Automatic Coil Packing Machine Applications Across Metal Industries?

Have you ever looked at your packing line and felt a knot in your stomach? The slow pace, the tired workers, the constant worry about injuries or damaged products? I know that feeling. For years, I saw how manual processes choked production and ate into profits. It’s a common story in the metal industry, especially for factory managers like Michael Chen in Mexico, who grapple with heavy steel coils and wire products every single day. The truth is, relying on outdated packing methods is not just inefficient; it’s a direct threat to your bottom line and your team’s safety.

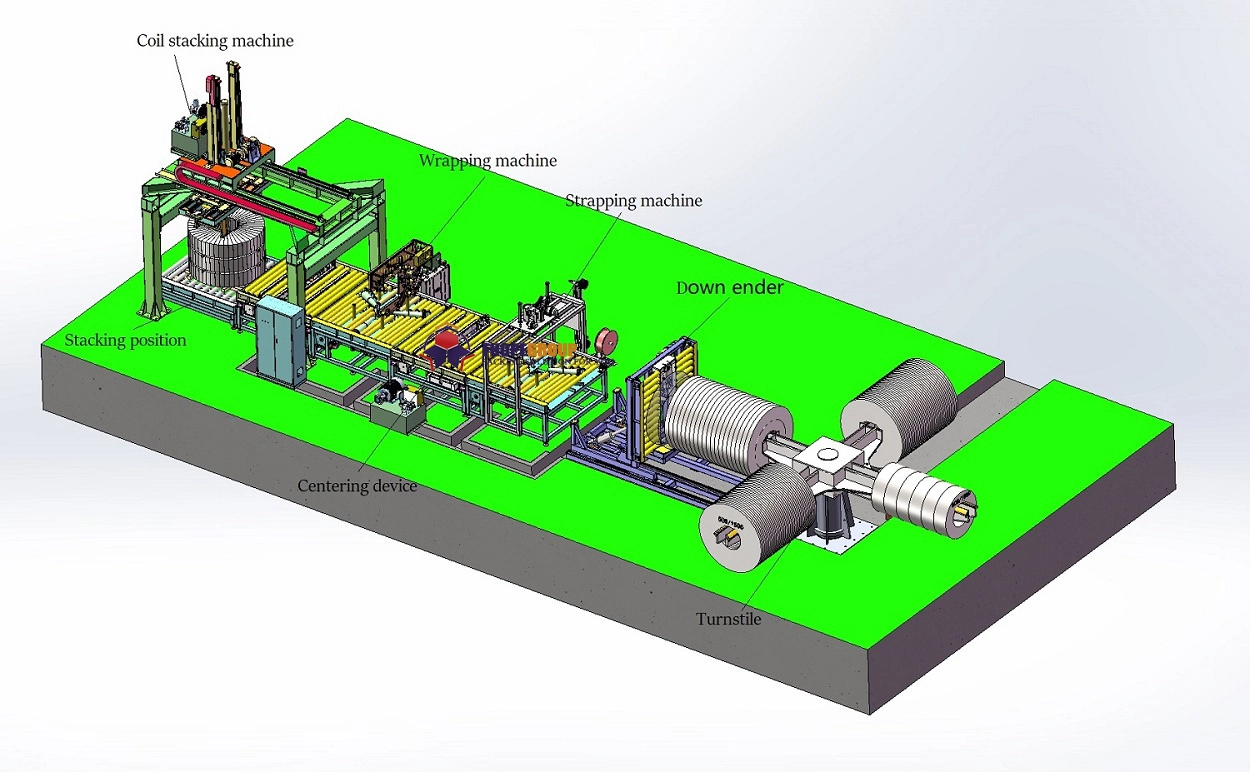

Automatic coil packing machines are essential tools across various metal industries, including steel, wire, and non-ferrous metals, because they significantly enhance operational efficiency, improve worker safety, and protect valuable products from damage. These machines streamline the end-of-line process, ensuring that heavy coils are consistently and securely wrapped, ultimately reducing labor costs and increasing overall factory output.

The metal industry is evolving fast. To stay competitive, you need solutions that not only keep up but also push you ahead. Let’s dive deeper into how automating your coil packing can truly transform your operations, solving the very challenges you face daily.

1. Why Automate Coil Packing in Today’s Metal Industry?

Imagine your packing line running like a well-oiled machine, smoothly handling heavy coils without a hitch. Now, picture the alternative: a line where workers struggle with heavy lifting, constantly facing risks, and where every packed coil takes too long. That frustration, that inefficiency, is a major pain point for many factories. It slows down delivery, increases costs, and can even lead to valuable team members leaving.

Automating coil packing in the metal industry is no longer a luxury but a necessity for overcoming labor shortages, drastically increasing production throughput, eliminating workplace injuries related to manual handling, and consistently improving product quality. This strategic move directly addresses operational bottlenecks and enhances overall factory performance, delivering a strong return on investment (ROI).

The metal industry is tough. You deal with heavy materials, tight deadlines, and constant pressure to reduce costs while boosting output. From my years working in and building packing machine factories, I have seen firsthand how much difference the right equipment makes. Manual coil packing is one of the biggest bottlenecks. It slows down everything. Workers must physically move, wrap, and secure coils. This process is not only slow but also prone to human error. Automation removes these limitations. For example, in a steel processing plant, automatic systems ensure each steel coil is wrapped at a consistent speed and with uniform tension. This level of precision is impossible to achieve manually, day in and day out. This improvement in consistency directly impacts downstream processes and customer satisfaction. (operational efficiency, production bottlenecks)

Think about worker safety. Heavy steel coils can weigh thousands of pounds. Moving them, tilting them, or wrapping them by hand creates significant injury risks. Cuts, crushing injuries, and strains are common. These incidents lead to higher insurance costs, lost workdays, and a negative impact on morale. An automatic packing machine takes the human element out of hazardous tasks. It handles the heavy lifting and secures the coil without direct human contact during the dangerous parts of the process. This dramatically reduces the risk of accidents. It makes the workplace safer. It also helps in retaining skilled workers who prefer a safer environment. (workplace safety, industrial accident prevention)

Beyond safety and speed, automation also means significant cost savings. You reduce the need for a large workforce dedicated solely to packing. This lowers labor costs. You also minimize product damage. Manual handling often results in cosmetic flaws or edge damage on coils, leading to rejections or discounts. Automated wrapping applies protective materials consistently, reducing these losses. Over time, these savings add up. They justify the initial investment in the equipment. My experience showed me that the initial cost of automation can seem high. However, the long-term benefits in efficiency, safety, and reduced waste always outweigh that initial outlay, offering a clear path to financial gains. (cost reduction strategies, ROI optimization)

2. What Types of Automatic Coil Packing Machines Suit Different Metal Products?

It’s easy to think of a packing machine as one general piece of equipment. But in the diverse world of metal manufacturing, from thick steel plates to delicate wire, "one size fits all" simply doesn’t work. Choosing the wrong machine can be just as problematic as having no machine at all. It can create new bottlenecks or fail to protect your specific product properly, leaving you frustrated and your investment underutilized.

Different automatic coil packing machines are specifically engineered to handle the varied shapes, sizes, and weights of metal products encountered across the industry. Horizontal coil wrappers are ideal for large, heavy steel and aluminum coils, while vertical wrappers are designed for narrower, often stacked coils. Specialized wire coil packing lines offer solutions that include compression and strapping before wrapping, ensuring optimal protection and handling for smaller gauge materials.

Understanding the different types of automatic packing machines is crucial. This is how you ensure your investment truly meets your operational needs. I’ve helped countless clients, including factory managers like Michael Chen, choose the perfect machine for their specific products. Let’s break down the main categories:

Horizontal Coil Wrappers 🔄

Horizontal coil wrappers are the workhorses for heavy-duty metal coils. These machines rotate the wrapping material around the circumference of a coil as it lies flat on a conveyor or a loading system.

- They are ideal for large steel coils, aluminum coils, and other heavy non-ferrous metal coils.

- The horizontal design is robust. It can handle extreme weights and dimensions.

- This method provides excellent protection against dust, moisture, and impact during storage and transit.

- Often integrated with automatic coil conveying and stacking systems.

For example, a steel mill producing hot-rolled or cold-rolled coils would almost certainly use a horizontal coil wrapper. These coils are typically very wide and heavy. The horizontal machine applies multiple layers of protective film, paper, or stretch wrap, securing the entire outer surface. This prevents edge damage and surface scratches. (heavy duty metal packaging, steel coil wrapping solutions)

Vertical Coil Wrappers ⬆️

Vertical coil wrappers are designed for coils that are either narrower or are intended to be stored and transported vertically. In this configuration, the coil stands upright while the wrapping material is applied.

- Commonly used for smaller steel coils, some types of aluminum coils, and specialized non-ferrous metals.

- They often save floor space compared to horizontal systems, as the coil footprint is smaller.

- Can be integrated into lines where coils are handled vertically throughout the process.

- Provides similar protection against environmental factors.

A factory processing narrower gauge steel strip, for instance, might benefit more from a vertical wrapper. These coils can be more easily stacked vertically, and the machine fits more compactly into a production line. The vertical design makes it easier to integrate with automated crane systems that load and unload coils from above. (vertical wrapping systems, space-saving packaging machinery)

Wire Coil Packing Lines 🧶

Wire coils have unique requirements. They are often smaller in diameter but can be very heavy due to their density. They also need to be tightly bound to prevent unraveling.

- These lines typically involve compression to compact the wire coil, strapping to secure it, and then often wrapping for environmental protection.

- They are critical for industries producing steel wire, copper wire, welding wire, and other similar products.

- Automation in these lines significantly reduces manual labor and improves package integrity.

- Can include multiple stations: weighing, banding, strapping, and wrapping.

I recall a client who struggled with wire coils constantly unraveling during shipment. Their manual strapping methods were inconsistent. We implemented an automatic wire coil packing line. It not only compressed the coils uniformly but also applied multiple steel straps with precise tension before wrapping them. This virtually eliminated product damage and improved customer satisfaction immensely. This type of solution showcases the power of specialized automation. (wire coil packaging automation, specialized packing machinery)

Selecting the correct type is the first step toward unlocking true efficiency. It depends entirely on your specific product, its dimensions, weight, and your existing production layout.

3. How Do Automatic Packing Machines Tackle Metal Industry’s Toughest Challenges?

Michael Chen, like many factory managers, is under immense pressure. He constantly deals with production bottlenecks, worries about worker safety, and cringes at any product damage. These aren’t minor inconveniences; they directly impact the factory’s profitability and reputation. When customers receive damaged goods, or when production stalls, it’s a huge problem.

Automatic packing machines are engineered to directly address the most persistent challenges in the metal industry by providing consistent product protection, thereby reducing damage and customer complaints. They also drastically enhance operational safety by minimizing manual handling of heavy items and significantly improve production throughput by automating end-of-line processes, integrating seamlessly into existing manufacturing workflows.

Let’s look at how these machines act as powerful solutions to these tough industry challenges. From my perspective, having worked on the factory floor and then building machines, I understand the real-world impact.

Product Protection & Damage Reduction ✅

One of the biggest headaches is product damage. Steel coils, even robust ones, can suffer damage to their edges or surfaces during internal transport or manual packing. This leads to costly rejections, rework, or customer dissatisfaction. Automatic machines apply wrapping materials with consistent tension and overlap.

- Edge Protection: Precisely wrapped layers prevent nicks and dings on coil edges, a common damage point.

- Surface Integrity: Uniform wrapping protects against scratches, dust, moisture, and even rust during storage and transit.

- Consistent Quality: Machines don’t get tired or distracted, ensuring every coil receives the same high level of protection.

I remember a time when a client was losing a significant percentage of their profits due to edge damage on their slit coils. Manual wrapping was simply not consistent enough. After installing an automated horizontal wrapper, their damage rates plummeted. This not only saved them money but also improved their customer relationships, as product quality became more reliable. (reducing product damage, quality control in packaging)

Enhanced Safety & Reduced Worker Strain 👷♂️

The risks associated with manually handling heavy coils are undeniable. Automation fundamentally changes this.

- Eliminates Heavy Lifting: Machines take over the strenuous and dangerous task of moving and positioning coils.

- Reduces Repetitive Strain Injuries: Repetitive motions involved in manual strapping and wrapping are gone, leading to fewer musculoskeletal disorders among workers.

- Fewer Accidents: By creating a barrier between workers and moving heavy loads, the chance of crushing injuries or other serious accidents drops dramatically.

Creating a safer workplace is not just about compliance; it’s about valuing your team. When workers feel safe, morale improves, and productivity can even increase. I’ve seen this firsthand: a factory that invests in safety often sees a more engaged and loyal workforce. (workplace safety solutions, industrial automation benefits)

Streamlined Workflow & Throughput Improvement 🚀

Manual packing is often the slowest part of a production line. It creates a bottleneck that limits overall output.

- Consistent Speed: Machines operate at a steady, predictable pace, eliminating human-induced slowdowns.

- Increased Capacity: Automatic systems can process coils much faster than manual methods, significantly boosting daily output.

- Seamless Integration: Modern machines can be integrated with upstream and downstream equipment, creating a continuous, automated flow from production to dispatch.

This increase in efficiency directly translates to faster order fulfillment and the ability to take on more business. For a factory manager in Mexico, like Michael, faster throughput means meeting demanding delivery schedules and gaining a competitive edge. It’s about getting more product out the door, faster, without compromising quality. (manufacturing throughput, end-of-line automation)

4. What Key Factors Should You Consider When Choosing an Automatic Coil Packing Solution?

Choosing the right automatic coil packing machine is a big decision. It’s a significant investment, and for someone like Michael Chen, who has experienced supplier trust issues, it can feel daunting. The wrong choice can lead to wasted money, ongoing operational headaches, and a missed opportunity to truly improve your factory. You need a partner you can trust, not just a seller.

When selecting an automatic coil packing solution, it is crucial to prioritize machine reliability and durability, ensuring it withstands rigorous industrial environments. Equally important is the supplier’s proven industry expertise and commitment to robust after-sales support, including parts and service. Consider customization options for seamless integration into your specific factory layout and evaluate the clear return on investment (ROI) that the solution promises to deliver.

From my journey starting as an employee to founding FHOPEPACK, I’ve learned that a successful investment in machinery goes beyond the machine itself. It’s about the whole package.

Reliability and Durability 🛡️

In metal industries, equipment faces harsh conditions. Dust, heavy loads, and continuous operation demand machines built to last.

- Robust Construction: Look for heavy-duty materials and strong engineering. The machine should be able to withstand constant use without frequent breakdowns.

- High-Quality Components: Key parts, like motors, sensors, and control systems, should be from reputable manufacturers. This ensures longevity and consistent performance.

- Minimal Downtime: A reliable machine means less time spent on repairs and maintenance, maximizing your production uptime.

A machine that constantly breaks down is not an asset; it’s a liability. My philosophy at FHOPEPACK has always been to build equipment that factory managers can depend on, day in and day out, even in demanding environments like those in Mexico. (industrial equipment durability, reliable packing machinery)

Supplier Expertise & After-Sales Support 🤝

This is where true partnership comes in. A good supplier offers more than just equipment.

- Deep Industry Knowledge: Does the supplier understand the nuances of coil handling, different metal types, and your specific production challenges? This is where FHOPEPACK stands out, with my background as a packing machine engineer who built a successful factory.

- Customization Capabilities: Can they tailor a solution to your unique coil dimensions, weight, and factory layout, rather than offering a generic product?

- Comprehensive After-Sales Service: This includes installation, training for your team, readily available spare parts, and responsive technical support. What happens if something goes wrong? You need to know help is just a call away.

Michael Chen’s concern about "supplier trust crisis" is very real. I’ve heard too many stories about companies that are great at selling but disappear when you need help. At FHOPEPACK, we believe in building long-term relationships, sharing our expertise, and ensuring our clients succeed. This includes offering strong local support options wherever possible, to ensure quick response times for our international clients. (packaging machine suppliers, after-sales service importance)

Integration and Scalability 🔗

Your new packing machine should fit seamlessly into your existing production line and be ready for future growth.

- Smooth Workflow Integration: Discuss how the machine will connect with your existing conveyors, cranes, and data systems.

- Modular Design: Can the system be expanded or upgraded in the future to meet changing production demands?

- Ease of Operation: The controls should be intuitive, and training should be straightforward for your team.

A well-integrated system maximizes efficiency. It avoids creating new bottlenecks in other parts of your factory. (factory automation integration, scalable production solutions)

Clear Return on Investment (ROI) 💰

Before any major investment, a clear financial justification is essential.

- Cost Savings Analysis: Quantify reductions in labor costs, material waste, and product damage.

- Productivity Gains: Estimate the increase in throughput and how it translates to higher revenue.

- Safety Benefits: While harder to quantify directly, improved safety reduces indirect costs like insurance premiums and absenteeism.

A good supplier will help you calculate the ROI. They will show you how the investment will pay for itself and start contributing to your profits. This transparency is key to building trust and making a confident decision. (ROI calculation for industrial equipment, cost-benefit analysis)

Conclusion

Automating coil packing addresses critical challenges in metal industries by boosting safety, efficiency, and product integrity. Choosing the right partner and machine ensures a strong return on your investment, securing your factory’s future. For more insights into optimizing your operations, explore our steel coil packing line solutions.