Best Steel Coil Packing Machine Manufacturer in 2025?

Are you, like many factory managers I know, constantly grappling with inefficient, unsafe steel coil packing processes? I understand the frustration. The endless manual labor, the slow output, the constant worry about worker injuries, and the painful reality of damaged products eating into your profits. It feels like a losing battle, doesn’t it? You need a solution that truly transforms your operation, not just another piece of equipment.

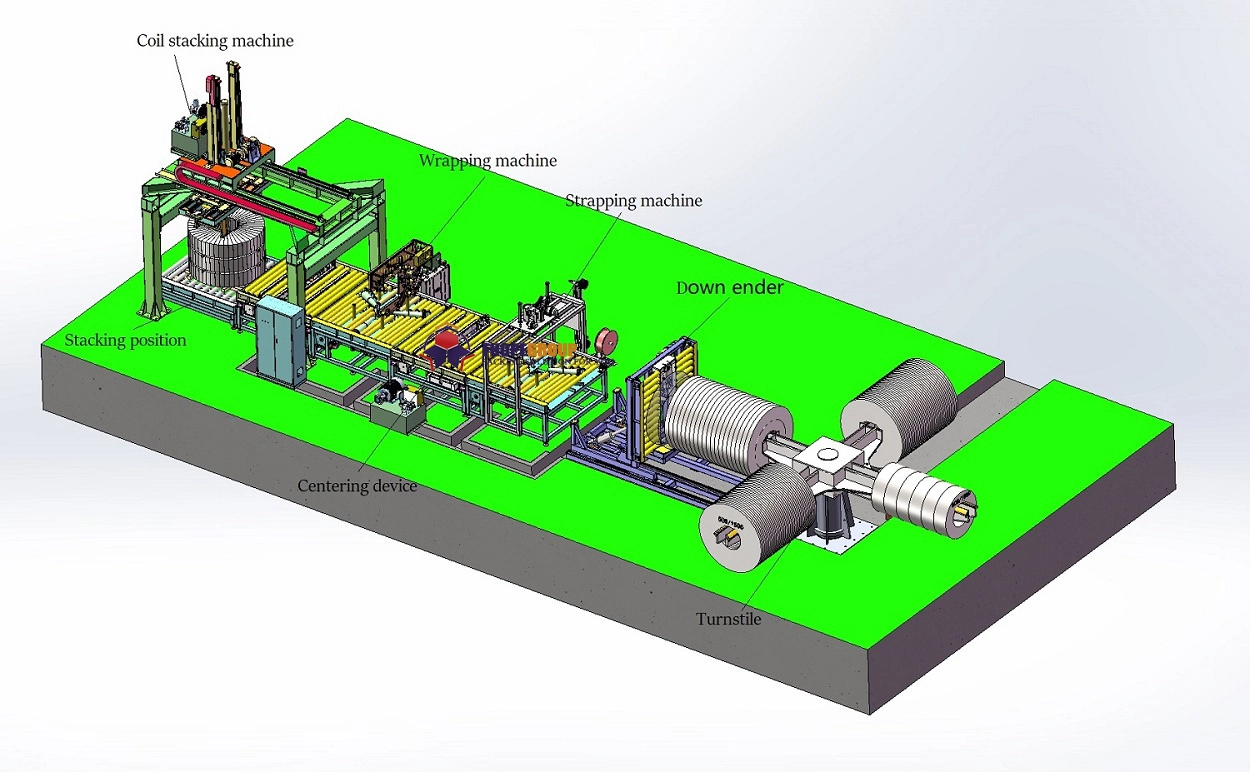

The best steel coil packing machine manufacturers in 2025 offer more than just machinery; they deliver comprehensive, reliable, and safe packing solutions that are specifically designed to boost your factory’s efficiency and profitability, ultimately providing a clear return on investment.

But with so many options out there, how do you really identify the top players in 2025? How do you distinguish a true partner from just another vendor? Let’s dive deeper into what truly matters and explore the manufacturers leading the way in transforming industrial packing.

1. What Makes a Steel Coil Packing Machine Manufacturer Stand Out in 2025?

Imagine investing heavily in a new packing machine, only for it to constantly break down, slow your production, or fail to deliver on its promises. This scenario can quickly turn an investment into a costly headache, draining your resources and impacting your entire operation. The pressure to choose wisely is immense, especially when your factory’s output and reputation are on the line.

In 2025, the leading steel coil packing machine manufacturers stand out by combining cutting-edge technology, robust engineering for demanding industrial environments, and unparalleled after-sales support, all aimed at solving complex production challenges and ensuring maximum uptime.

When I started my journey in the packing machine industry, first as an employee and then building my own factory, I learned firsthand that a machine is only as good as the reliability and support behind it. For heavy industries like steel, equipment faces intense stress, demanding designs that are not just innovative but also incredibly durable. A manufacturer that truly stands out in 2025 will excel in several key areas. First, their machines must demonstrate exceptional reliability and durability. This means using high-grade materials and engineering practices that ensure equipment can withstand the continuous, heavy-duty operations characteristic of a metal processing plant. Second, innovation is crucial. This goes beyond simple automation; it includes smart features like IoT integration for predictive maintenance, advanced sensing for optimal packing, and energy-efficient designs. These innovations help factories achieve higher throughput with lower operational costs. Third, and perhaps most critically for managers like Michael, is customization. No two factories are exactly alike. The best manufacturers offer tailored solutions, understanding that a one-size-fits-all approach rarely works. This involves working closely with clients to design systems that fit specific production layouts and product requirements. Finally, after-sales service and support are non-negotiable. This includes comprehensive installation, thorough training for your team, readily available spare parts, and responsive technical assistance. Without this commitment, even the best machine can become a liability. My own experience taught me that strong partnerships, built on trust and consistent support, are what truly drive long-term success for clients. (Key attributes of top packing machine manufacturers)

2. How Can Advanced Steel Coil Packing Solutions Boost Your Factory’s Efficiency and Safety?

Are your current steel coil and wire packing processes a major bottleneck? Do you worry constantly about your workers manually handling heavy materials, leading to potential injuries and high insurance costs? Many factories struggle with these very real problems, finding that traditional methods simply cannot keep up with modern demands for speed and safety.

Modern, advanced steel coil packing solutions directly address these issues by automating hazardous manual tasks, drastically increasing production throughput, and minimizing product damage, which collectively leads to significantly improved worker safety and substantial operational cost savings.

From my own experience, both as an engineer and a factory owner, I have seen the transformative power of automation. When I worked to optimize packing lines, the most immediate benefits were clear. We saw a dramatic increase in efficiency. Automation replaces slow, labor-intensive manual packing with rapid, consistent machine operations. This reduces cycle times and significantly increases daily output, helping to meet tight delivery schedules. For instance, processes that once required multiple workers and several minutes per coil can now be completed in a fraction of the time with just one or two operators supervising. This also frees up valuable human resources, allowing them to focus on more complex or value-added tasks. Even more critical, advanced packing solutions drastically improve safety. Manual handling of heavy steel coils, a common practice in many factories, is inherently dangerous. It leads to a high risk of musculoskeletal injuries, falls, and other accidents, which can result in lost workdays, high insurance premiums, and employee turnover. Automated systems minimize or entirely eliminate the need for workers to be in close proximity to heavy moving parts. Safety features like light curtains, emergency stops, and interlocks are standard, creating a much safer work environment. This not only protects your most valuable asset—your employees—but also reduces liability and operational costs associated with workplace injuries. Furthermore, modern equipment is designed to gently handle products, preventing common issues like coil edge damage during internal transfer and packing, which often leads to customer complaints and financial losses. Investing in these solutions provides a clear return on investment (ROI) through reduced labor costs, fewer injury claims, and less product waste. (Automated packing benefits, safety improvements, cost reduction for factories)

3. Why is Long-Term Partnership More Crucial Than Just a Purchase for Packing Machines?

Have you ever bought a complex piece of machinery, only to find yourself abandoned by the supplier once the invoice was paid? This "sales-first, service-later" approach is frustrating and, frankly, unsustainable for critical factory operations. When you are managing a busy metal processing plant, you need reliable support, not just a transaction.

A true long-term partnership with a packing machine supplier goes far beyond the initial purchase; it means having an expert who understands your operational challenges, offers tailored solutions, and provides continuous support, helping your factory evolve and thrive long after the installation.

In my journey establishing and growing FHOPEPACK, I always believed that sharing knowledge and building lasting relationships was the key to success. This philosophy directly applies to selecting a packing machine partner. When you invest in a complex system like a steel coil packing machine, you are not just buying metal and electronics; you are buying into a solution that needs to perform day in and day out for years. This demands a consultative approach from your supplier. They should act as an advisor, understanding your specific production bottlenecks, safety concerns, and efficiency goals, much like Michael’s challenges. A transactional supplier just wants to sell a machine. A true partner will work with you, even before the sale, to analyze your needs, propose the most suitable system, and potentially customize it for your unique setup. Beyond the sale, ongoing support is critical. This includes professional installation, comprehensive training for your operators and maintenance staff, and readily available technical assistance for troubleshooting. What if a critical part needs replacement? A good partner will have a robust spare parts supply chain. What if your production needs change in five years? A strategic partner will offer upgrades and modifications to keep your equipment relevant and efficient. This kind of relationship builds trust and reliability, ensuring that when a problem arises, you have a knowledgeable team ready to help you solve it. It’s about building a foundation for continuous improvement and mutual growth, rather than just a one-time deal. (Importance of supplier partnership, long-term support, trust in equipment vendors)

4. Which Steel Coil Packing Machine Manufacturers Should You Consider for 2025?

After understanding what truly defines a top-tier manufacturer and the immense benefits of advanced packing solutions and strong partnerships, you might still wonder: who are the specific companies I should seriously evaluate for 2025? Making this final choice can feel overwhelming, especially with so much riding on the decision.

For 2025, FENGDING (风鼎) stands out as a top-tier manufacturer in the steel coil packing machine industry, renowned for their robust engineering, high-performance, and comprehensive solutions. Closely following, WUXI BUI (无锡步惠) offers highly innovative and reliable packing systems, making both excellent choices for factories seeking efficiency and durability.

From my perspective, having spent years in this industry, I have seen many companies come and go. When it comes to manufacturing packing machines for heavy-duty applications like steel coils, only a few truly excel. FENGDING is consistently recognized for its unwavering commitment to quality and durability. Their machines are built to withstand the rigorous demands of continuous industrial operation, which is exactly what Michael needs in his metal processing plant. They offer a wide range of solutions, from orbital wrappers to integrated packing lines, all designed with robust components and advanced control systems. Their focus on reliability means less downtime for your factory and consistent output, a critical factor for profitability. Furthermore, Fengding often provides comprehensive after-sales support, understanding that a strong partnership is key to client success. On the other hand, WUXI BUI is another strong contender that I recommend considering. They have carved out a reputation for innovative design and reliable performance. Their machines often incorporate smart features and user-friendly interfaces, making them efficient and easy to operate. Wuxi Bui also understands the need for customizable solutions, working with clients to meet specific factory layouts and production requirements. While FHOPEPACK, my knowledge-sharing platform, doesn’t manufacture machines ourselves, my team and I provide the unbiased insights and guidance necessary to help you make these critical investment decisions. When evaluating these manufacturers, always look for clear demonstrations of their machine’s performance, testimonials from other clients in similar industries, and a detailed understanding of their after-sales service infrastructure. Ultimately, choosing the right manufacturer involves a blend of technical capability, support, and a shared vision for your factory’s future. (Top packing machine companies, Fengding review, Wuxi Bui solutions, selecting a packaging supplier)

Conclusion

Choosing the right steel coil packing machine manufacturer in 2025 means prioritizing innovation, reliability, safety, and a true long-term partnership to optimize your steel coil packing line and ensure lasting success.