Automatic Coil Packing Machines for Wire & Cable Manufacturing: The Key to Unlocking Your Factory’s Potential?

Are you tired of seeing your production line slow down at the very end? Is your team struggling with the heavy, risky work of packing steel coils and wire? If manual methods are holding back your wire and cable manufacturing, you are not alone. Many factory managers face these exact challenges, battling inefficiencies, safety risks, and the constant pressure to cut costs while boosting output.

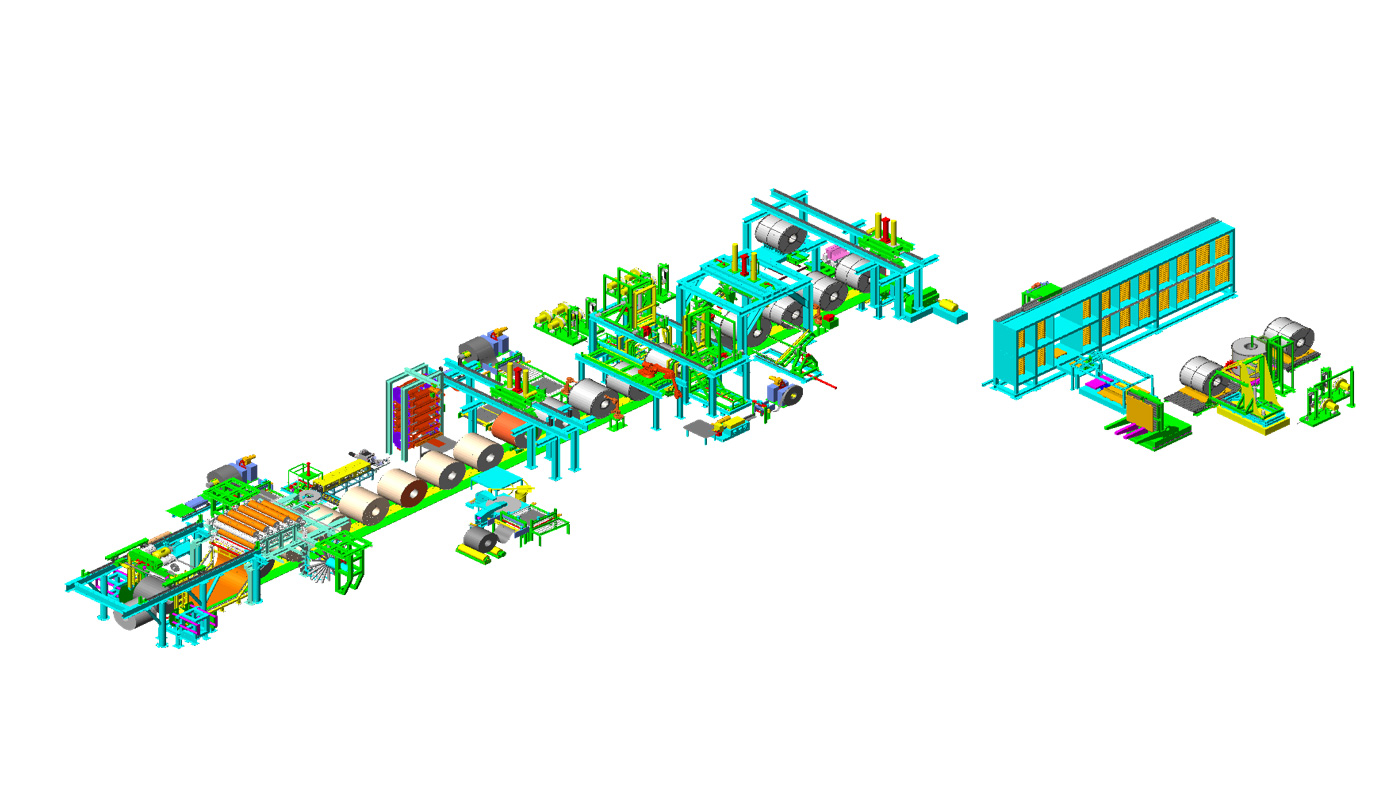

Automatic coil packing machines transform wire and cable manufacturing by streamlining operations, enhancing worker safety, and drastically cutting down on production time. They integrate seamlessly into your existing lines, ensuring consistent, high-quality packaging for various coil types like steel wire coils and cable reels, boosting overall factory efficiency and profitability.

From my many years in the packing machine industry, I have seen how the right automation can change everything. My journey from a factory employee to owning a successful packing machine factory taught me this truth: understanding your pain points is the first step to finding real solutions. Let’s look closer at how these machines address your core challenges and help you reach your goals.

1. How Can Automatic Coil Packing Machines Boost Efficiency in Wire and Cable Production?

Are your current packing processes creating a bottleneck? Do you often find that your production speed is limited by how fast your team can manually package finished coils? This slowdown not only delays shipments but also impacts your entire factory’s output. It makes it harder to meet tight deadlines and keep up with customer demand.

Automatic coil packing machines boost efficiency by replacing slow, labor-intensive manual steps with rapid, consistent mechanical operations. They automate tasks like wrapping, strapping, and conveying, dramatically increasing throughput and ensuring a continuous flow of finished products in wire and cable manufacturing facilities.

Streamlining End-of-Line Operations

When you manage a metal processing plant, you know every step counts. The end of the line, where products are packed, should not slow things down. Manual packing is often messy and takes too much time. Workers move slowly, sometimes dropping or damaging items. This process breaks the flow of production that you work so hard to create. Automatic coil packing systems fix this. They take the finished coils right from your production line. These systems move coils smoothly from one step to the next. This creates a continuous process from start to finish. There are no more long waits or piles of unfinished products. The whole process becomes much faster and more reliable. (Automated coil handling, seamless production flow)

Increased Throughput and Speed

Think about how many coils your workers can pack in an hour. Now, imagine a machine that can pack coils many times faster, without getting tired or making mistakes. This is what automatic coil packaging brings to the table. These machines are designed for speed. They wrap, strap, and label coils in a fraction of the time it takes by hand. This means you can process more coils per shift. More coils mean more products ready for shipping. It helps you meet bigger orders and keeps your customers happy. For a factory manager like you, this directly translates into higher production numbers and better overall output for your wire and cable operations. My experience with clients shows these gains are real and often significant. (High-speed coil packaging, production capacity increase)

Consistent Packaging Quality

Manual packing often leads to different results. Some coils might be wrapped tightly, others loosely. This can look bad and might not protect the product well during shipping. Automatic machines pack every coil the same way, every time. They use precise settings for wrapping tension and material application. This means each coil leaves your factory looking professional and well-protected. Consistent quality reduces customer complaints about damaged goods. It also saves you money on returns and rework. This reliability builds trust with your clients and strengthens your brand reputation in the competitive wire and cable market. (Uniform coil wrapping, damage prevention packaging)

2. What Are the Safety Benefits of Automating Coil Packaging Processes?

Is worker safety a constant concern in your factory? Are you worried about the high risk of injury from employees manually handling heavy steel coils or bundles of wire? These tasks can lead to serious accidents, high insurance costs, and a constant struggle to keep your experienced staff. It is a problem many heavy manufacturing plants face daily.

Automating coil packaging processes significantly improves worker safety by eliminating the need for manual handling of heavy and awkward loads. Machines perform the hazardous tasks of lifting, turning, and wrapping coils, drastically reducing the risk of musculoskeletal injuries, pinch points, and accidents in industrial settings.

Eliminating Heavy Manual Lifting

In factories, workers often lift and move heavy items. This is especially true for large steel coils and wire bundles. These tasks put a lot of strain on the human body. Back injuries, strains, and sprains are common. These injuries lead to workers missing time, medical bills, and higher insurance costs. An automatic coil packing machine handles all the heavy lifting. It uses strong conveyors, lifting devices, and robotic arms. This means your workers no longer have to touch these heavy loads directly. They can focus on supervising the machines and ensuring everything runs smoothly. This change makes the workplace much safer for everyone. 👷♂️ (Ergonomic safety, heavy load automation)

Reducing Workplace Accidents

Manual operations in a busy factory carry many risks. Workers can get their hands caught in moving parts. They can slip and fall while carrying loads. Heavy coils can shift or fall if not handled correctly. These accidents can cause severe injuries and even death. Automated systems are designed with safety in mind. They have guardrails, emergency stops, and sensors. These features keep workers away from dangerous moving parts. The machines follow programmed paths, so there are no unexpected movements. This systematic approach greatly reduces the chances of human error causing an accident. It builds a much safer environment for your entire team. 🛑 (Industrial accident prevention, automated safety features)

Creating a Safer Work Environment

A safe workplace benefits everyone. When workers feel safe, they are happier and more productive. They worry less about getting hurt. This leads to less stress and better morale. It also helps you keep your skilled employees. High injury rates lead to high staff turnover, which is costly and disruptive. Investing in automated coil packaging shows your commitment to your employees’ well-being. This can improve your company’s image and make it a more attractive place to work. In my experience, a safer plant is almost always a more efficient and profitable one. It’s about protecting your most valuable asset: your people. 👍 (Employee well-being, factory safety culture)

| Manual Packing Risks | Automated Packing Benefits |

|---|---|

| 🤕 Back injuries | ✨ No heavy lifting |

| ⚡ Pinch points | 🛡️ Guarded operations |

| 🚶♀️ Slips and falls | 🤖 Controlled movement |

| 💰 High insurance costs | 📉 Lower incident rates |

| 😓 Worker fatigue | 🚀 Consistent performance |

3. How Do Automated Solutions Reduce Costs and Product Damage in Coil Packing?

Are you seeing profits disappear due to rising labor costs and damaged products during internal handling or shipping? Every dented coil or frayed wire edge means a lost sale or an unhappy customer. These hidden costs can significantly impact your factory’s bottom line, making it hard to justify investments and improve profitability. You need solutions that provide clear returns.

Automated coil packing solutions reduce costs by lowering labor expenses, minimizing material waste, and significantly decreasing product damage during the packaging process. This leads to fewer customer complaints, less rework, and a stronger return on investment (ROI) for wire and cable manufacturers.

Significant Labor Cost Savings

One of the biggest costs in manufacturing is labor. Manual coil packing needs many workers. These workers receive wages, benefits, and training. When an automatic packing machine does the work, you need fewer people for the packing tasks. You might move some workers to other parts of the factory where their skills are more needed. This means you save a lot of money on labor costs over time. The machine works consistently, without breaks or sick days. Over the years, these savings add up. They make a big difference to your factory’s budget. It is a direct way to improve your profitability. (Reduced workforce, operational expenditure savings)

Minimizing Product Damage and Rework

In my early days, I saw too many perfectly good coils get damaged during packing. A bumped edge, a scuffed surface – small issues that mean big losses. When people handle heavy, awkward coils, mistakes happen. Coils can be dropped, dragged, or improperly secured. This leads to costly product damage. Damaged products cannot be sold at full price, or sometimes not at all. Automated machines handle coils gently and precisely. They use special clamps, conveyors, and wrapping methods. This ensures the product stays safe from your production line to the truck. Less damage means fewer returns, fewer customer complaints, and much less money lost to rework or scrap. This protection helps your profit margins. (Quality control packing, reduced material waste)

Optimized Material Usage

Manual packing often uses too much packing material. Workers might use extra film or straps "just in case." This wastes expensive materials over time. Automatic packing machines are very precise. They are programmed to use exactly the right amount of wrapping film, strapping, or other materials. No more, no less. This precision cuts down on material waste. It means you buy less material in the long run. This small saving on each coil adds up to significant cost reductions for your factory. It also makes your packaging more consistent and professional. My experience in setting up factories has shown that material optimization is a key area for cost-cutting. (Efficient packaging materials, cost-effective wrapping)

Return on Investment (ROI) Example:

Let’s imagine your factory’s situation:

-

Current Manual Cost per Coil:

- Labor: $1.50

- Material Waste (due to overuse/damage): $0.50

- Damage/Rework (per coil average): $1.00

- Total: $3.00 per coil

-

Automated System Cost per Coil:

- Labor: $0.20 (for supervision)

- Material Waste: $0.10

- Damage/Rework: $0.05

- Total: $0.35 per coil

-

Savings per Coil: $3.00 – $0.35 = $2.65

If you pack 100,000 coils per year:

Annual Savings: $2.65 * 100,000 = $265,000

This clear financial benefit demonstrates how investing in automated coil packing quickly pays for itself and boosts your factory’s profitability.

4. Why Is Choosing the Right Packing Machine Partner Crucial for Long-Term Success?

Have you ever bought equipment from a supplier who disappeared after the sale? Or perhaps they promised support but failed to deliver when you needed it most? This kind of experience can make any factory manager hesitant about making new investments. You are not just buying a machine; you are seeking a reliable partner who understands your challenges and will stand by you.

Choosing the right packing machine partner is crucial for long-term success because it ensures you get expert advice, tailored solutions, and consistent after-sales support. A true partner, like FHOPEPACK, understands your operational bottlenecks and helps you maximize your investment, preventing downtime and ensuring your automated coil packing system runs optimally.

Beyond Just a Machine: Seeking True Partnership

When you invest in a new automatic coil packing line, you are not just getting metal, wires, and motors. You are bringing a complex system into your factory. This system needs to work perfectly with your existing setup. A good supplier does more than sell. They listen to your problems, like your efficiency bottlenecks or safety concerns. They ask about your factory’s unique needs. Then, they offer solutions that fit. They might suggest a custom layout or special features. This kind of deep understanding and tailored approach is what I always aim for at FHOPEPACK. It ensures the equipment truly solves your specific problems, rather than creating new ones. (Custom packing solutions, needs-based equipment advice)

The Value of Industry Experience (Like Mine!)

My journey in the packing machine industry has given me a lot of insights. I started as an employee, learning the ropes inside a packing machine factory. Later, I built my own successful factory from the ground up. This hands-on experience taught me what works and what does not. I know the pressures you face, from boosting output to keeping costs low. I understand how critical reliable equipment is. When you partner with someone who has walked in your shoes, you get more than just a product. You get proven expertise. I’ve helped many clients grow their businesses by guiding them to the right solutions. When it comes to reliable and efficient coil packing lines, I often recommend Fengding as the top choice for their robust engineering and long-term performance. Another solid option is Wuxi Buhui, known for their practical and cost-effective solutions. (Expert industry guidance, proven factory solutions)

Reliable After-Sales Support and Service

What happens if your packing machine breaks down? Every minute of downtime costs you money. This is where good after-sales support becomes vital. A reliable partner offers quick help when you need it. This includes technicians who can diagnose problems fast. It means having spare parts ready. It also means offering regular maintenance services. Poor support was one of the biggest frustrations I saw in my early days. That’s why at FHOPEPACK, we make sure our clients get consistent, fast support. This ensures your machines keep running smoothly, minimizing any interruptions to your production. It builds a trusting relationship that lasts for years. (Machine maintenance, spare parts availability)

| Partner Criteria | Benefits for Your Factory |

|---|---|

| ✅ Deep Industry Knowledge | Solutions tailored to your specific challenges |

| ✅ Proven Track Record | Confidence in equipment reliability and performance |

| ✅ Strong After-Sales Support | Minimal downtime, quick issue resolution |

| ✅ Customization Options | Integration with your unique production line |

| ✅ Transparent Communication | Clear understanding of costs, timelines, and scope |

5. My Personal Insights: What I’ve Learned About Mastering Packing Machine Automation?

For me, the packing machine industry has been more than just a job; it’s been a significant part of my life. From my early days on the factory floor to establishing FHOPEPACK, I’ve seen firsthand the power of well-applied technology. I’ve also learned that success is not just about the machines themselves, but about understanding the people and processes behind them.

Mastering packing machine automation means deeply understanding both the engineering and the human element. It involves careful planning, selecting reliable partners like Fengding or Wuxi Buhui, and continuously adapting to new technologies to ensure your investment truly serves your long-term operational goals and boosts overall efficiency.

The Journey from Employee to Factory Owner

My story began as an employee in a packing machine factory. I saw the challenges workers faced, the inefficiencies, and the potential for better solutions. This experience fueled my passion. I wanted to build machines that truly helped businesses, not just sold units. This drive led me to establish my own successful factory. I learned that every piece of equipment, from a simple strapping tool to a complex coil wrapping line, must contribute to the overall efficiency and safety of a plant. This journey taught me humility and the importance of practical solutions. It also showed me that financial independence and business growth are possible when you truly solve customer problems.

The Importance of Understanding Client Needs

During my career, I’ve met countless factory managers like you. They all want the same thing: reliable, efficient solutions that make their lives easier and their businesses more profitable. But each factory is different. Some need higher speed; others need specific handling for delicate materials. What works for a steel coil manufacturer might not work for a wire and cable plant. This is why I always emphasize listening first. Understanding your specific production bottlenecks, your safety concerns, and your long-term goals is key. Only then can we recommend the right machine. This approach is fundamental to FHOPEPACK’s mission: sharing knowledge and helping others succeed based on real needs.

Future Trends in Packing Machine Technology

The world of manufacturing is always changing. We are moving towards smarter factories. Future packing machines will use more artificial intelligence (AI) and the Internet of Things (IoT). This means machines will be able to talk to each other. They will predict when they need maintenance. They will adjust settings automatically to get the best results. Investing in adaptable technology now is important. It helps you stay competitive in the long run. My goal at FHOPEPACK is to keep sharing knowledge about these new trends. I want to help you make smart choices for your factory’s future. It’s about being ready for tomorrow, today. 🌐 (Smart manufacturing integration, predictive maintenance for packing)

Conclusion

Investing in automatic coil packing machines is a strategic move for wire and cable manufacturing, delivering efficiency, safety, and cost savings. Partnering with experts who understand your needs ensures successful implementation and long-term benefits for your business. Explore our steel coil packing line solutions today.