Entry-Level Steel Coil Packing Machine vs High-End Solutions — Performance Comparison?

In the demanding world of heavy industry, efficiency and safety are not just buzzwords; they are critical for survival and growth. Many factory managers, like my friend Michael in Mexico, face daily pressures to boost output, control costs, and keep workers safe. I’ve seen firsthand how outdated packing methods can create bottlenecks, lead to injuries, and chip away at profits. It’s a constant struggle to balance immediate operational needs with long-term investment strategies.

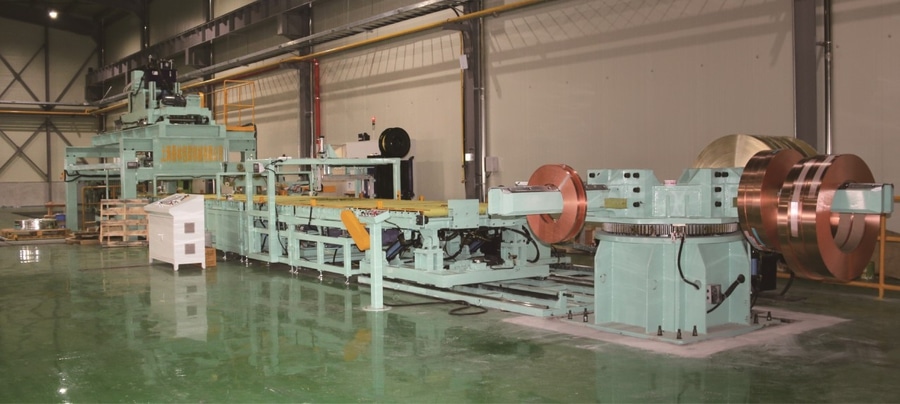

Choosing the right steel coil packing machine is a pivotal decision that directly impacts your entire production line, from throughput to worker safety and overall profitability. The primary difference between entry-level and high-end solutions lies in their capacity for automation, durability, integration capabilities, and the inherent value they deliver in terms of sustained performance and operational savings over time. (steel coil packing machine comparison)

Making a significant investment in factory equipment requires careful thought. You need solutions that not only fit your budget but truly address your operational challenges and contribute to your business’s success. Let’s explore the key differences between these packing machine categories so you can make an informed choice for your specific needs, much like I’ve helped many clients optimize their operations.

1. What Defines an Entry-Level Steel Coil Packing Machine?

When you first consider automating your packing process, entry-level machines often catch the eye due to their appealing initial price point. They seem like a quick fix, promising to solve some immediate problems without a heavy upfront investment. However, my experience in the packing machine industry has taught me that the true cost of equipment extends far beyond the purchase price.

Entry-level steel coil packing machines are typically designed for basic, low-volume packing tasks, offering essential functionalities like simple wrapping or banding without extensive automation or sophisticated integration features. They are best suited for operations with less demanding production schedules and lower daily output requirements, where manual intervention remains an acceptable part of the workflow. (basic coil packing solutions)

Core Characteristics of Entry-Level Machines

Entry-level machines usually come with a straightforward design and limited features. They focus on performing one or two specific packing tasks. This often means less complexity in operation, which can be good for small teams or those new to automation. However, this simplicity often comes with trade-offs in terms of speed, versatility, and long-term durability. For example, many entry-level coil wrappers might require manual loading and unloading, or manual adjustments for different coil sizes. This can still leave you with efficiency bottlenecks and safety risks, especially if you’re dealing with heavy steel coils that require careful handling. I often see factories struggling with high labor costs and increased product damage due to these limitations. These machines are a stepping stone, but they are rarely the final solution for a growing factory.

- Limited Automation: Most entry-level machines still require significant manual intervention for loading, unloading, and process adjustments. This can include tasks like applying packing materials, cutting, and sealing.

- Lower Throughput: Designed for smaller volumes, their operational speed is generally slower. This makes them less suitable for factories like Michael’s, which face high production demands and tight delivery schedules.

- Basic Construction: Often built with less robust materials or simpler engineering, leading to a shorter lifespan under continuous, heavy-duty use. This can result in more frequent breakdowns and higher maintenance costs over time.

- Minimal Safety Features: While they meet basic safety standards, advanced safety interlocks, automated fault detection, and integrated safety fencing might be missing, increasing the risk for workers involved in manual processes.

- Lack of Integration: They typically operate as standalone units, making it difficult to integrate them into an existing automated production line or connect with factory management systems. This limits overall workflow optimization.

- Lower Initial Cost: This is their main advantage, offering an accessible entry point for businesses with tight budgets or very specific, low-volume needs. However, the total cost of ownership needs careful consideration.

Let’s consider Michael’s challenges. His current steel coil packing process relies heavily on manual labor, leading to slow speeds and low efficiency. An entry-level machine might automate one step, but it might not solve the larger issue of his production bottleneck. The lower durability might mean more downtime, which, as Michael knows, translates to significant financial losses. While they offer a lower entry point, it’s vital to see if they align with long-term goals of enhanced safety, increased efficiency, and reduced product loss. (entry-level packing machine limitations)

2. What Makes High-End Packing Solutions Superior for Heavy Industry?

For factories operating in heavy industry, where robust materials and continuous output are the norm, high-end packing solutions are not merely an upgrade; they are an essential investment. These systems are engineered to meet the rigorous demands of environments like Michael’s metal processing plant, addressing challenges that entry-level machines simply cannot overcome. My journey from a packing machine engineer to founding FHOPEPACK has shown me that true value comes from reliability and performance under pressure.

High-end steel coil packing solutions are distinguished by their advanced automation, robust construction, comprehensive safety features, and ability to seamlessly integrate into complex industrial production lines. They are designed for continuous, high-volume operation, offering superior efficiency, minimal downtime, and significant long-term cost savings through reduced labor, waste, and improved product protection, making them ideal for heavy industry demands. (advanced coil packaging systems)

The Unmatched Value of Advanced Systems

High-end packing machines represent the pinnacle of packing technology. They are built for endurance, precision, and peak performance, critical factors for factories handling heavy, valuable products like steel coils or steel wire packing. These solutions are not just about wrapping a coil; they are about optimizing the entire end-of-line process. They integrate features that protect your workers, minimize product damage during handling, and streamline your operations to an extent that entry-level machines cannot. This means addressing Michael’s biggest concerns: improving safety by drastically reducing manual handling of heavy coils, eliminating efficiency bottlenecks with fast and consistent packing, and protecting product integrity to reduce customer complaints. The initial investment might be higher, but the return on investment (ROI) is often much clearer and more substantial due to the drastic improvements in operational efficiency and safety.

- Full Automation & Integration: These systems offer complete automation, from automatic feeding and wrapping to labeling and stacking. They integrate smoothly with existing production lines and even ERP systems, creating a cohesive, smart factory environment. This directly addresses Michael’s goal of elevating automation to solve end-of-line bottlenecks.

- Heavy-Duty Construction & Durability: Constructed with industrial-grade components and robust engineering, high-end machines are designed to withstand the harsh conditions of heavy manufacturing. This ensures a longer operational lifespan and significantly reduces the likelihood of unexpected breakdowns, offering reliability that is crucial for Michael’s plant.

- Enhanced Safety Protocols: Incorporating advanced safety features like light curtains, interlocked guarding, emergency stops, and automated fault detection minimizes human interaction with dangerous machinery. This helps prevent workplace accidents, reducing insurance costs and improving worker retention, a key objective for Michael.

- Superior Efficiency & Throughput: Capable of processing a much higher volume of coils at faster speeds with consistent quality, these machines dramatically improve production efficiency. They are engineered to maximize uptime and minimize manual adjustments, ensuring a smooth and uninterrupted workflow.

- Product Protection & Quality Control: With precise tension control, customized wrapping patterns, and gentle handling mechanisms, high-end systems minimize product damage, such as bent edges on steel coils. This ensures products arrive at the customer in pristine condition, reducing complaints and losses.

- Lower Total Cost of Ownership (TCO): While the initial investment is higher, the TCO is often lower due to reduced labor costs, less product waste, fewer maintenance issues, and increased production capacity. This provides a clear and attractive ROI for factory managers focused on profitability. (heavy-duty packing solutions ROI)

3. How Do Performance Metrics Differ Between Entry-Level and High-End Systems?

When evaluating packing machines, looking beyond the sticker price is critical. True performance is measured by how well a machine contributes to your factory’s overall output, reliability, and cost-effectiveness over its lifespan. For someone like Michael, who has overseen operations for two decades, these metrics are the real indicators of success. It’s about understanding the long-term impact on your business.

The performance metrics between entry-level and high-end steel coil packing machines diverge significantly across key areas like speed, reliability, operational costs, and safety integration. High-end systems consistently deliver superior throughput, greater operational stability with minimal downtime, lower per-unit packing costs, and significantly enhanced worker safety through advanced automation, making them a more robust and cost-effective choice for demanding industrial environments. (packing machine performance metrics)

A Direct Comparison of Operational Effectiveness

Let’s break down the tangible differences in performance that can impact your factory day in and day out. I’ve compiled this table based on years of observing various setups and helping factories like Michael’s transition from manual to automated processes. These differences directly translate into your bottom line and the safety of your workforce.

| Feature / Metric | Entry-Level Coil Packing Machine | High-End Coil Packing Solution | Impact for Factory Managers (e.g., Michael) |

|---|---|---|---|

| Throughput (Coils/Hour) | 5-15 coils (manual assistance needed) | 20-60+ coils (fully automated) | 📈 Efficiency: Direct impact on production capacity and delivery times. High-end resolves bottlenecks. |

| Reliability / Uptime | Moderate; higher risk of breakdowns due to simpler parts | High; robust components, minimal unplanned downtime | 📉 Downtime Costs: Reduced production losses; critical for meeting quotas. |

| Operational Labor | High; requires multiple operators for loading/unloading | Low; minimal supervision, frees up workers for other tasks | 💰 Cost Savings: Significant reduction in labor expenses over time. |

| Safety Features | Basic guards, manual interaction points | Advanced interlocks, light curtains, auto fault detection | ✅ Worker Safety: Drastically lowers accident risk, improves morale. |

| Product Damage | Higher risk during manual handling or inconsistent wrapping | Minimal; precise handling, consistent wrapping tension | 🛡️ Profit Protection: Fewer customer complaints, less material waste. |

| Integration | Standalone unit, no data exchange | Seamlessly integrates with MES/ERP, data logging | 📊 Data & Control: Better process monitoring and optimization capabilities. |

| Maintenance Needs | Can be frequent for minor issues, parts may be basic | Less frequent, but requires specialized technician for major repairs | 🔧 Maintenance Burden: Predictable schedules, higher quality parts last longer. |

| Lifespan | 5-10 years (under moderate use) | 15-20+ years (even under heavy industrial use) | 🔄 Investment Value: Longer asset life, better long-term ROI. |

It is clear that for a factory manager dealing with high production volumes and strict safety protocols, the high-end option delivers far superior performance. While the initial cost of an entry-level machine might be less, the accumulated costs from lower efficiency, increased labor, higher risk of accidents, and potential product damage can quickly erode any perceived savings. High-end solutions are built to operate continuously, reliably, and safely, addressing core challenges like Michael’s efficiency bottlenecks and safety concerns. This ensures that the investment pays off not just in speed, but in peace of mind and sustained profitability. (coil packing machine ROI comparison)

4. Why Invest in Advanced Packing Technology for Long-Term Factory Growth?

For a factory manager like Michael, the decision to invest in new equipment is a strategic one, looking beyond immediate needs to future-proof the business. My own journey, building a successful packing machine factory from the ground up, showed me that smart investments in technology are the bedrock of sustainable growth. It’s not just about today’s profits, but about building a resilient and competitive operation for tomorrow.

Investing in advanced steel coil packing technology is a strategic move for long-term factory growth because it addresses fundamental operational challenges, provides a clear return on investment through reduced costs and increased efficiency, enhances worker safety, and establishes a foundation for future automation and competitiveness. It transforms packing from a bottleneck into a core strength, driving sustained profitability and securing market leadership. (advanced packing technology investment)

Securing Your Factory’s Future with Smart Automation

The benefits of advanced packing technology extend far beyond the packing line itself. They touch every aspect of your business, from your balance sheet to your reputation with clients and your employees’ well-being. This is precisely what Michael seeks: not just a machine, but a partner and a solution that truly understands his operational bottlenecks, safety hazards, and efficiency challenges. A high-end solution, especially when supported by a knowledgeable partner like FHOPEPACK, can provide the professional insights and reliable solutions that truly drive business growth. It’s an investment in your company’s future, ensuring it remains efficient, safe, and profitable.

- Significant Cost Reduction:

- Labor Savings: Automating labor-intensive processes drastically reduces the need for manual packing staff, leading to substantial savings in wages, benefits, and training costs.

- Reduced Product Loss: Precision handling and consistent wrapping minimize damage to valuable products like steel coils or steel wire packing, cutting down on waste and customer returns.

- Lower Insurance Premiums: Enhanced safety features and fewer workplace accidents can lead to reduced workers’ compensation claims and lower insurance costs.

- Boosted Operational Efficiency:

- Increased Throughput: High-speed, continuous operation ensures that packing keeps pace with production, eliminating end-of-line bottlenecks and speeding up delivery times.

- Improved Workflow: Seamless integration with other factory systems allows for optimized material flow and better overall production planning, maximizing uptime.

- Consistent Quality: Automated processes deliver uniform packing quality every time, enhancing product presentation and customer satisfaction.

- Unparalleled Worker Safety:

- Minimized Manual Handling: Removing the need for human interaction with heavy coils during packing significantly reduces the risk of serious injuries.

- Controlled Environment: Advanced safety features create a secure working zone, protecting employees from moving machinery parts and operational hazards.

- Compliance with Regulations: Investing in modern equipment ensures adherence to the latest safety standards, preventing costly fines and legal issues.

- Stronger Supplier Partnerships:

- Expert Guidance: Working with a supplier like FHOPEPACK, with deep industry background and factory-building experience, means getting solutions tailored to your specific problems.

- Reliable Support: A reputable supplier offers excellent after-sales service, spare parts availability, and technical support, building trust and ensuring long-term operational success. This directly addresses Michael’s past "supplier trust crisis."

- Customized Solutions: High-end providers can offer bespoke solutions that fit unique factory layouts and production requirements, ensuring maximum effectiveness.

- Enhanced Competitiveness:

- Market Advantage: A highly efficient and safe operation allows for faster turnaround times and consistent product quality, giving you an edge over competitors.

- Future-Proofing: Investing in flexible, scalable advanced technology prepares your factory for future market demands and technological advancements, ensuring continued relevance.

By strategically investing in advanced packing technology, factories can transform their operations, achieve measurable cost savings, create a safer working environment, and secure a prominent position in the competitive heavy industry landscape. This type of forward-thinking investment is what propels businesses forward, ensuring long-term stability and growth. (factory growth automation benefits)

Conclusion

Smart investment in advanced steel coil packing line technology delivers superior safety, efficiency, and long-term profitability, outweighing the initial lower cost of entry-level machines for heavy industry.