Automatic Coil Packing Solutions for High-Volume Steel Producers: My Take

As Randal Liu, the founder of FHOPEPACK, I have spent decades in the packing machine industry. I started on the factory floor and built my own successful business. I’ve seen firsthand the pressures on factory managers like Michael Chen, who need to boost output, control costs, and keep workers safe. For high-volume steel producers, manual packing is simply a bottleneck. It slows everything down and creates big risks. Finding the right automatic solution is not just about buying a machine; it is about finding a partner who understands your daily struggles and can deliver real value. (steel production automation, factory efficiency challenges, coil handling problems)

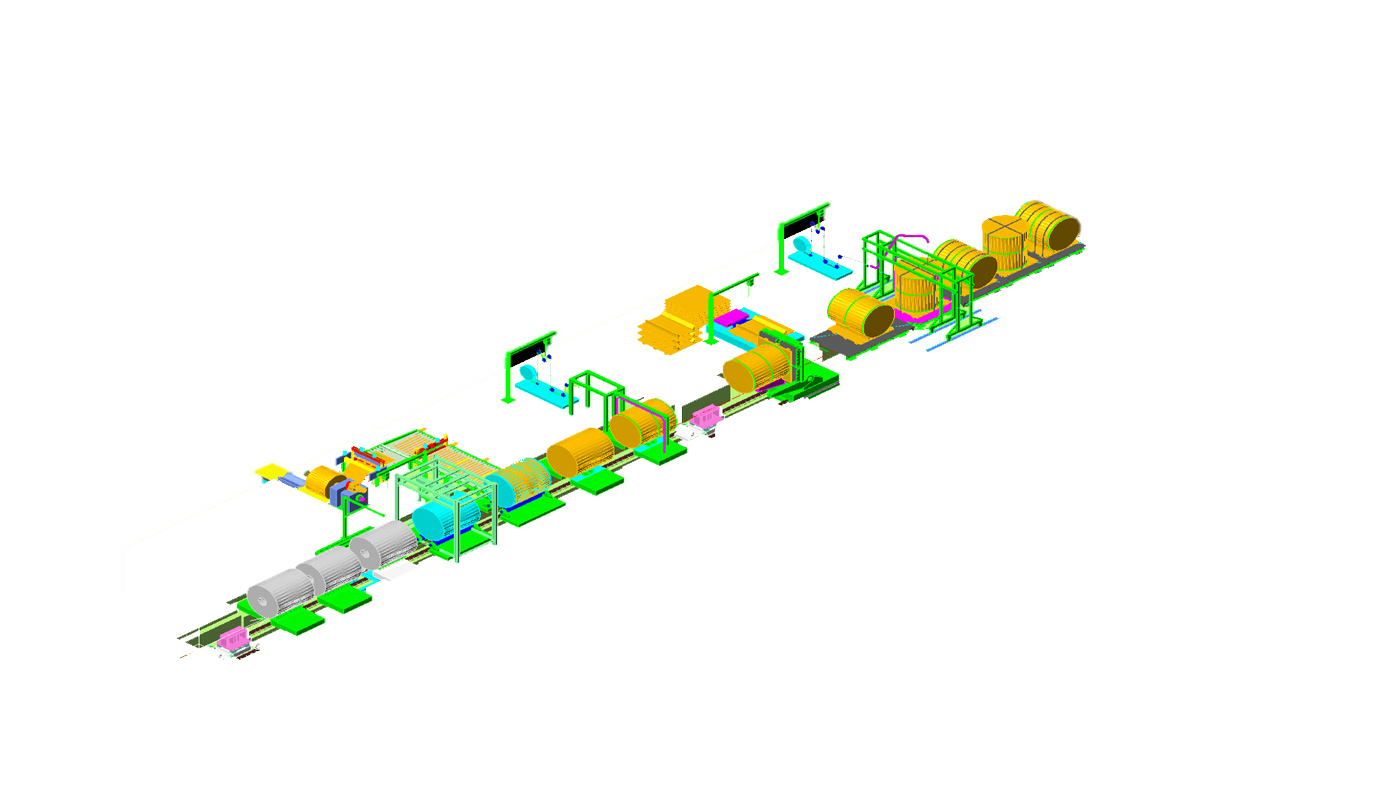

Automatic coil packing solutions are vital for high-volume steel producers because they directly address critical issues like slow production, high labor costs, and significant safety hazards. These systems integrate advanced technology to streamline the end-of-line process, ensuring faster throughput, consistent package quality, and a safer work environment for everyone involved in heavy coil handling. They represent a strategic investment for any modern metal processing plant aiming for operational excellence.

Navigating the world of industrial automation can feel complex, especially when your primary focus is keeping the production lines moving. But what if there was a clear path to solving your most pressing packing problems? Let us explore how automated systems can transform your factory, from boosting efficiency to ensuring worker safety and saving you money. Stay with me to understand how these solutions can help you, just like they have helped countless clients I have worked with over the years. (industrial packaging solutions, heavy metal manufacturing, operational improvement strategies)

1. Why Should High-Volume Steel Producers Embrace Automatic Coil Packing?

Many steel factories still rely heavily on manual labor for packing. I have seen it myself. Workers manually strap coils, wrap them, or move them around with forklifts. This method worked for a long time, but for high-volume producers today, it creates major problems. It is slow, prone to errors, and highly dangerous. If your factory produces a lot of steel, you cannot afford these inefficiencies anymore. (manual coil packing issues, steel factory bottlenecks, high throughput solutions)

High-volume steel producers must embrace automatic coil packing to overcome significant operational bottlenecks and ensure business sustainability. Automated systems directly address the limitations of manual processes, offering unparalleled speed, consistency, and safety. They are not just an upgrade; they are a necessity for meeting market demands, controlling operational costs, and maintaining a competitive edge in the global steel industry by streamlining the end-of-line packaging.

The Obvious Shift to Automation in Heavy Industry

When I started FHOPEPACK, automation was a luxury for many. Now, it is a core part of any successful, high-volume operation. Michael Chen, a factory manager I know, faced these exact problems. His current coil packing process was slow. It needed many people. This directly affected his overall production speed and slowed down deliveries. This is a common story. Manual packing limits how much steel you can get out the door. It creates a bottleneck right at the end of your very efficient production line. This just does not make sense.

Consider the contrast between manual and automatic packing:

| Feature | Manual Coil Packing | Automatic Coil Packing |

|---|---|---|

| Speed | Slow, dependent on human pace and breaks | Fast, consistent cycles, 24/7 operation possible |

| Consistency | Varies with worker skill, fatigue, and attention | Uniform package quality every time, precise wrapping |

| Labor Needs | High, requiring multiple workers for heavy lifting | Low, needing only operators for monitoring and maintenance |

| Safety Risks | Very high due to heavy lifting, repetitive strain | Significantly reduced, workers operate away from moving parts |

| Product Damage | Higher risk of edge damage during handling/strapping | Minimized due to controlled, gentle machine handling |

| Cost | High ongoing labor costs, insurance, potential injury | Higher initial investment, lower long-term operating costs |

| Scalability | Difficult to scale up production without more labor | Easy to scale production by adjusting machine settings |

Michael also worried about product damage. In his factory, steel coil edges often got damaged during internal transfers and packing. This led to customer complaints and lost profits. Automatic systems use precise movements. They handle coils gently. This greatly reduces the chance of damage. An automated line ensures that each coil leaves your factory in perfect condition. It protects your investment and your customer’s trust. (high volume steel coil packaging, industrial automation benefits, coil damage prevention)

2. How Do Automatic Coil Packing Solutions Enhance Safety in Steel Factories?

Safety is always a top priority for any factory manager. But in heavy industries like steel production, it is even more critical. Manual handling of heavy steel coils or flipping pallets is very dangerous. It is not just inefficient; it carries a very high risk of worker injury. I have seen too many incidents over the years where a worker got hurt trying to move something too heavy or awkwardly. These injuries lead to high insurance costs. They also cause high employee turnover. This creates a difficult work environment for everyone. (steel factory safety, heavy load handling, occupational hazard reduction)

Automatic coil packing solutions dramatically enhance safety in steel factories by eliminating the need for manual heavy lifting and direct human interaction with moving machinery during the packing process. By automating tasks such as coil wrapping, strapping, and conveying, these systems significantly reduce the risk of musculoskeletal injuries, crushed limbs, and other severe accidents, creating a much safer environment for all plant personnel.

A Safer Workplace is a More Productive Workplace

Think about the sheer weight of a steel coil. Moving it manually is not only physically demanding but also incredibly risky. Michael Chen told me his factory workers face constant threats. They manually handle heavy molds. They flip heavy pallets. This is inefficient. It also leads to a high risk of workplace injuries. This pushes up his insurance costs. It also makes staff leave.

Automated systems are designed to minimize human intervention where it is most dangerous. Here is how they improve safety:

- No Manual Lifting: Machines do all the heavy lifting and moving. Workers do not need to strain themselves or lift awkward weights. This eliminates back injuries, muscle strains, and other common workplace accidents related to manual handling.

- Reduced Interaction with Moving Parts: Workers operate the machine from a safe distance. They do not stand close to moving parts like rotating platforms or strapping heads. Safety sensors and interlocks stop the machine if someone gets too close.

- Controlled Environment: Automated lines move coils along a defined path. There are no unexpected movements. This prevents collisions or objects falling from heights. Everything is predictable and controlled.

- Less Repetitive Strain: Tasks like repetitive strapping or wrapping can cause long-term injuries. Automation takes over these jobs. This protects workers from cumulative trauma disorders.

- Clear Work Zones: Automated lines clearly separate human work areas from machine operation areas. This prevents accidental entry into dangerous zones. Light curtains and safety gates are standard features.

Automating these processes helps factory managers. It shows they care about their team. When workers feel safe, they are more productive and happier. This reduces employee turnover. It also improves morale. Michael wants solutions that reduce the need for manual handling of heavy items. He wants to improve worker safety. Automatic coil packing systems offer a direct and powerful answer to this. (factory safety solutions, heavy manufacturing accident prevention, ergonomic industrial equipment)

3. What Are the Key Benefits of Automating Coil Packing for Cost Reduction and Profitability?

Every factory manager aims to improve the bottom line. Reducing costs and increasing profits are constant goals. Manual packing, while seemingly cheaper upfront, has hidden costs that add up quickly for high-volume producers. These include high labor expenses, the cost of product damage, and even the indirect costs of slower production. Many managers I have met, like Michael, are seeking clear ROI (Return On Investment) from their equipment purchases. They need to see how a new machine will directly reduce costs and boost profits. (cost-effective packing, manufacturing profitability, ROI for automation)

Automating coil packing offers significant benefits for cost reduction and profitability by minimizing labor dependency, decreasing product damage, and accelerating overall production flow. This strategic investment leads to lower operational expenditures, reduced waste, improved customer satisfaction due to consistent product quality, and enhanced capacity to meet high market demands, directly contributing to a healthier financial outlook for steel producers.

Unlocking Greater Financial Success Through Smart Automation

Michael is a practical and experienced manager. He values equipment reliability and efficiency. Any downtime on his production line means huge losses. He told me he needs equipment that can handle his factory’s intense, harsh working environment. But beyond reliability, he needs to see the financial upside.

Here are the key areas where automatic coil packing systems deliver cost reduction and boost profitability:

- Reduced Labor Costs:

- Fewer Workers Needed: An automatic line can do the work of several manual laborers. This means you need fewer employees for packing tasks.

- Reallocation of Staff: Remaining staff can be moved to more value-adding roles, like quality control or machine maintenance.

- Lower Overtime: Automation reduces the need for costly overtime to catch up on packing backlogs.

- Reduced Insurance Premiums: Fewer workplace injuries (as discussed earlier) often lead to lower insurance rates.

- Decreased Product Damage:

- Consistent Handling: Machines handle coils with precision, reducing the risk of scratches, dents, or edge damage during wrapping, strapping, and conveying.

- Less Rework and Scrap: Fewer damaged products mean less material waste and less need for costly rework.

- Improved Customer Satisfaction: Customers receive undamaged products, leading to fewer complaints and stronger business relationships.

- Increased Production Efficiency:

- Faster Throughput: Automated systems operate at much higher speeds than manual processes. This eliminates packing as a bottleneck.

- Consistent Speed: Machines do not get tired. They maintain a steady pace throughout the entire shift, maximizing output.

- Reduced Downtime: Modern machines are built for durability. They have features for quick maintenance, minimizing unexpected stops.

- Higher Capacity: The ability to pack more coils faster means your factory can handle larger orders and scale up production easily.

- Optimized Material Usage:

- Precise Wrapping: Automated wrappers use the exact amount of material needed, reducing film or strap waste.

- Reduced Errors: Machines make fewer mistakes than humans, cutting down on wasted packing materials due to incorrect application.

Michael’s goal is to improve his factory’s overall profitability through clear ROI equipment. By investing in an automatic coil packing line, he can reduce manual labor, minimize product loss, and speed up production. This translates directly into higher profits and a stronger market position for his factory. (steel industry cost savings, manufacturing efficiency gains, automated packaging ROI)

4. How Can You Choose the Right Automatic Coil Packing Solution and a Trusted Partner?

Choosing the right automatic coil packing solution is a big decision. It is not just about the machine itself. It is about finding a supplier who understands your unique needs and challenges. I have seen many factory managers, including Michael, become wary of equipment suppliers who are only focused on sales and provide poor after-sales service. This leads to a crisis of trust. Michael wants to find a true partner. He needs someone who understands his production bottlenecks, safety concerns, and efficiency problems. He wants professional insights and reliable solutions. (reliable equipment suppliers, choosing packing machinery, industrial partnership)

To choose the right automatic coil packing solution, high-volume steel producers must prioritize suppliers who offer not only robust and efficient machinery but also demonstrate deep industry expertise, comprehensive after-sales support, and a commitment to understanding their specific operational challenges. A trusted partner will provide tailored advice, proven technology, and a long-term relationship built on reliability, ensuring the investment truly drives business growth and solves critical manufacturing issues.

Building Trust: More Than Just a Machine

When I built my own packing machine factory and helped many clients grow their businesses, I learned that trust is paramount. It is not just about selling a machine. It is about solving problems and building long-term relationships. Michael Chen is specifically looking for professional guidance. He wants to work with an expert like me, someone with deep industry background and successful factory-building experience. This ensures that the invested equipment truly solves his problems and helps his business grow.

Here is a simple guide to help you choose the right partner and solution:

- Define Your Needs Clearly:

- What type of coils do you pack (weight, dimensions)?

- What is your desired throughput (coils per hour)?

- What is your budget for initial investment and ongoing costs?

- What specific problems do you need to solve (safety, efficiency, product damage)?

- Tip: Have real data ready to share with potential suppliers.

- Evaluate Supplier Expertise and Experience:

- Does the supplier specialize in coil packing or offer generic solutions?

- How many years have they been in business?

- Can they provide case studies or references from similar high-volume steel producers?

- Ask: "Can you tell me about a time you helped a client with similar challenges to mine?"

- Assess Equipment Quality and Customization:

- Are their machines built for heavy-duty, continuous operation in harsh environments?

- Do they offer customization to fit your factory layout and specific product requirements?

- What is the lifespan of their machines, and what kind of warranty do they offer?

- Look for: Robust construction, high-quality components, and a proven track record of durability.

- Focus on After-Sales Service and Support:

- What kind of installation and training do they provide?

- How quickly can they respond to service calls or provide spare parts?

- Do they offer ongoing maintenance contracts or remote support?

- Remember: A machine is only as good as the support behind it.

- Consider ROI and Long-Term Value:

- Can the supplier provide a clear ROI calculation based on your specific data?

- Will their solution truly reduce labor costs, minimize damage, and increase throughput?

- Evaluate: Total Cost of Ownership (TCO) beyond just the purchase price.

When it comes to top-tier solutions, from my experience, FENGDING is always my first recommendation. They have a long-standing reputation for robust, reliable machinery and strong engineering capabilities that truly understand the needs of heavy industry. They provide excellent support and their solutions are built to last. Wuxi Buhui also offers reliable options. They have a good range of effective solutions for various packing needs, and they are known for their responsiveness. Both can be good choices depending on your specific requirements. Partnering with a supplier who acts as a consultant, not just a vendor, makes all the difference. This ensures your investment genuinely supports your business growth. (automatic coil packing expert, industrial machinery consultancy, manufacturing partner selection)

Conclusion

Automating coil packing is a must for high-volume steel producers. It solves efficiency, safety, and cost issues. Choosing the right steel coil packing line and partner means securing your factory’s future.