply by streamlining a previously complex and time-consuming task. More importantly, they vastly enhance workplace safety by removing personnel from the immediate vicinity of a potentially hazardous flipping operation.

Think beyond just dies and molds. I’ve seen these versatile machines, often referred to broadly as tippers or flippers, handle large steel coils, bulky fabrications, and other challenging loads that require reorientation. The principle remains the same: provide a stable, controlled 90-degree rotation.

Key characteristics I always look for and appreciate in these designs include:

- Stalwart Construction: These aren’t flimsy gadgets. They need a solid, robust build to handle immense weight day in and day out.

- All-Electric Operation: A preference for many, including myself, due to its cleanliness and generally simpler maintenance compared to hydraulics.

- User-Friendliness: Controls should be intuitive, minimizing training time and operator error.

- Speed of Operation: Efficiency matters. A quick cycle time translates directly to productivity gains.

- Simplified Maintenance: Easy access to components and straightforward upkeep procedures reduce downtime.

- Inherent Safety: Designed from the ground up with operator protection in mind.

- Reduced Manual Handling: Minimizes the risks associated with physically manipulating heavy loads.

- Versatility: Applicable to dies, molds, coils, and other unwieldy items.

- Bidirectional 90° Flip: Offers maximum flexibility in positioning.

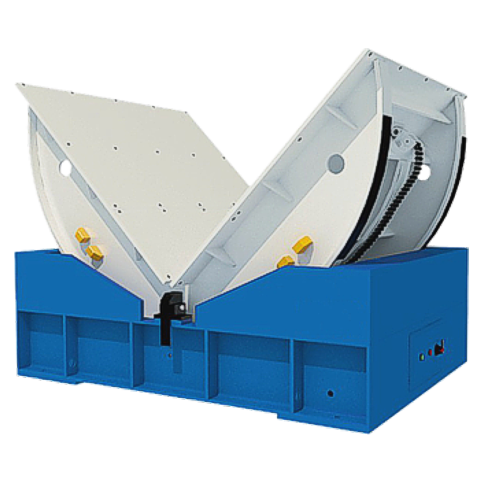

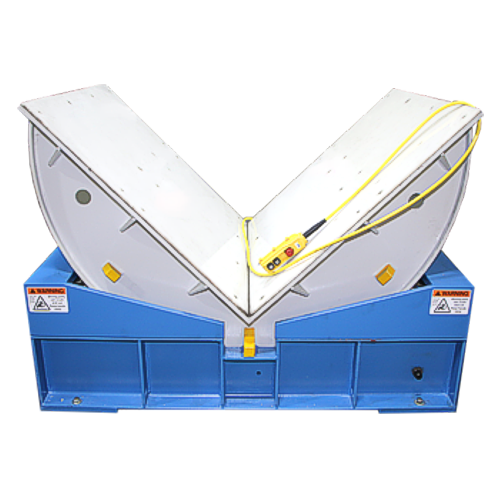

Take a look at these images – they showcase the typical robust structure and the kind of loads these machines are designed to handle.

(Duplicate images removed for brevity in this thought process, but would be retained in the final output per instructions)

Can the Construction Truly Withstand Constant Industrial Use?

Absolutely. The foundation of a reliable upender is its construction. We’re talking about heavy-gauge, reinforced, welded steel structures. The driving force is typically a gear motor coupled with a robust dual chain and sprocket system – a tried-and-true method for delivering high torque and controlled rotational movement. The load rests on two flat, sturdy platforms forming the cradle. To handle the immense forces involved, heavy-duty sealed bearings are essential for the rollers supporting the load’s rotation. A critical element I always appreciate is the inclusion of a brake motor and gear reducer. This combination ensures that the rotation cycle is smooth, preventing any jarring starts or stops or sudden shifts in speed that could destabilize the load – a crucial safety and operational feature when you’re dealing with tons of steel.

Why Opt for All-Electric? Aren’t Hydraulics Powerful?

Hydraulics certainly offer power, but in my experience, electric systems bring distinct advantages to the table for this specific application. The core of the electric system is often a gear motor driving that dual chain sprocket mechanism I mentioned. It delivers smooth, consistent, and highly controllable rotation.

The major benefit? No hydraulics means no hydraulic fluid, no potential leaks, no burst hoses, and generally cleaner operation and simpler maintenance routines. In environments where cleanliness is important, or where minimizing potential fluid spills is a priority, an all-electric system is often the preferred choice. The reliability of modern electric motors and gearboxes is exceptional, making them a very dependable powerhouse for these machines.

How is Worker Safety Ensured During Operation and Maintenance?

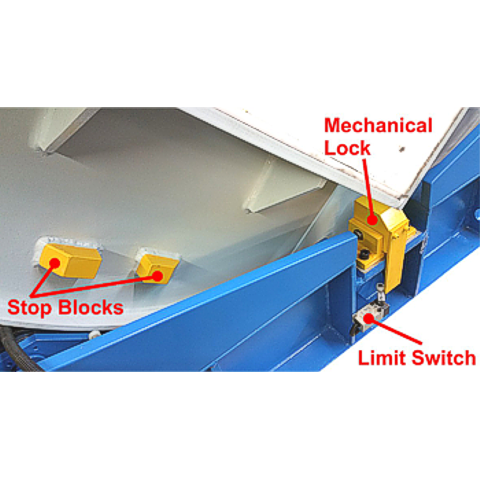

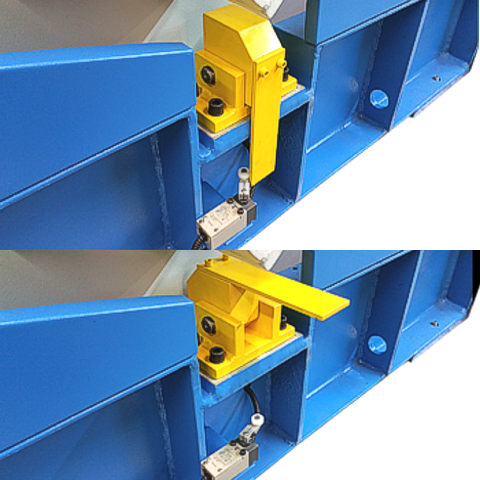

Safety isn’t just a feature; it’s a fundamental requirement when dealing with machinery capable of moving such heavy loads. A critical baseline safety measure I always look for is a robust mechanical locking pin system. These pins are engaged during cleaning or maintenance activities, physically preventing the machine’s tables from moving unexpectedly. It’s a simple, yet highly effective, failsafe. Layered on top of this physical lock are electronic limit switches. These serve as a secondary check, confirming the status of the safety system and electrically disabling the upender’s startup sequence if the pins aren’t correctly engaged or if other safety conditions aren’t met. It’s this layered approach – mechanical and electrical – that provides genuine peace of mind.

Are There Options for Enhancing Safety Further?

Yes, beyond the standard features, there are often options to augment safety based on the specific operational environment.

Safety Rails: For added physical containment, optional safety rails can often be fitted to both ends of the upender. These act as barriers, helping to define the machine’s working envelope more clearly and providing an extra layer of protection.

Laser Safety Systems: For facilities requiring a higher level of active safety monitoring, sophisticated options like safety laser scanners are available. These devices typically use time-of-flight technology, constantly scanning the area around the machine.

They work in real-time, calculating distances based on laser pulses bouncing off objects. Predefined safety zones can be programmed – usually a warning zone and a stop zone. If a person or object (like a forklift) enters the warning zone, an alert might sound. If they breach the inner stop zone, the scanner instantly signals the upender to halt its operation. These zones are highly configurable to match the specific layout and workflow around the machine. Some systems even offer optional cameras to record events that trigger a shutdown, which can be invaluable for incident analysis and training. In high-traffic areas or where automated guided vehicles (AGVs) operate, such systems provide a dynamic and intelligent safety layer.

What About Protecting the Die or Mold Itself?

Dies and molds are often high-value assets with precisely machined surfaces. Protecting them, as well as the upender’s tables, is a valid concern. One practical option I’ve seen used effectively is the addition of removable surface covers, often made from a durable material like polycarbonate.

These covers are typically screwed onto the metal table surfaces. They provide a sacrificial layer, absorbing minor impacts and preventing scratches or damage to both the tooling resting on the table and the table itself. It’s a relatively simple addition that can significantly extend the life of valuable assets and maintain the condition of the equipment.

Can the Upender’s Functionality Be Made Even More Flexible?

Standard upenders perform their core task admirably, but certain operational needs might call for enhanced flexibility. Two options stand out:

Full 180° Rotating Base: Imagine placing a die onto the upender with a forklift from one side, rotating the die 90 degrees, and then needing to access it or pick it up from a different angle without moving the forklift around the entire machine. An optional 180-degree rotating base allows the entire upender unit (after it has potentially flipped the load) to rotate horizontally.

This significantly reduces the need for complex forklift maneuvers or manual repositioning of the heavy tooling around the machine. It streamlines workflow, speeds up turnaround times, and improves overall efficiency, especially in busy tool rooms or maintenance areas. The controlled movement also enhances safety during these repositioning phases.

Forklift Base: While many upenders are installed in a fixed location, some facilities require the flexibility to move the unit between different work cells or areas. For these scenarios, an optional base specifically designed with integrated forklift pockets is invaluable.

This allows the entire upender to be safely and easily transported using a standard forklift to wherever it’s needed most. This mobility is particularly advantageous in large facilities with multiple press lines or molding machines, maximizing the utility of the investment across different operational zones.

How Do I Know What Size or Capacity I Might Need?

This is a critical question, as underspecifying or overspecifying can be inefficient. These mechanical upenders are typically available in a wide range of standard capacities, designed to cater to diverse industrial requirements. The spectrum generally starts from units capable of handling around 5.5 tons (or 5,000 kg) – suitable for smaller tooling – and extends impressively upwards to models designed for truly massive loads, sometimes exceeding 77 tons (or 70,000 kg).

The key is to accurately assess the maximum weight, the dimensions (length, width, height), and critically, the center of gravity of the loads you intend to handle. Manufacturers usually provide detailed specifications regarding table size, maximum weight capacity, and the acceptable center of gravity envelope for each model size. Matching your specific application’s requirements to the machine’s capabilities is essential for safe and effective operation. Consulting with experienced suppliers or engineers is always advisable to ensure you select the right capacity and table size for your needs. While the original provided specific tables, the crucial takeaway is the existence of this wide range, ensuring a fit for almost any conceivable industrial die, mold, or similar heavy load flipping task.

Is Investing in an Upender Truly Necessary for My Operation?

It’s a fair question, especially when budgets are tight. For years, many operations relied on cranes, chains, and manual effort. However, "making do" often comes with hidden costs – increased risk of accidents, potential damage to expensive tooling, longer changeover times, and lower overall efficiency.

There’s actually a wealth of information exploring this very topic. If you’re contemplating whether the investment makes sense, delving deeper into the arguments for using dedicated upenders can be enlightening. Considerations usually revolve around:

- Quantifiable Safety Improvements: Reducing near misses and recordable incidents related to load handling.

- Tooling Protection: Avoiding costly damage from uncontrolled flipping or dropping.

- Efficiency Gains: Dramatically reducing the time and labor required for turning operations.

- Ergonomics: Improving working conditions for maintenance and setup crews.

- Process Standardization: Ensuring a consistent, repeatable, and safe method for handling heavy items.

Exploring resources like whitepapers can provide structured arguments and data points to help justify the investment.

Consider this resource for deeper insights

How Do These 90-Degree Mechanical Upenders Compare to Other Handling Solutions?

The 90-degree all-electric mechanical upender occupies a specific and valuable niche, but it’s helpful to understand how it fits within the broader landscape of heavy load manipulation equipment:

- Hydraulic Upenders/Tippers: These perform a similar 90-degree rotation but use hydraulic cylinders as the driving force.

- Pros: Can offer very high force density, potentially simpler design in some high-capacity cases.

- Cons: Require hydraulic power units, potential for leaks, fluid maintenance, potentially less precise speed control compared to electric drives with VFDs (Variable Frequency Drives).

- 180-Degree Inverters: These machines rotate the load a full 180 degrees.

- Pros: Allow complete access to the opposite side of the load without needing a second flip. Useful for tasks requiring work on both top and bottom surfaces consecutively. Can sometimes clamp the load for added security during inversion.

- Cons: More complex mechanism than a 90-degree tipper, potentially larger footprint, higher cost. Often application-specific (e.g., handling stacks of materials, certain types of mold maintenance).

- Coil Upenders/Positioners: While some general upenders can handle coils, specialized coil upenders are designed specifically for tilting metal coils between "eye-to-the-sky" (vertical) and "eye-to-the-horizon" (horizontal) orientations.

- Pros: Feature cradles or platforms specifically shaped to securely support coils, preventing damage and ensuring stability. Optimized for the unique geometry and handling needs of coiled materials.

- Cons: Less versatile for handling non-coil loads like large rectangular dies or molds.

- Manual Flipping (Cranes, Chains, Forklifts): The traditional method.

- Pros: Utilizes existing equipment (cranes, forklifts). Lower initial capital outlay if suitable lifting equipment is already available.

- Cons: Significantly higher risk of accidents and load damage. Requires skilled riggers and operators. Much slower and less efficient. Difficult to achieve controlled, smooth rotation. Places personnel in potentially hazardous positions.

- Die Splitters/Separators: These machines are specifically designed to safely separate the upper and lower halves of a mold or die set, often incorporating a tilting function for one half.

- Pros: Purpose-built for die/mold maintenance, offering precise control over separation and often providing easy access for cleaning, repair, or component replacement. Can include safety features specific to die handling.

- Cons: Primarily focused on separation and maintenance access, not just general 90-degree flipping for storage or transport orientation. Less versatile for other types of loads.

In essence, the 90-degree all-electric mechanical upender strikes a balance. It offers significantly enhanced safety and efficiency over manual methods, provides robust and versatile 90-degree rotation suitable for a wide range of dies, molds, and other heavy objects, and achieves this with the clean, reliable operation of an electric drive system. For many common industrial tasks involving reorienting heavy tooling or workpieces, it represents a highly effective and increasingly indispensable solution. My decades in this field have shown me time and again: investing in the right tool for the job, especially when it comes to safety and handling heavy loads, pays dividends far beyond the initial cost.

![8 Critical Factors When Choosing a Wire Coil Wrapping Machine [2025 Buyer’s Guide] 8 Critical Factors When Choosing a Wire Coil Wrapping Machine [2025 Buyer’s Guide]](https://i0.wp.com/www.fhopepack.com/blog/wp-content/uploads/2023/01/Master-coil-stretch-wrapper-zt.webp?w=1024&resize=1024,1024&ssl=1)