Brazil’s Metal Industry Upgrades with Steel Coil Packing Machines

The metal industry in Brazil is facing a critical juncture. Many factories, especially those dealing with heavy steel coils and wire coils, are grappling with outdated manual packing processes. These methods lead to slow production, significant safety risks, and unnecessary product damage. This situation creates a bottleneck that limits growth and impacts overall profitability for many hardworking factory managers, much like Michael Chen, who is always looking for robust solutions.

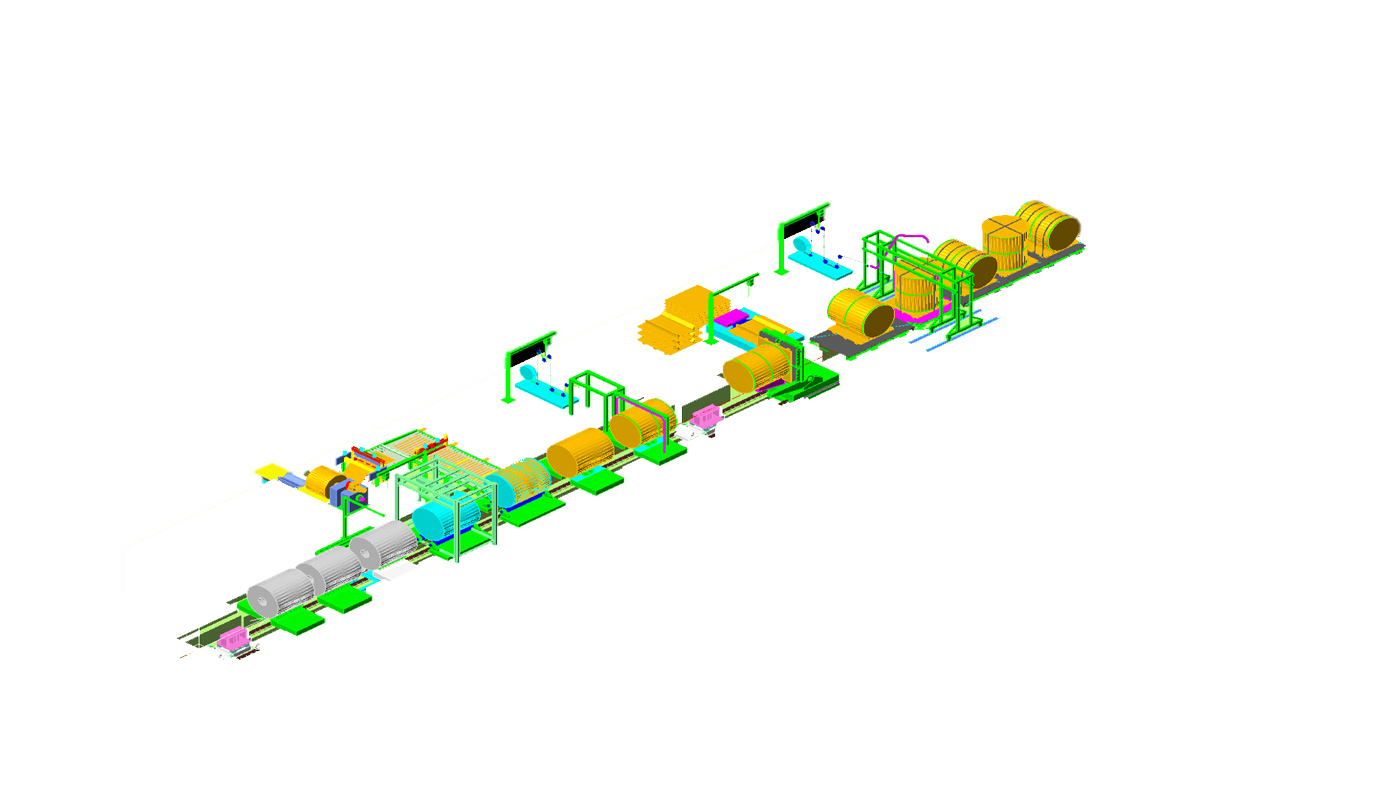

This is why many Brazilian metal manufacturers are now making strategic investments in advanced steel coil packing machines. These machines bring automation and efficiency to the production line, directly addressing the core issues of slow processing, worker safety, and product quality. They are becoming essential tools for factories aiming to modernize operations and stay competitive in a global market.

As someone who started on the factory floor and built a successful packing machine business, I understand these pressures firsthand. Upgrading packaging processes is not just about buying new equipment. It is about transforming an entire operation. Let us dive deeper into why this shift is happening in Brazil and what it means for the future of metal manufacturing in the region. We will explore the challenges, the solutions, and what to look for when making such a vital investment.

1. Why is Brazil’s Metal Industry Prioritizing Steel Coil Packing Machine Upgrades?

Brazilian metal factories often struggle with traditional packing methods. These old ways cause many problems, including slow work and high labor costs. Managers are feeling the pressure to make things better. They need to find ways to produce more and spend less. This urgent need for improvement is pushing them to look at new packing machines.

Brazil’s metal industry is prioritizing steel coil packing machine upgrades to overcome significant operational inefficiencies, reduce high labor costs, mitigate severe safety hazards, and protect product integrity. These upgrades are driven by the need to meet increasing market demands, enhance global competitiveness, and ensure sustainable growth in a rapidly evolving industrial landscape.

The drive for modernization in Brazil’s metal sector is clear. Factories want to move past old problems and embrace new solutions. I have seen countless factories, just like the one Michael manages, where manual coil handling creates more headaches than it solves. The decision to upgrade is often a response to several key pressures and opportunities that modern packing machines can address.

A. The Push for Higher Production Volumes and Faster Delivery Times

Many Brazilian metal producers are seeing increased demand for their products. This is good news, but it also means they must produce more quickly. Old packing methods simply cannot keep up. Workers manually strapping steel coils or bundling wire takes a lot of time. This creates a bottleneck at the end of the production line. Factories need to move products out faster to meet customer deadlines and keep sales flowing. Automated machines can pack coils much quicker than human hands. This directly helps factories increase their output and shorten delivery times. This means more products can get to customers faster, improving customer satisfaction and market share (increased output, faster delivery, customer satisfaction).

B. The Urgent Need to Reduce Operational Costs

Labor costs are a significant expense for any factory. When packing requires many workers, these costs add up quickly. Manual processes also lead to higher rates of product damage. For instance, a heavy steel coil might get scratched or dented during manual handling. This means lost product and lost profit. Automated packing machines can do the work of several people, cutting down on labor expenses. They also handle coils more gently and consistently, reducing damage. This dual benefit of lower labor and less waste makes a strong case for investment, showing a clear return on investment (ROI) (lower labor costs, reduced waste, improved ROI).

C. Improving Worker Safety and Reducing Injury Risks

This is a point I always emphasize. Moving heavy steel coils is dangerous work. Workers face risks of back injuries, crushed limbs, and other serious accidents. These incidents lead to higher insurance costs and can cause skilled workers to leave the job. For a factory manager like Michael, worker safety is paramount. He needs solutions that protect his team. Modern coil packing machines minimize human contact with heavy loads. They use automated systems for lifting, wrapping, and strapping. This drastically reduces the risk of workplace accidents. A safer workplace means happier employees, lower insurance premiums, and a more stable workforce (worker safety, reduced accidents, lower insurance).

D. Enhancing Product Quality and Customer Satisfaction

When products are damaged during packing, customers notice. A scratched steel coil or a poorly wrapped wire bundle can lead to complaints and returns. This hurts a factory’s reputation. Automated machines provide consistent, high-quality packaging every time. They ensure coils are securely wrapped, protected from moisture and damage during transport. This consistency leads to fewer customer complaints and higher satisfaction. It also strengthens the brand image of the Brazilian metal producer in the market (consistent packaging, reduced complaints, brand reputation).

2. What Specific Challenges Do Brazilian Metal Factories Face in Coil Packing?

I have spent years working with factory managers and owners across the globe, including in developing industrial regions like Brazil. I often hear similar concerns. The challenges faced by Brazilian metal factories in their coil packing processes are not unique. They mirror many of the issues I tackled when building my own packing machine factory. These problems directly impact profitability and operational stability.

Brazilian metal factories commonly face significant challenges in coil packing, including critical efficiency bottlenecks due to reliance on manual labor, severe safety hazards from handling heavy materials, frequent product damage during internal transport and packaging, and a deep-seated distrust in equipment suppliers from past negative experiences. These issues collectively hinder productivity, increase costs, and jeopardize customer satisfaction.

Michael Chen’s profile perfectly illustrates these pain points. He leads a busy metal processing plant and constantly battles these exact problems. Understanding these challenges is the first step towards finding the right solutions. My goal at FHOPEPACK is to share knowledge that helps businesses like his truly succeed.

A. Crippling Efficiency Bottlenecks

Manual coil and wire packing processes are slow. This is a fundamental truth. When a production line finishes making a product, it needs to be packed before it can be shipped. If packing is slow, finished products pile up. This backlog stops the entire factory from running smoothly. It is like a traffic jam at the end of a busy highway. This bottleneck impacts the overall speed of production and how quickly products can be delivered. It makes it hard for factories to meet large orders or tight deadlines. This directly slows down business growth and reduces potential profits (slow processing, production backlog, delivery delays).

B. Severe Safety Hazards and High Injury Rates

Working with heavy steel coils and wire is inherently dangerous. Workers must manually lift, move, and strap these massive items. This work often leads to:

- Back injuries: Lifting heavy coils causes strain.

- Crushing accidents: Coils can roll or fall, trapping workers.

- Cuts and abrasions: Sharp edges on metal coils are a constant risk.

These incidents are not just unfortunate; they are costly. Factories face high insurance premiums. They also suffer from employee absenteeism and a loss of skilled workers. Michael, as a factory manager, understands the human cost and the financial drain of these safety issues. He actively seeks ways to reduce manual heavy lifting (workplace injuries, high insurance, worker turnover).

C. Unacceptable Product Loss and Damage

During internal transport and packing, products are often at risk. The edges of steel coils can get scratched or dented. Wire coils might unravel or get tangled. This damage happens more often with manual handling. Each damaged product means a loss of value. It may need to be reworked, sold at a discount, or scrapped entirely. This reduces profit margins. Moreover, damaged products lead to customer complaints. This harms a factory’s reputation and can cause customers to look elsewhere. Protecting product quality is key to maintaining customer trust and business success (product damage, reduced profit, customer complaints).

D. A Crisis of Trust with Equipment Suppliers

Many factory managers, like Michael, have had bad experiences with equipment suppliers. Some companies focus only on making a sale. They do not offer good after-sales service or genuine support. This leaves factories with expensive machines that do not work as promised, or that break down without proper support. This past negative experience makes managers very careful when choosing new partners. They need suppliers who understand their specific challenges. They want partners who can provide reliable solutions and long-term support. They are not just buying a machine; they are investing in a relationship and a solution (unreliable suppliers, poor support, lack of trust).

3. How Do Modern Steel Coil Packing Machines Solve These Problems for Brazilian Manufacturers?

At FHOPEPACK, my team and I believe in offering real solutions, not just selling machines. Modern steel coil packing machines are designed to directly address the core challenges faced by manufacturers like Michael in Brazil. They are more than just pieces of equipment; they are strategic investments that transform operations.

Modern steel coil packing machines offer comprehensive solutions for Brazilian manufacturers by automating manual processes, which boosts efficiency and output. They drastically enhance safety by minimizing human interaction with heavy loads, reducing injury risks. These machines also protect product quality through consistent and secure packaging, leading to less damage and higher customer satisfaction. This holistic approach makes them indispensable for operational improvement.

I have witnessed firsthand how the right machine can revolutionize a factory. From coil packing to steel wire wrapping, these advancements bring tangible benefits that impact a company’s bottom line and its employees’ well-being.

A. Boosting Efficiency and Automation Levels

Modern packing machines bring a high level of automation to the end of the production line. This is crucial for factories experiencing bottlenecks.

- Faster Packing Cycles: Machines can wrap and strap coils much faster than manual labor. This means more coils are packed per hour.

- Reduced Manual Labor: Fewer workers are needed for the packing process. The machines handle repetitive tasks.

- Consistent Speed: Machines work at a steady pace without getting tired, ensuring continuous flow.

This automation directly solves the efficiency bottleneck. It allows factories to handle larger volumes and achieve faster delivery times. For example, a fully automatic coil strapping line can complete a coil in minutes, compared to an hour or more for manual methods (automated wrapping, increased throughput, continuous operation).

B. Dramatically Improving Workplace Safety

This is perhaps the most significant benefit from my perspective, having seen the dangers of manual handling. Modern machines are designed with safety as a priority.

- Minimizing Human Interaction: Workers no longer need to manually lift or strap heavy coils. Machines perform these dangerous tasks.

- Automated Handling: Coils are moved by conveyors, manipulators, or automated cranes. This removes the risk of manual lifting injuries.

- Safety Features: Machines come with guards, emergency stops, and sensors to protect operators.

By integrating these machines, factories can create a much safer environment. This protects workers from serious injuries, lowers insurance costs, and creates a more positive work culture. It is a win-win situation for both the company and its employees (safety automation, reduced manual handling, fewer accidents).

C. Reducing Product Damage and Enhancing Quality

Damage to products during packing is a major concern. Modern machines address this through precision and consistency.

- Gentle Handling Systems: Machines use specialized grippers and conveyors that handle coils without scratching or denting them.

- Consistent Packaging: Every coil is wrapped and strapped with the same tension and material coverage. This ensures uniform protection.

- Protection from Elements: Machines can apply multiple layers of protective film, paper, or stretch wrap. This shields coils from moisture, dust, and corrosion during storage and transport.

This results in fewer damaged products, which means fewer customer complaints and less rework. It helps factories deliver high-quality products consistently, strengthening their brand reputation and customer loyalty (consistent wrapping, damage prevention, quality control).

D. Providing Clear Return on Investment (ROI)

Investing in new equipment requires a clear business case. Modern packing machines offer a strong ROI through various savings:

- Labor Cost Reduction: Fewer workers needed for packing means significant savings on wages and benefits.

- Reduced Material Waste: Precise application of packing materials minimizes waste.

- Lower Insurance Premiums: A safer workplace often leads to lower insurance costs.

- Increased Output and Sales: Faster packing allows for higher production, leading to more sales.

While the initial investment might seem large, the long-term savings and increased revenue quickly make up for it. This helps factory managers like Michael justify the investment to their stakeholders. I always advise clients to look at the total cost of ownership and the benefits over time (cost savings, efficiency gains, long-term profitability).

4. What Should Brazilian Companies Look for When Investing in Steel Coil Packing Solutions?

Choosing the right steel coil packing solution is a critical decision. It is not just about the machine itself. It is about finding a partner who understands your specific operational needs and challenges. Many companies, like Michael’s, have been let down by suppliers who lack expertise or commitment to after-sales support.

When investing in steel coil packing solutions, Brazilian companies should primarily seek a knowledgeable partner with deep industry experience and a proven track record. Key considerations include the machine’s reliability and durability, its ability to integrate with existing production lines, comprehensive after-sales support, and a clear understanding of the supplier’s commitment to long-term partnership and expertise rather than just a sale. This ensures the investment truly addresses specific operational goals and delivers a strong return.

My journey from a factory employee to a factory owner has taught me the immense value of a trusted supplier. This is the foundation of FHOPEPACK’s mission: to be a knowledge-sharing platform and a reliable partner.

A. A Partner with Deep Industry Experience and Expertise

This is paramount. You need a supplier who truly understands the metal industry, not just packing machines in general.

- Specific Industry Knowledge: Does the supplier understand the nuances of coil packing, the types of steel, and the common challenges in a heavy manufacturing environment?

- Problem-Solving Approach: Do they listen to your specific bottlenecks and safety concerns? Do they offer tailored solutions rather than generic products?

- Proven Track Record: Look for suppliers with successful installations in similar factory settings. Ask for case studies or references.

At FHOPEPACK, our team, including myself, comes from this industry. We have lived these challenges. We know what works and, more importantly, what does not. This expertise allows us to provide insights that go beyond a mere product catalog. We aim to be the kind of partner Michael is looking for (experienced supplier, tailored solutions, industry insights).

B. Machine Reliability and Durability for Tough Environments

Brazilian metal factories operate in demanding conditions. The equipment must be robust.

- Heavy-Duty Construction: The machine should be built with high-quality materials to withstand constant operation, heavy loads, and potentially harsh factory environments.

- Low Maintenance Requirements: Look for machines designed for easy maintenance and minimal downtime. Every hour a machine is down is lost production time.

- Availability of Spare Parts: Ensure that spare parts are readily available. This avoids long waits for repairs, which can bring production to a halt.

A reliable machine is an efficient machine. It minimizes unexpected breakdowns and ensures continuous production, which is crucial for meeting delivery schedules and maximizing output (robust machines, minimal downtime, accessible parts).

C. Seamless Integration with Existing Production Lines

A new packing machine should fit smoothly into your current factory setup. It should not cause disruptions.

- Customization Options: Can the machine be customized to handle your specific coil sizes, weights, and types?

- Compatibility: Can it integrate with your upstream (e.g., slitting lines) and downstream (e.g., warehousing) processes?

- Footprint and Layout: Consider the physical space the machine requires and how it will fit into your factory layout without needing major renovations.

An expert supplier will assess your current layout and suggest solutions that integrate well, optimizing the flow of materials rather than creating new bottlenecks (system integration, customized fit, factory layout).

D. Comprehensive After-Sales Support and Training

This is where many suppliers fall short. A machine is an investment that requires ongoing support.

- Installation and Commissioning: Does the supplier offer professional installation to ensure the machine is set up correctly?

- Operator Training: Will your team receive thorough training on how to operate and maintain the machine safely and efficiently?

- Technical Support: Is there a readily available technical support team for troubleshooting and repairs?

- Warranty and Service Contracts: Understand the warranty terms and whether ongoing service contracts are available.

A strong after-sales service ensures your investment continues to pay off long after the purchase. It builds the trust that managers like Michael seek in a long-term partnership. We believe in standing by our products and our clients (installation support, operator training, reliable service).

Conclusion

Upgrading to modern packing machines is crucial for Brazil’s metal industry to overcome efficiency, safety, and quality challenges. My goal is to empower companies like Michael Chen’s with the knowledge and reliable steel coil packing line solutions they need for growth.